Pressing switching waterway mechanism

A waterway and water inlet technology, applied in mechanical equipment, water supply devices, water supply mains, etc., can solve the problems of large switching force, large space occupation, inconvenient switching, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

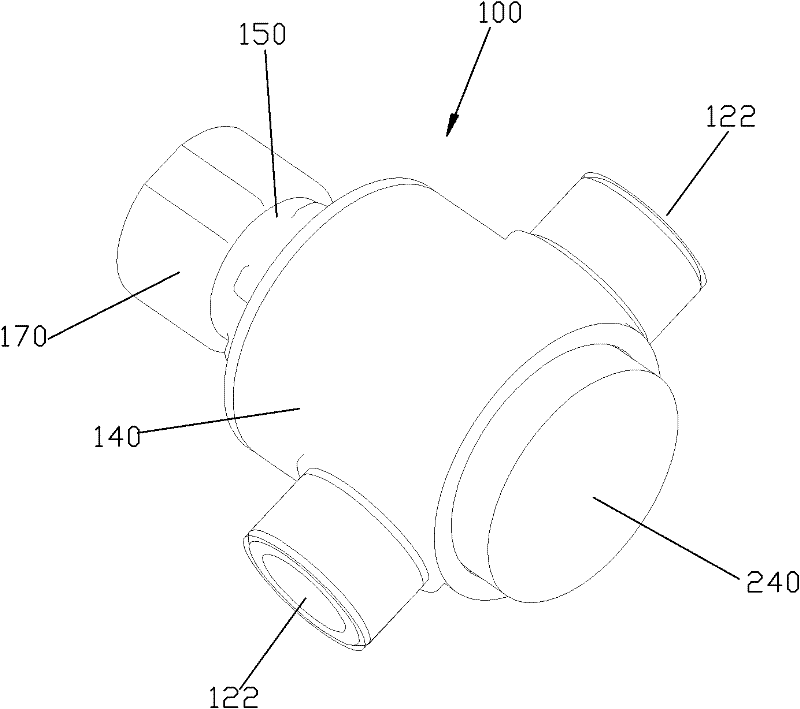

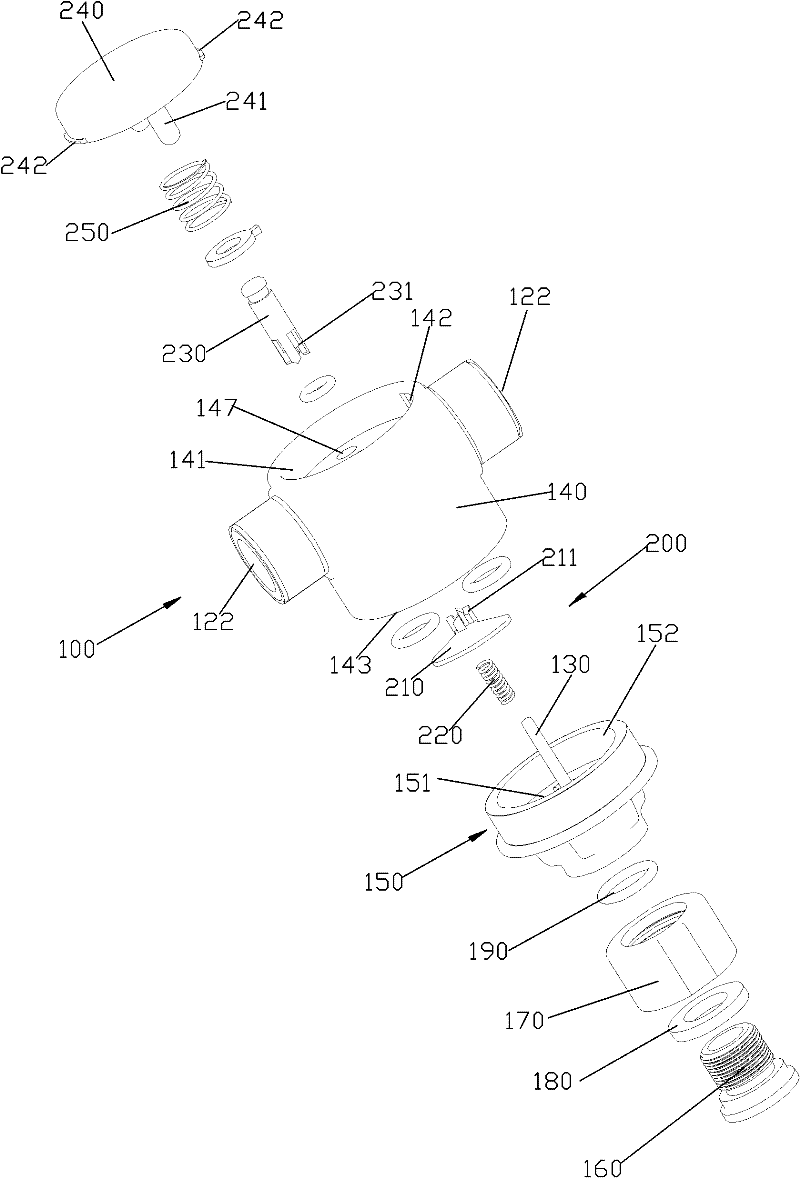

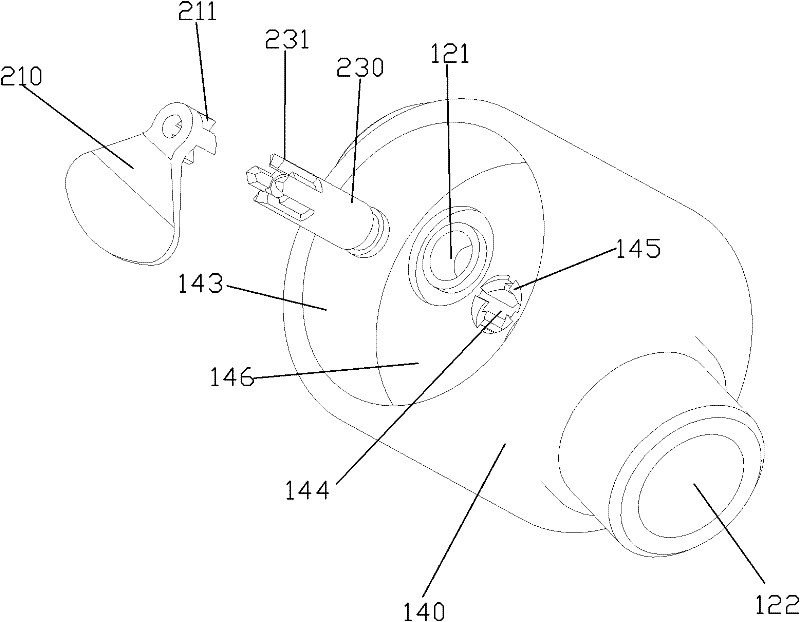

[0040] Please check Figure 1 to Figure 8 , press to switch the waterway mechanism, which includes a valve body 100 and a switching mechanism.

[0041] The valve body 100 includes a main body 140 , an upper cover 150 , a joint 160 , a joint nut 170 , a washer 180 and a sealing ring 190 .

[0042] The top surface of the main body 140 is recessed to form a water outlet chamber 143 , and the bottom surface of the water outlet chamber 143 is a switching surface 146 . The upper cover 150 includes a top wall 151 and a peripheral wall 152 extending downward from a periphery of the top wall 151 . A guide shaft 130 is fixed at the center of the bottom surface of the bottom wall 151 . The peripheral wall 152 and the water outlet cavity 143 are sealed and fixed together, so that the main body 140 and the upper cover 150 are sealed and fixed together. The bottom surface of the main body 140 is recessed to form an assembly groove 141 , and an axial positioning groove 142 is provided on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com