Pen making machine

A pen-making machine and pen holder technology, applied in the field of pen-making, can solve the problems of high manual assembly cost, increase the production cost of assembly manufacturers, waste, etc., and achieve the effect of stable and reliable equipment operation, fast and effective connection, and stable working state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

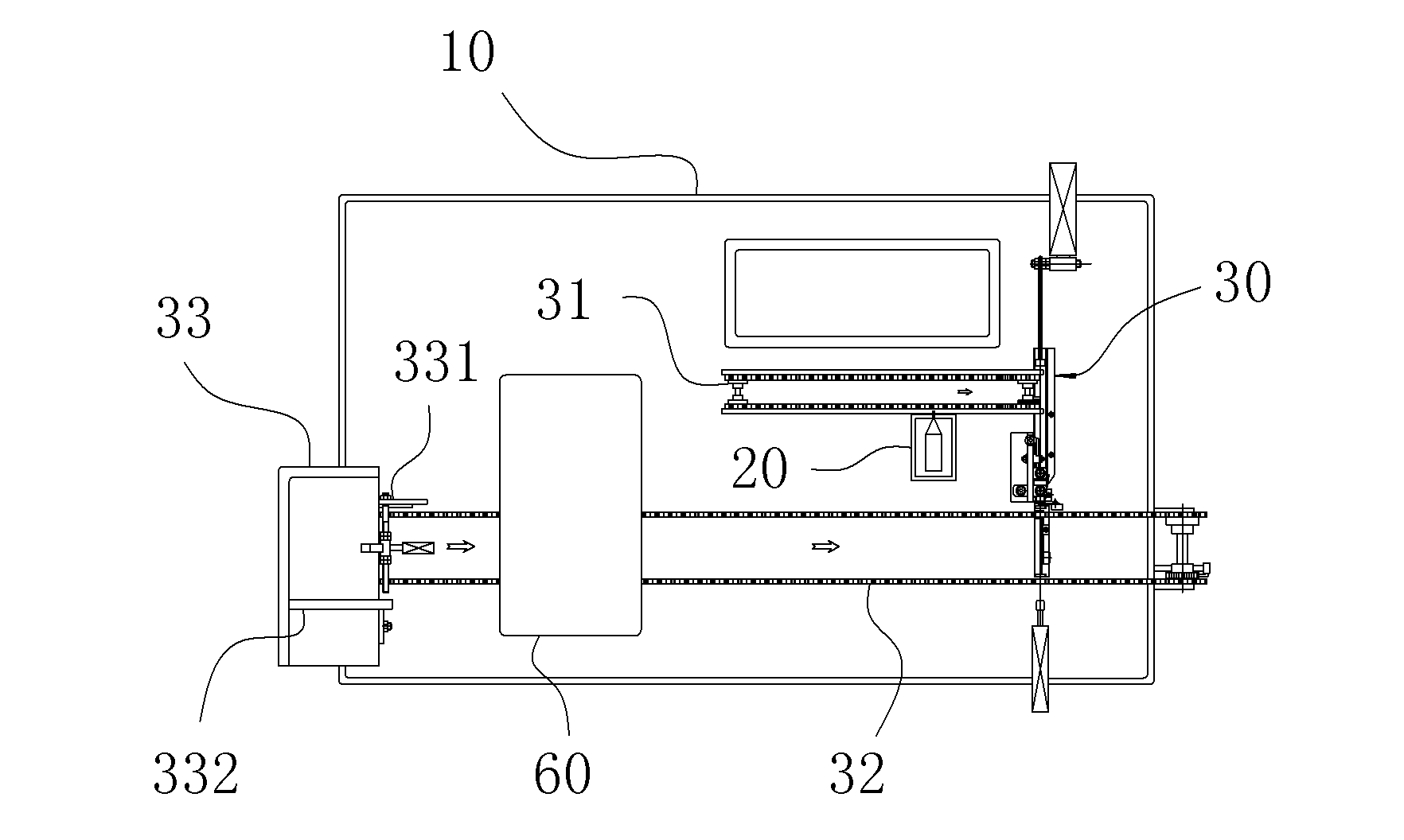

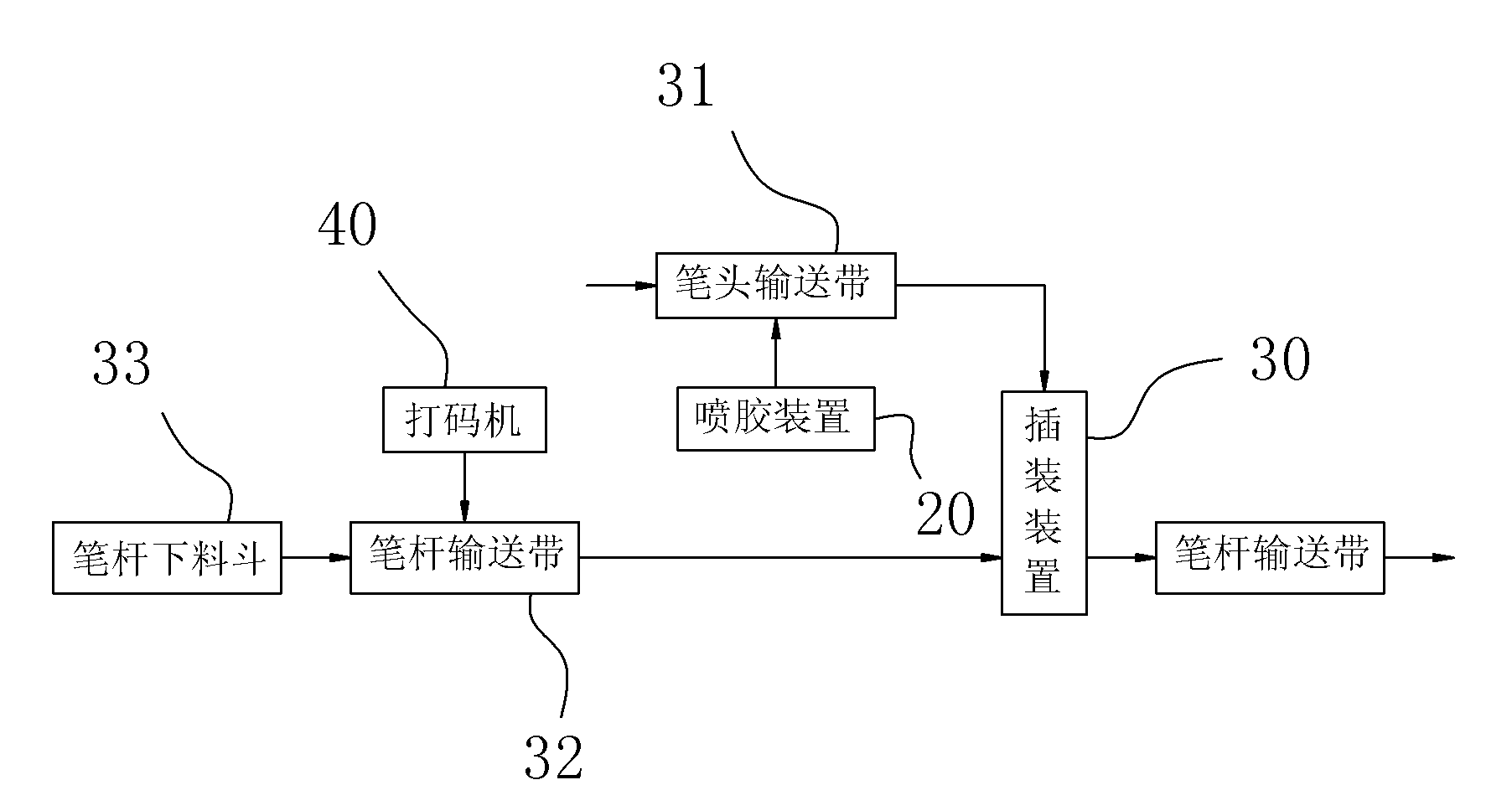

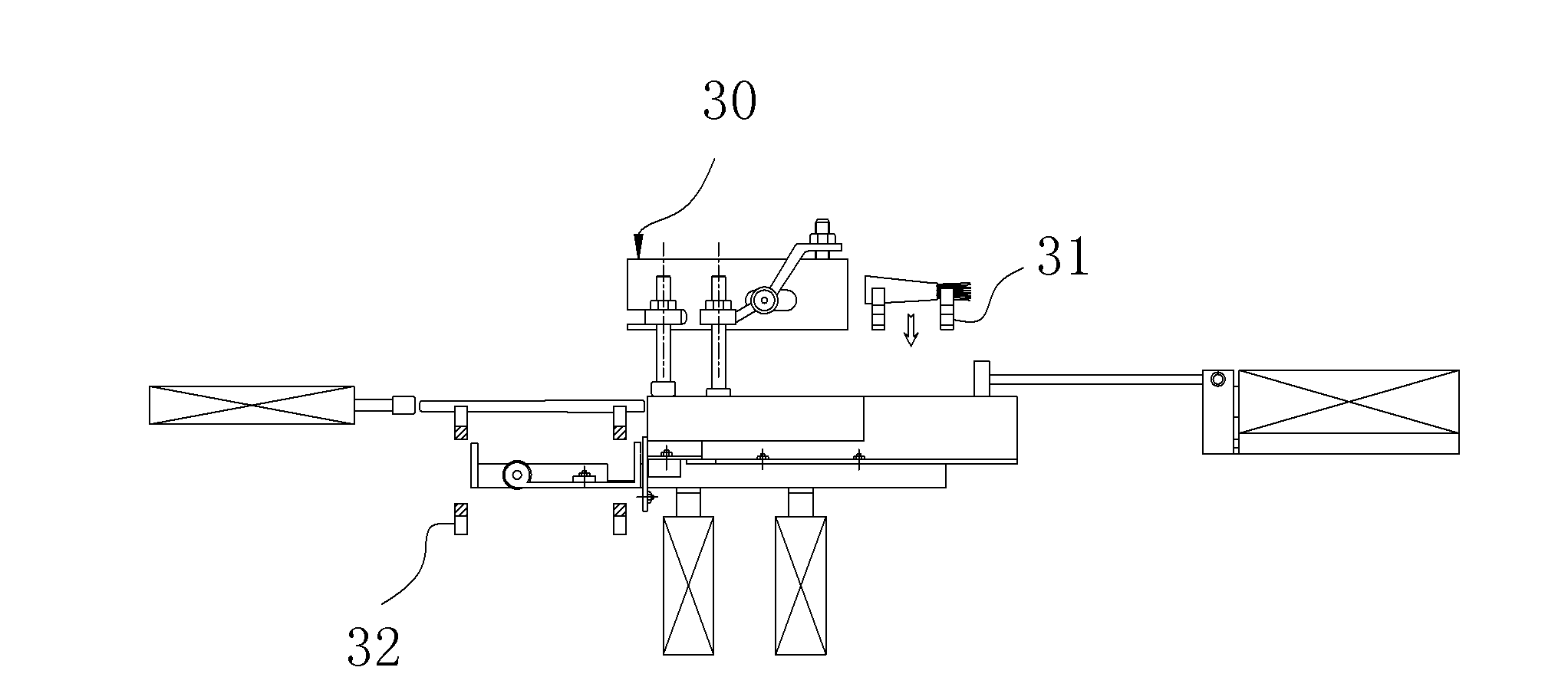

[0014] A pen-making machine, comprising a frame 10, the frame 10 is provided with a nib glue spraying mechanism 20 and a plug-in device 30 for performing plugging of the nib and the pen holder, and the plug-in device 30 includes a The nib conveying mechanism 31 of the nib to be plugged, the nib glue spraying mechanism 20 is placed on the side of the nib conveying mechanism 31, and the glue spraying port of the nib glue spraying mechanism 20 points to the pen to be plugged on the nib conveying mechanism 31. Inside the cavity of the nib, such as Figure 1-2 shown.

[0015] Further, in order to improve the working efficiency of the present invention, the described plugging device 30 also includes a pen holder conveying mechanism 32, and the feed port of the pen holder conveying mechanism 32 is provided with a pen holder lower hopper 33 for placing the pen holder to be inserted. The pen holder lower hopper 33 is provided with a discharge valve 331 for controlling the falling of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com