Patents

Literature

33results about How to "Effective working status" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

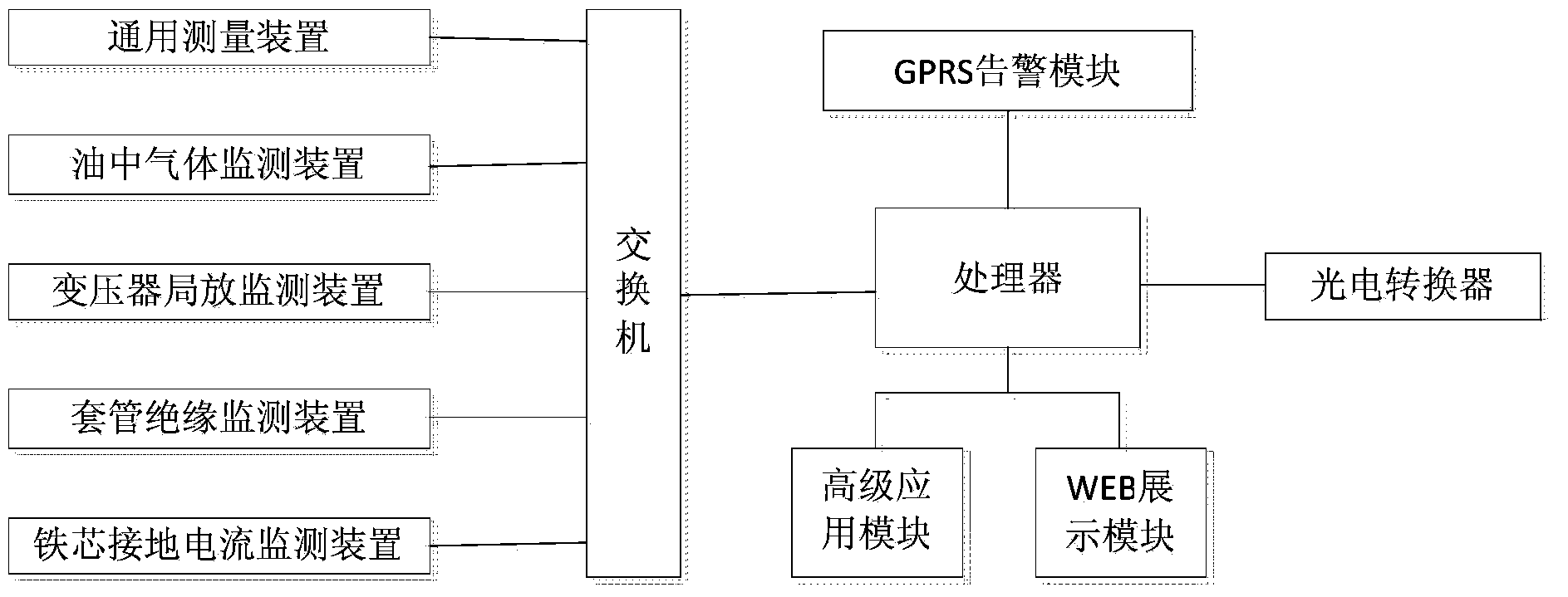

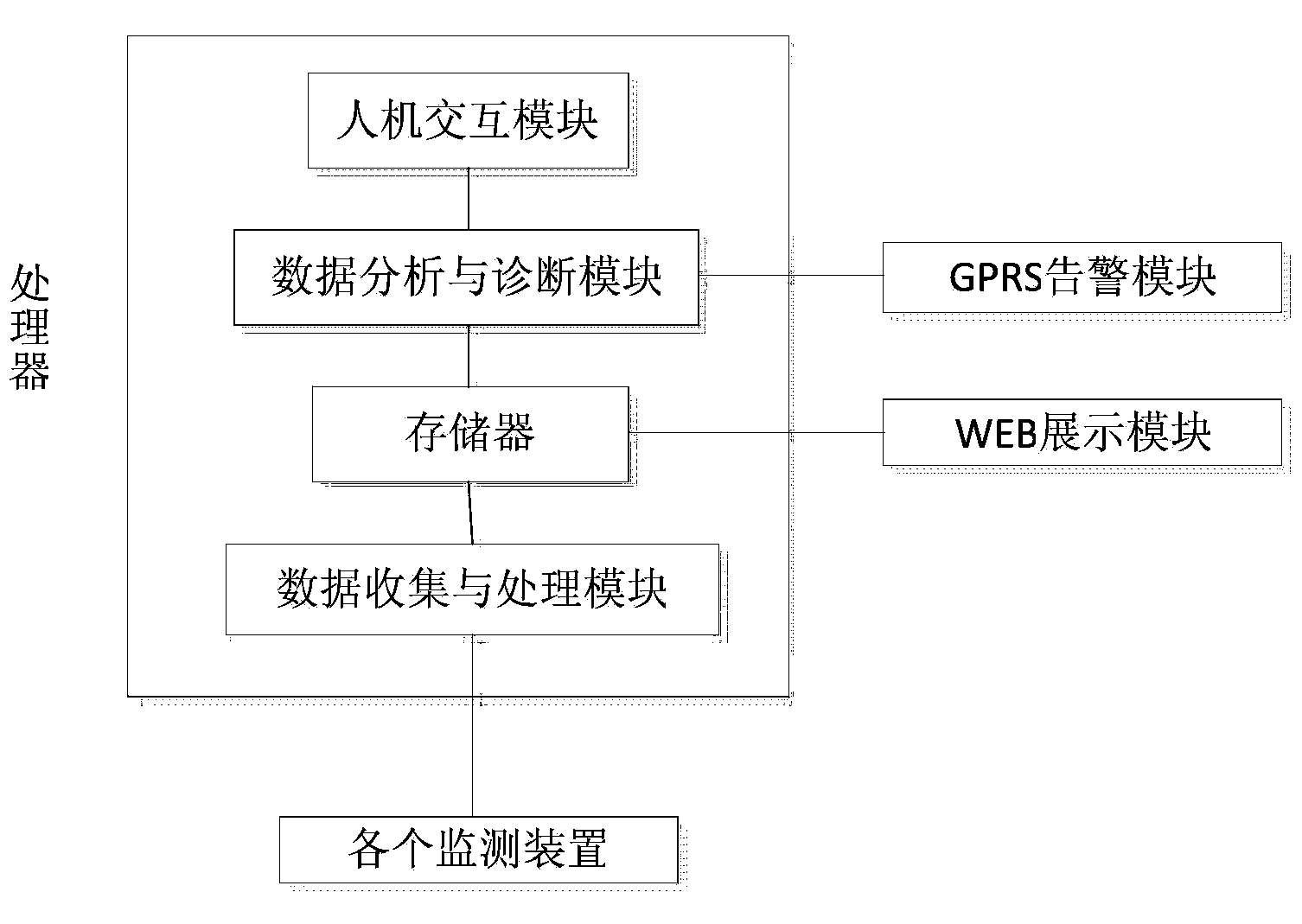

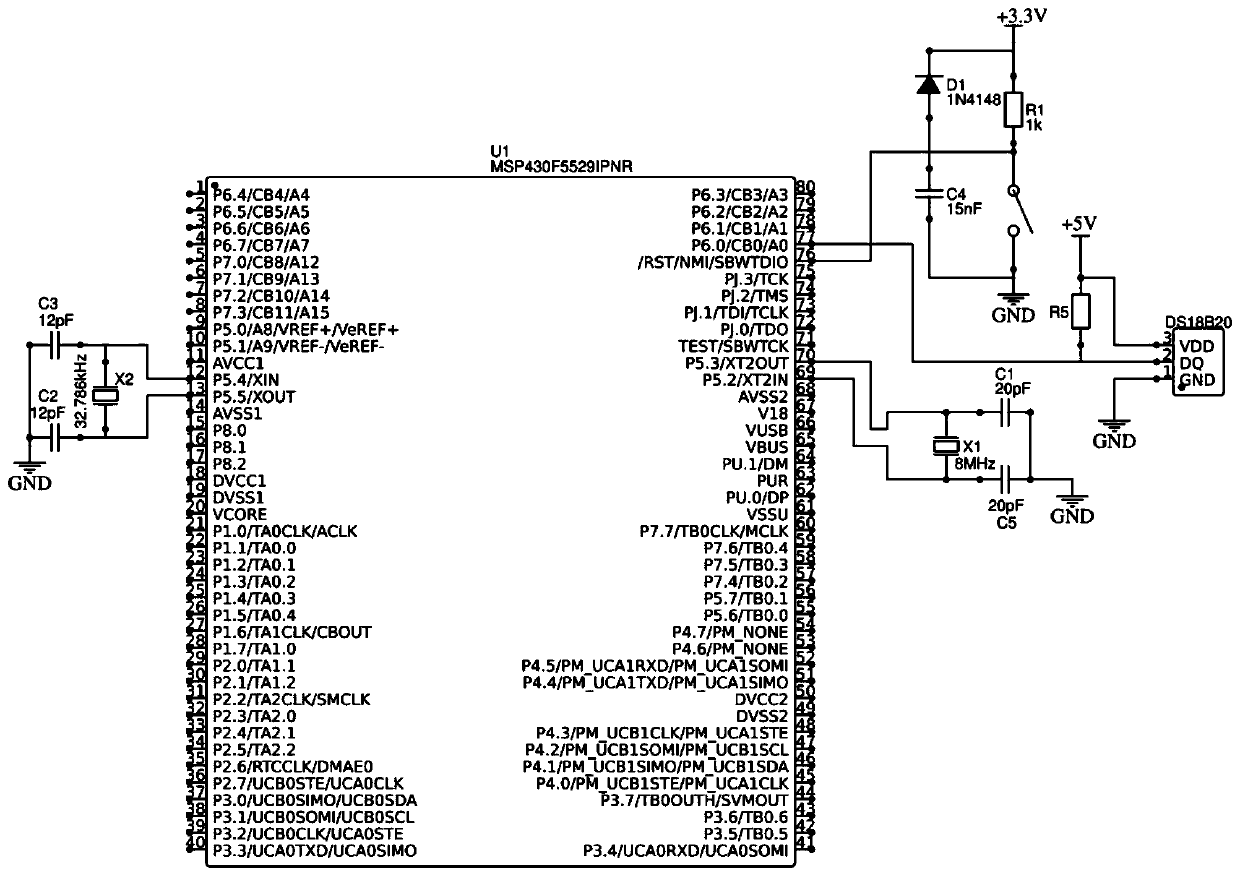

System and method for intelligently monitoring state information of transformer

InactiveCN103512619AEffective working statusComprehensive monitoring parametersElectrical testingTransmissionMeasurement deviceTransformer

The invention discloses a system for intelligently monitoring state information of a transformer. The system comprises a universal measurement device, a gas-in-oil monitoring device, a transformer partial discharge monitoring device, a sleeve insulation monitoring device, an iron core grounding current monitoring device, an exchanger and a processor, wherein each monitoring device is respectively connected with the processor through marking interfaces of the exchanger to transmit monitored various signals of the transformer to the processor for analyzing and processing; the processor is used for carrying out fault diagnosis and risk evaluation on the operating condition of the transformer on the basis of a preset transformer fault diagnosis algorithm and gives an alarm when a fault is occurred; meanwhile, a standard communication protocol, namely, an IEC61850 protocol, is adopted between each monitoring device and the processor. The system and a method have comprehensive monitoring parameters, are easy for integration and have strong independence.

Owner:HAINAN POWER GRID CO LTD ELECTRIC POWER RES INST +1

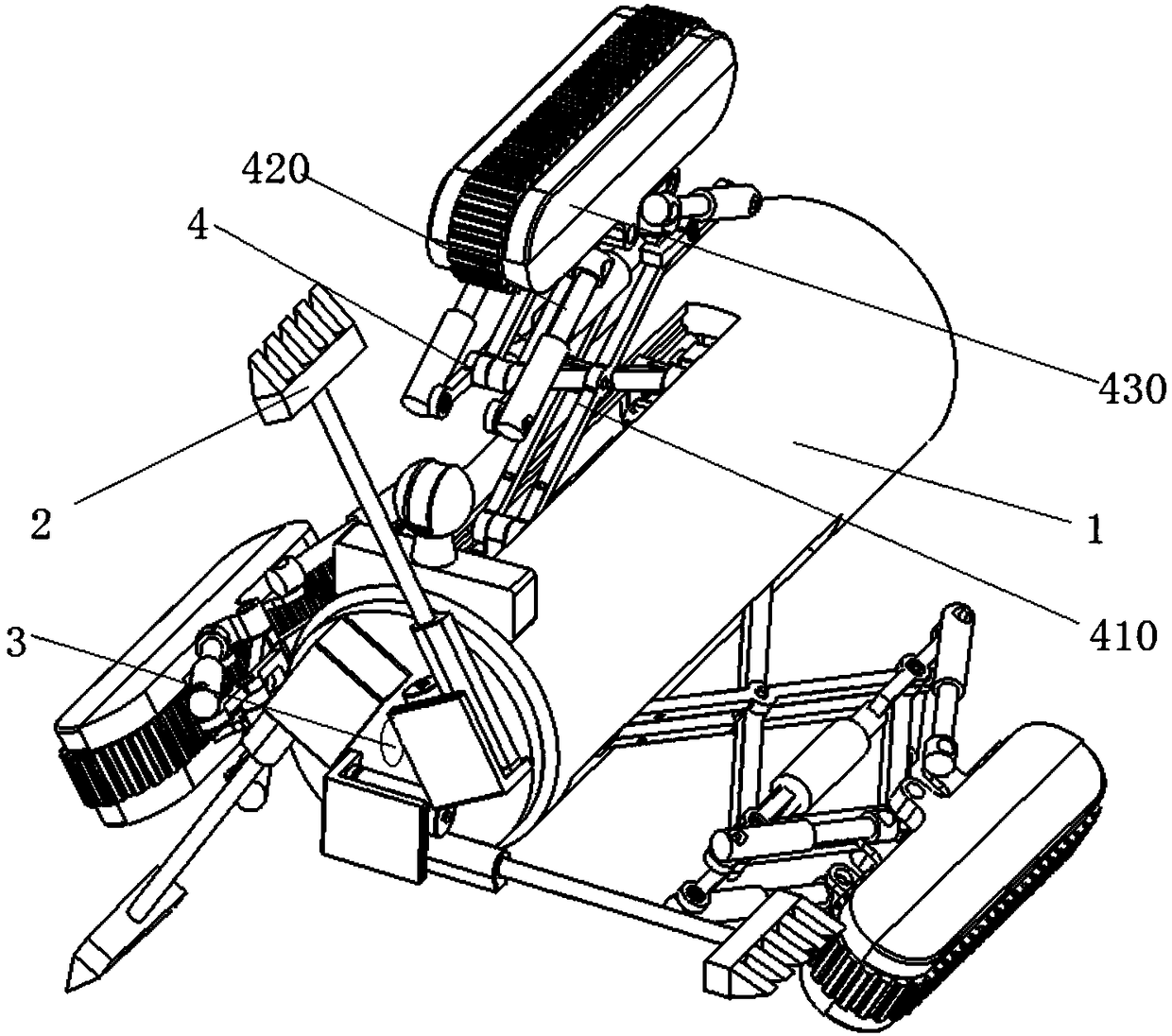

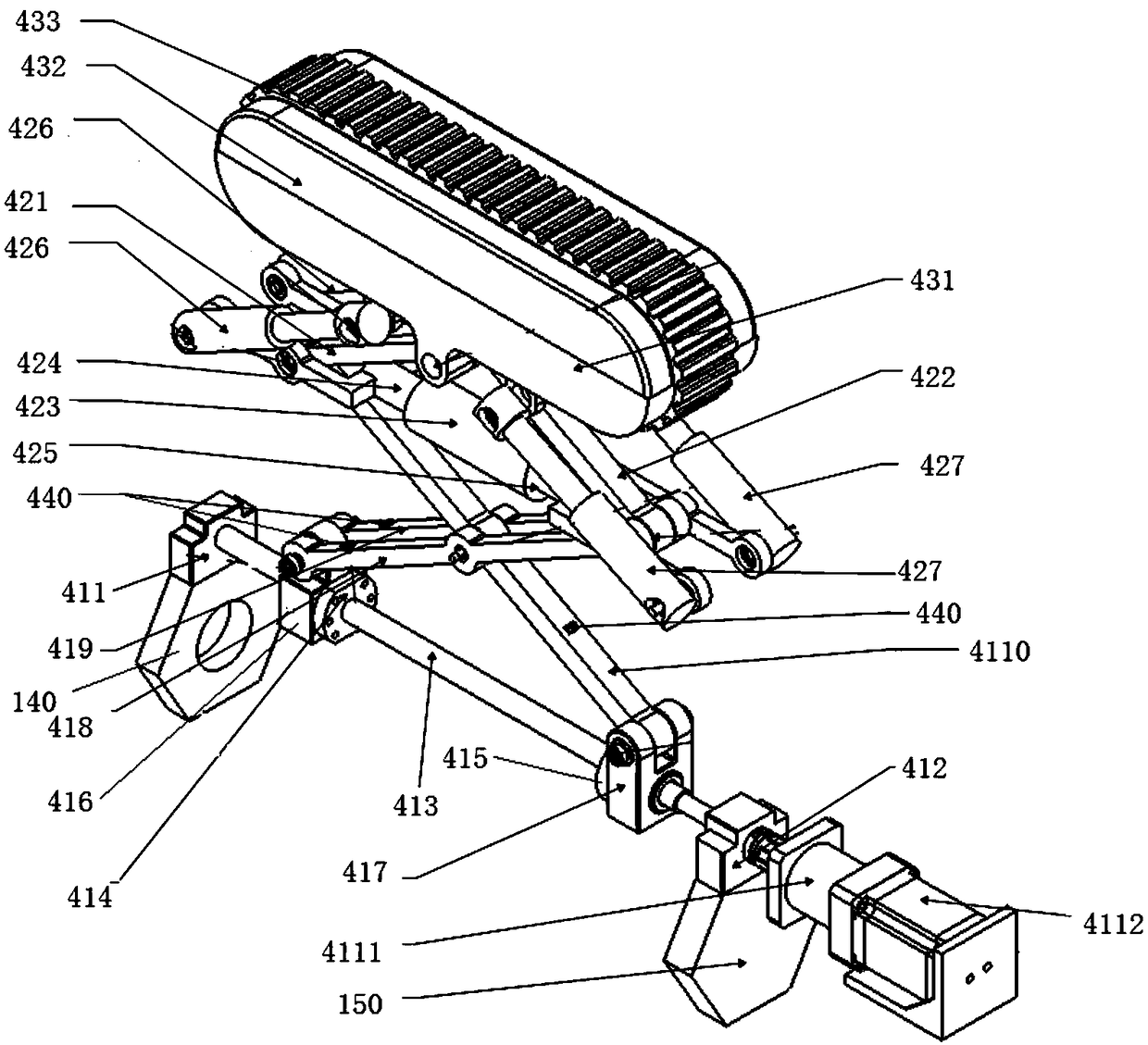

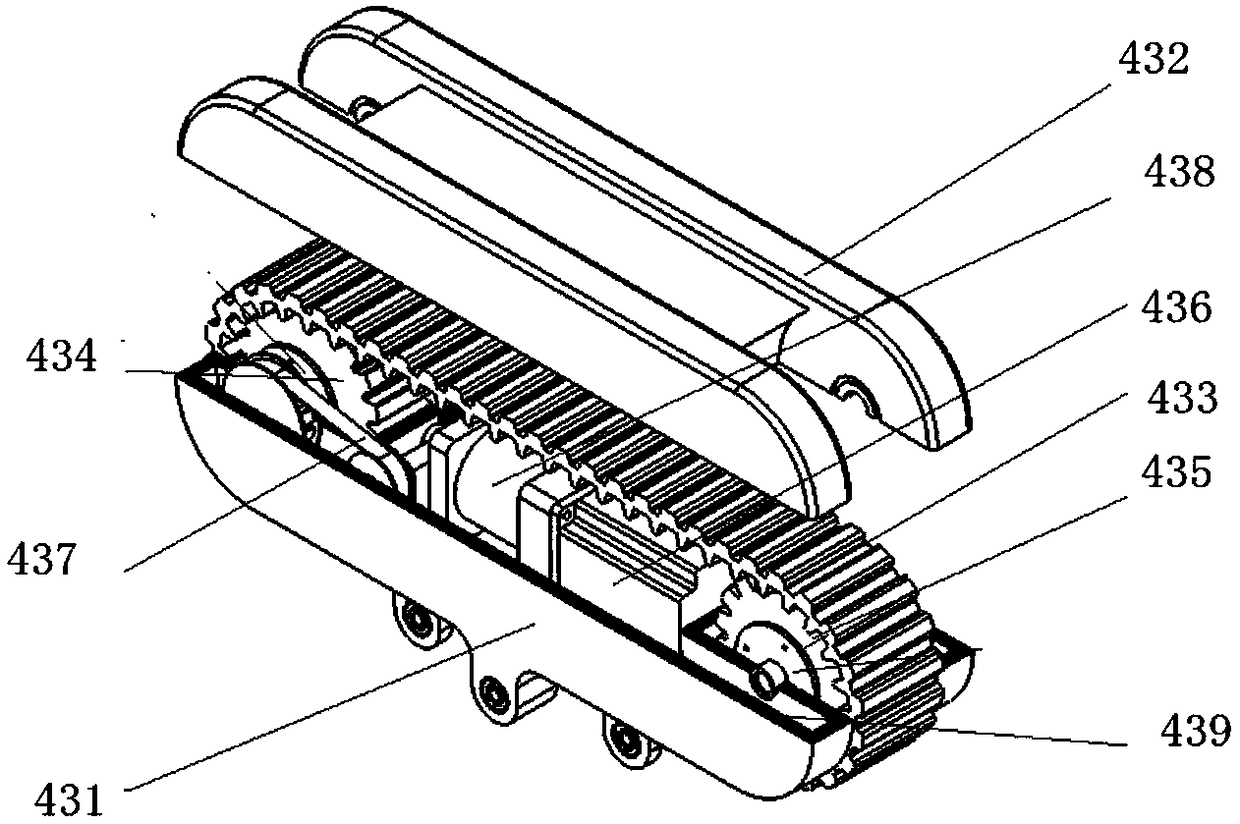

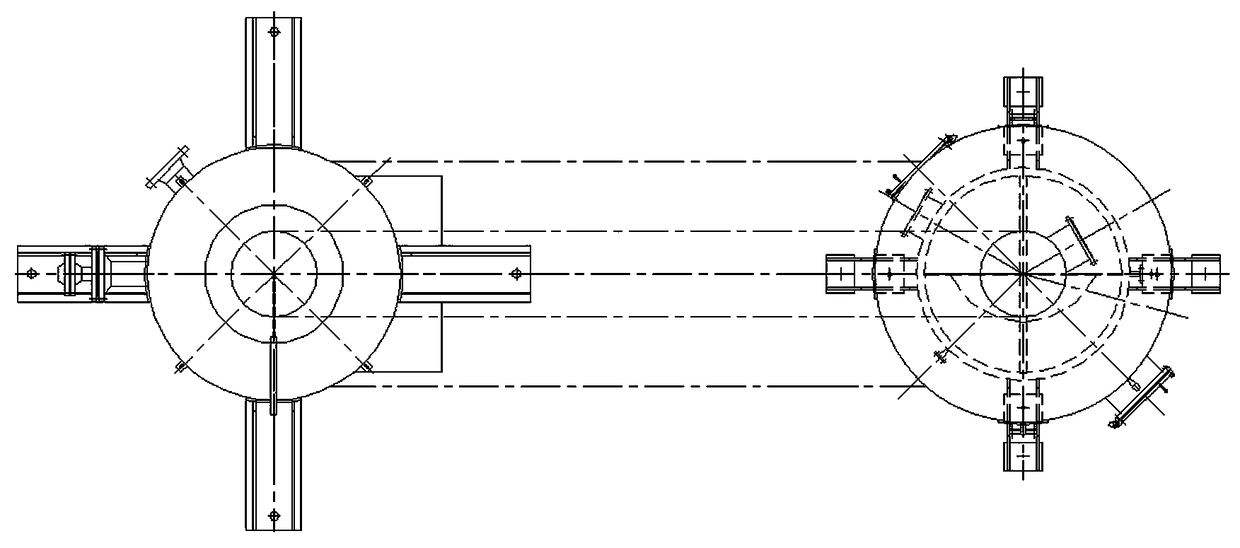

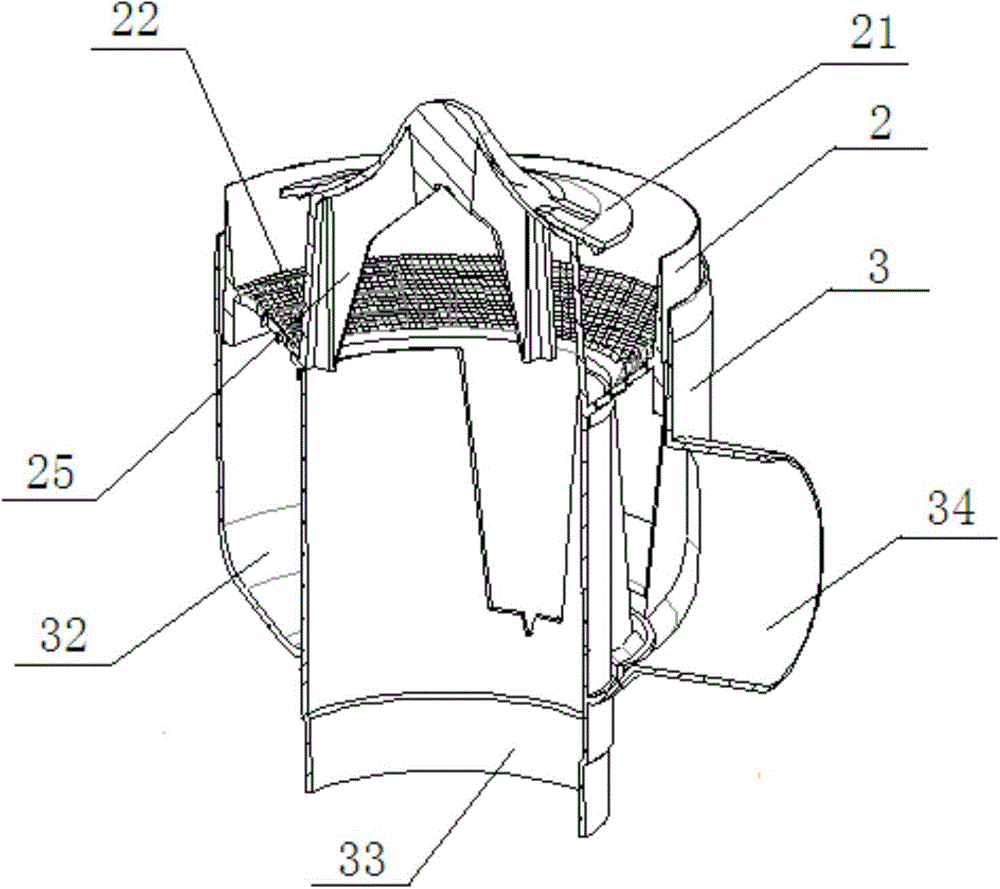

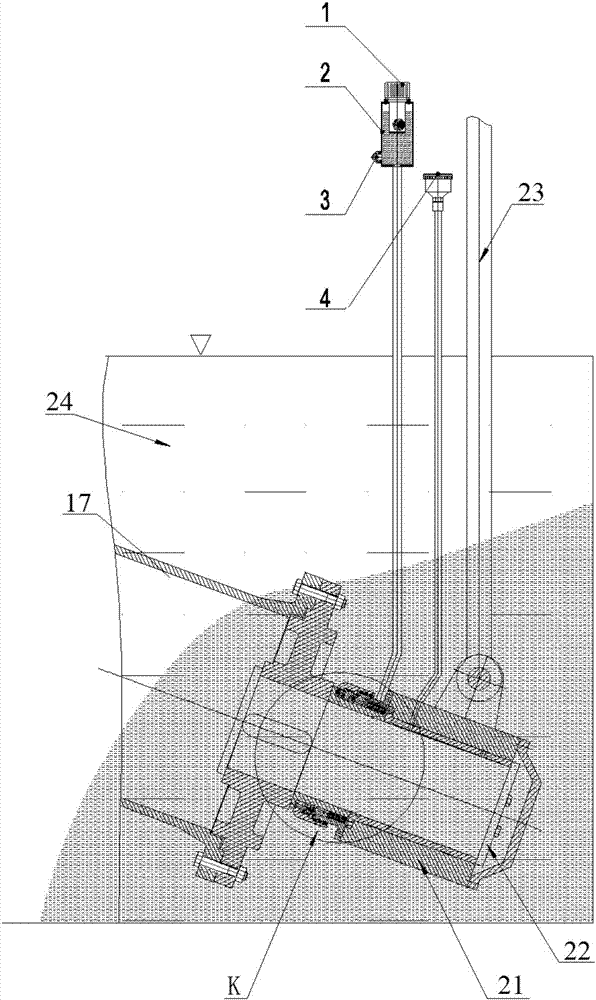

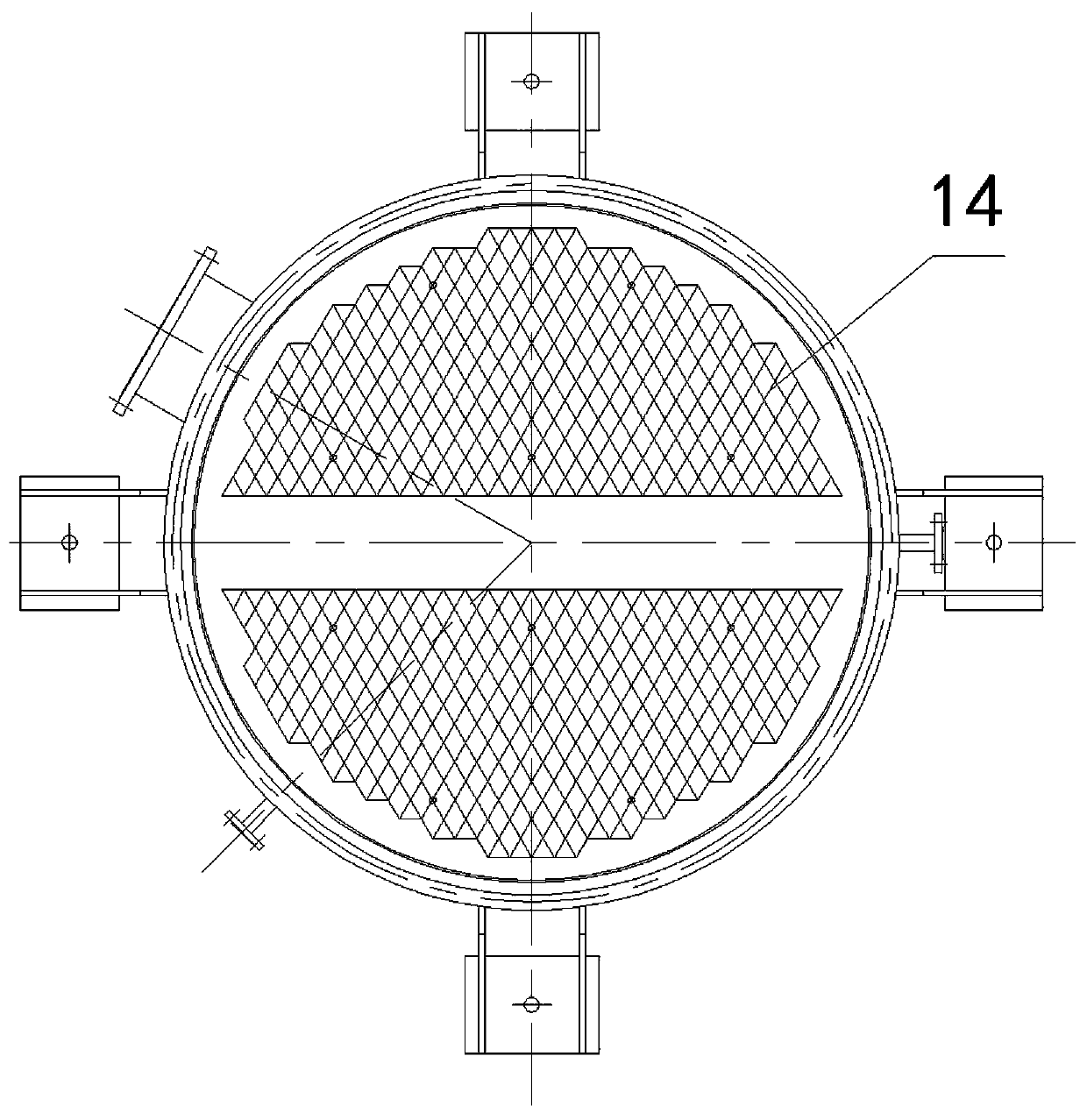

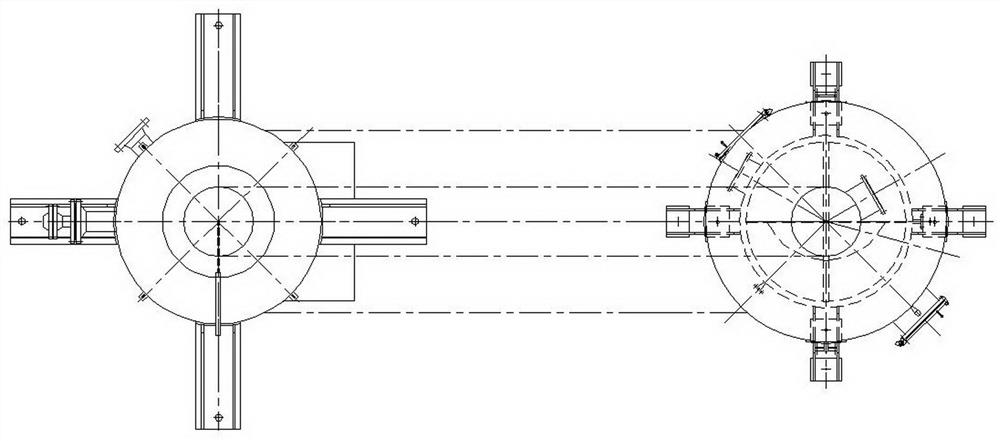

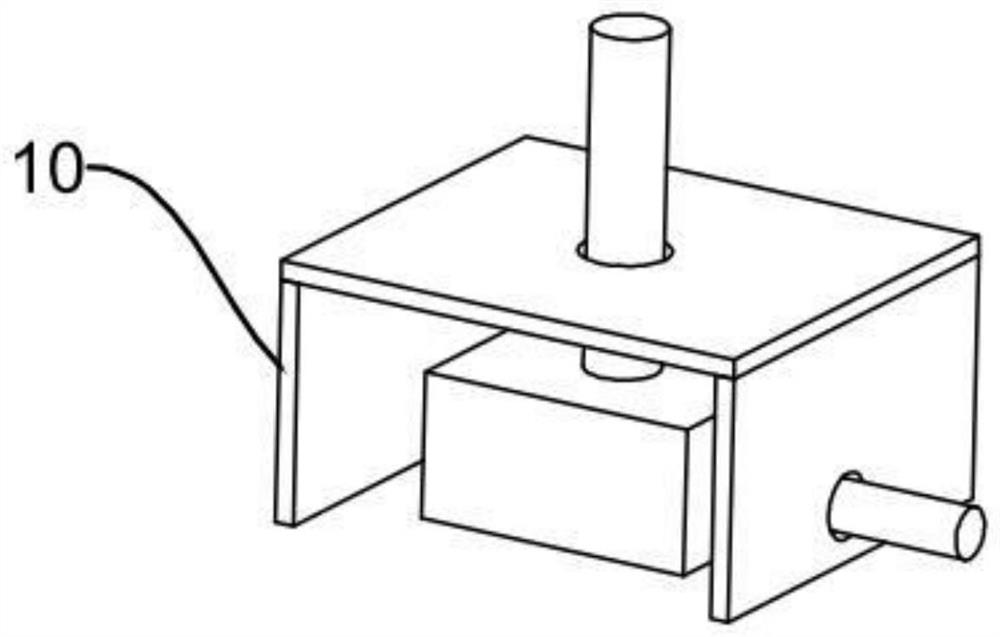

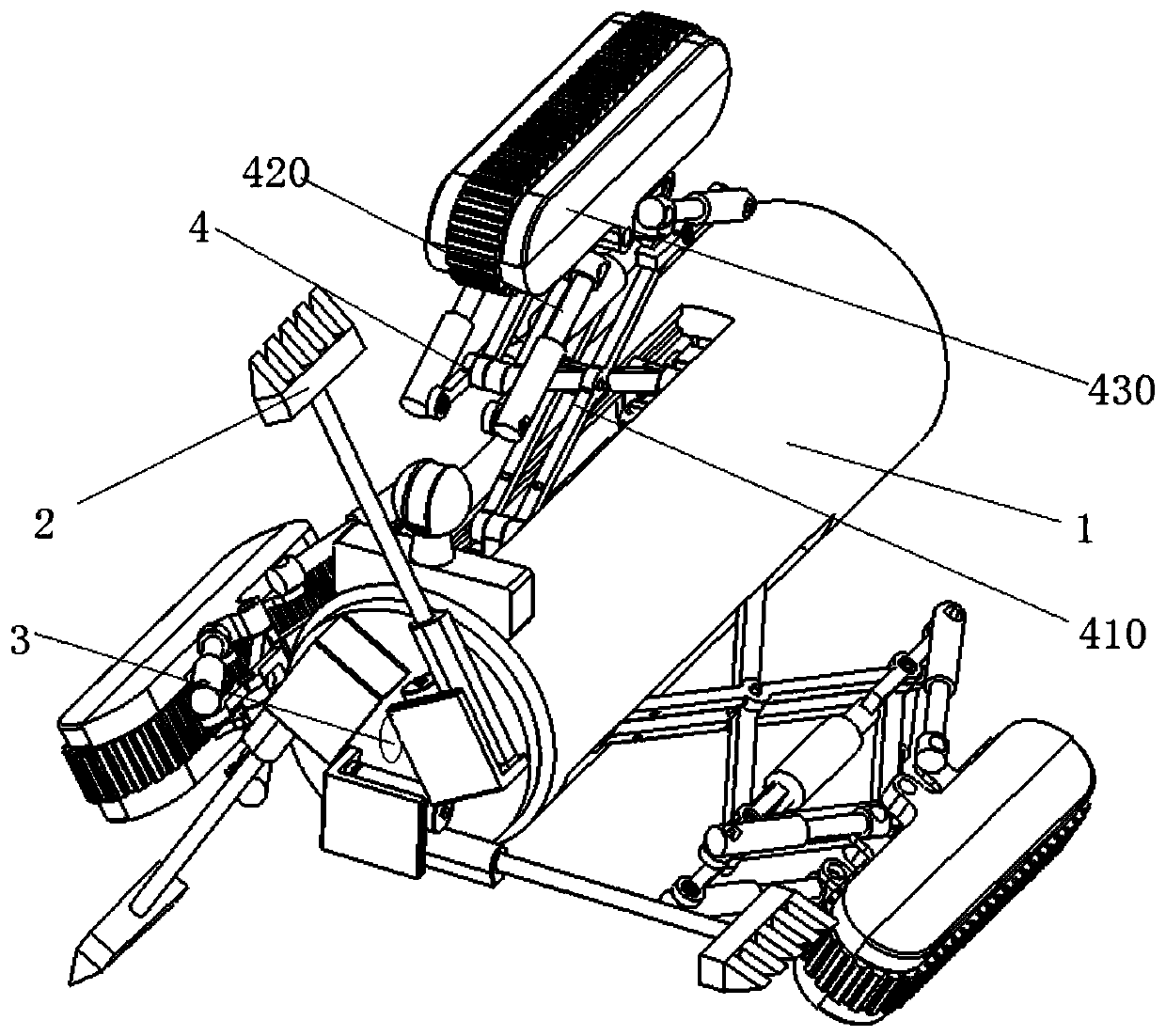

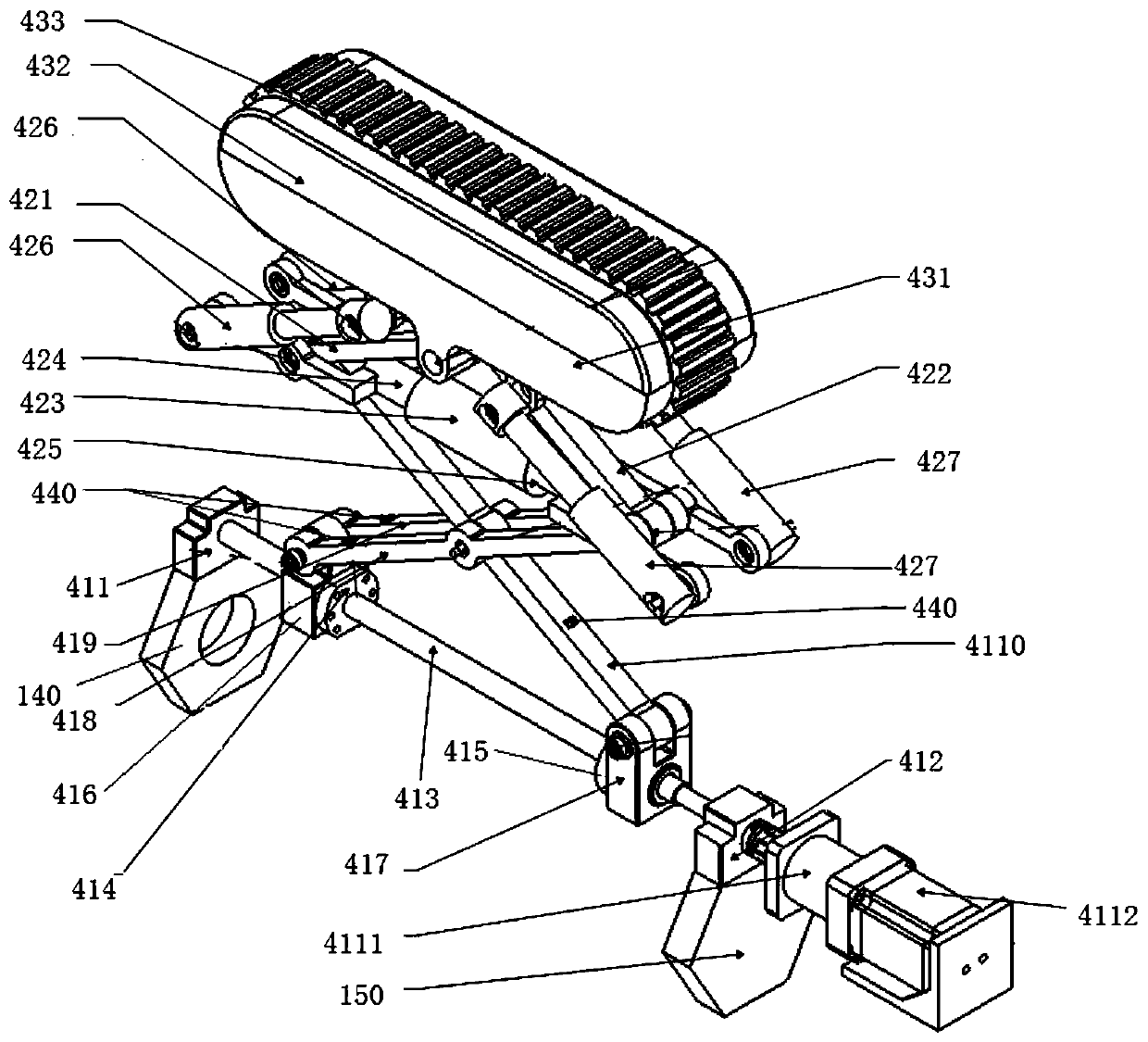

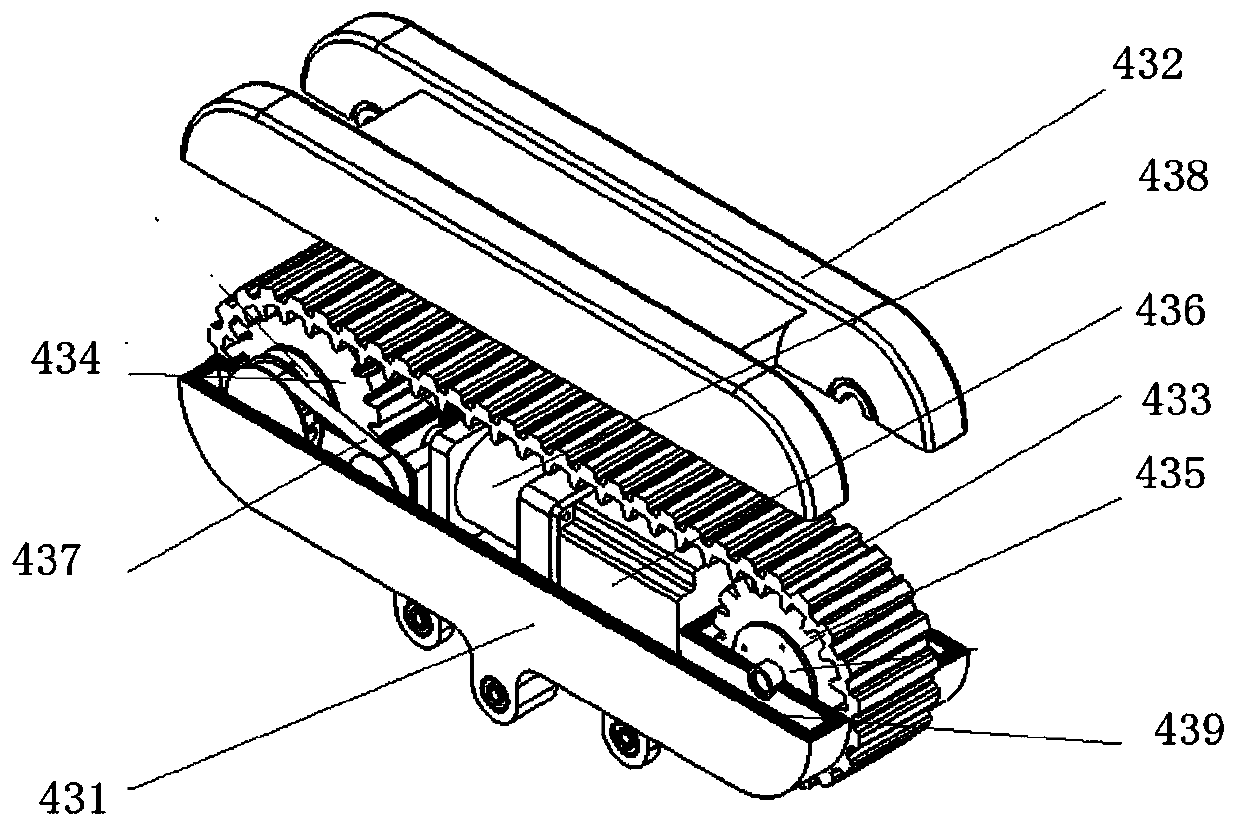

Self-adaption pipeline dredging robot

The invention relates to a self-adaption pipeline dredging robot. The self-adaption pipeline dredging robot comprises a shell, a reamer dredging mechanism, a camera and a plurality of traveling devices. The reamer dredging mechanism is arranged on the shell. The camera is arranged on the shell. Each traveling device comprises a variable diameter mechanism, a traveling mechanism and a pressure sensing module. The variable diameter mechanisms are arranged on the shell. The traveling mechanisms are arranged at the output ends of the corresponding variable diameter mechanisms. The pressure sensingmodules are matched with the corresponding lifting type variable diameter mechanisms. The self-adaption pipeline dredging robot has the beneficial effects that the robot is charged downward into a pipeline, and internal images of the pipeline can be acquired in real time so that working staff can know the environment of the robot conveniently and adjust the robot in time; data are monitored through the pressure sensing modules, the force condition and working conditions of the robot can be known conveniently, and the variable diameter mechanisms can be adjusted in time; thus, the robot can adapt to different pipeline diameters and can be stabilized in the most effective working condition all the time.

Owner:WUHAN UNIV OF TECH

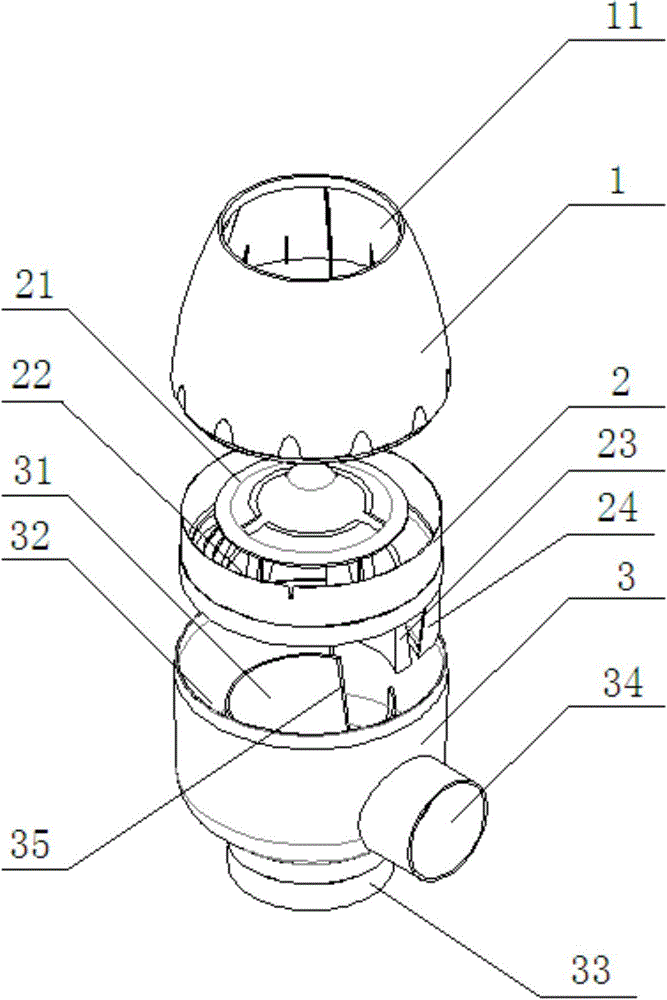

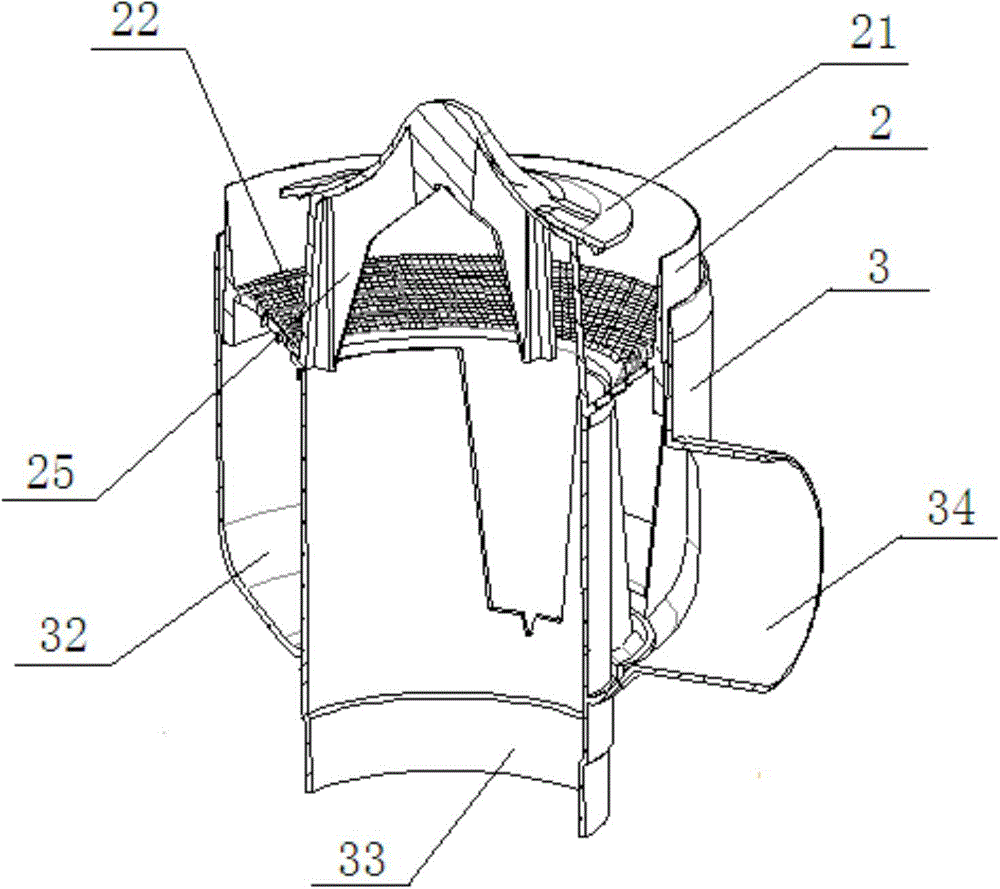

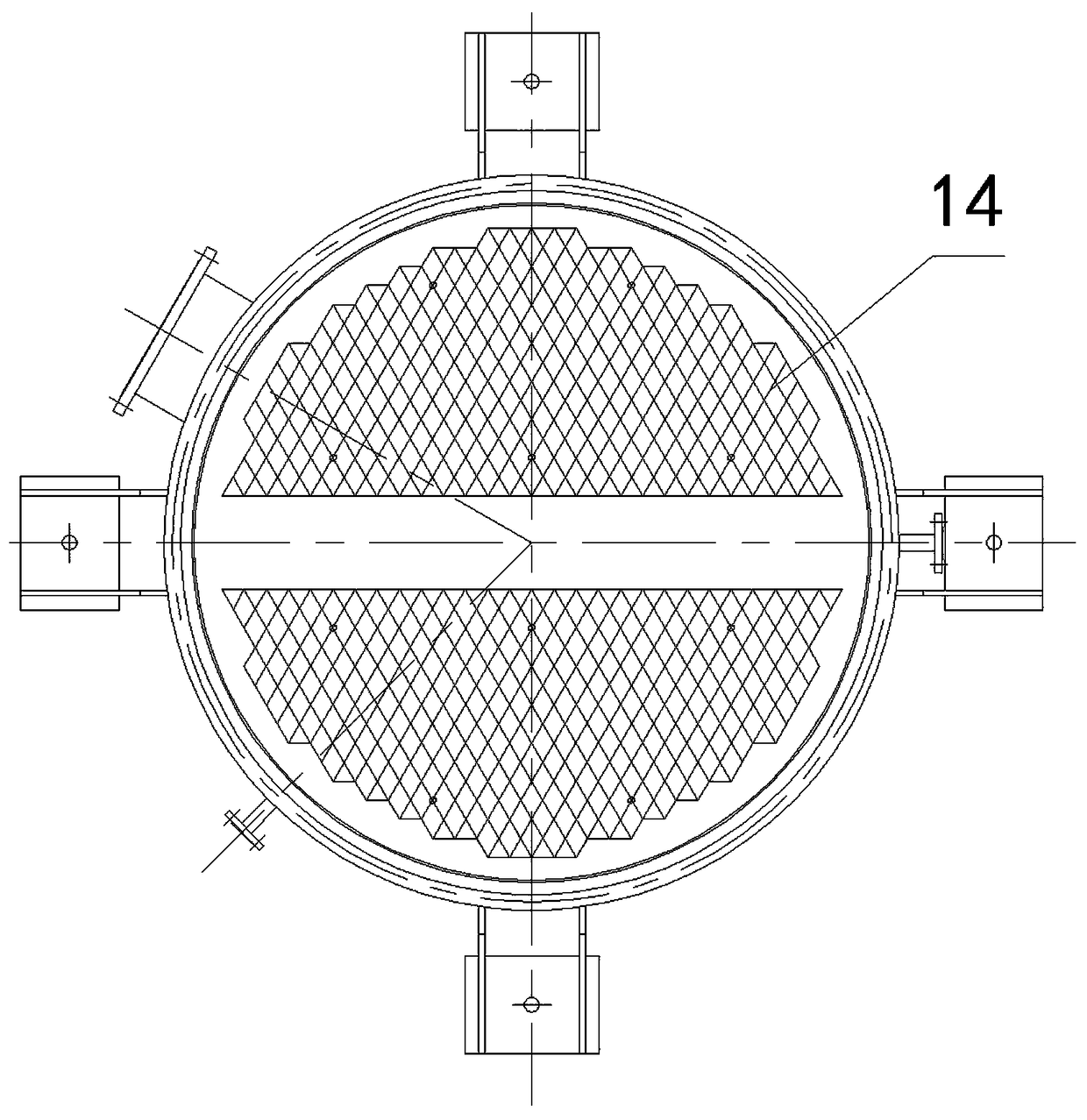

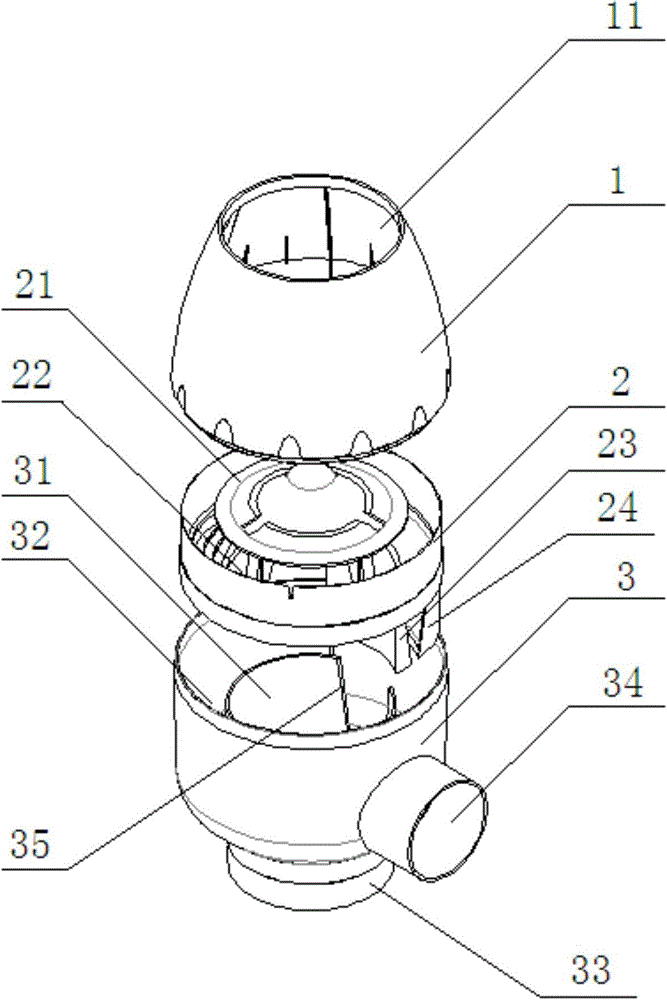

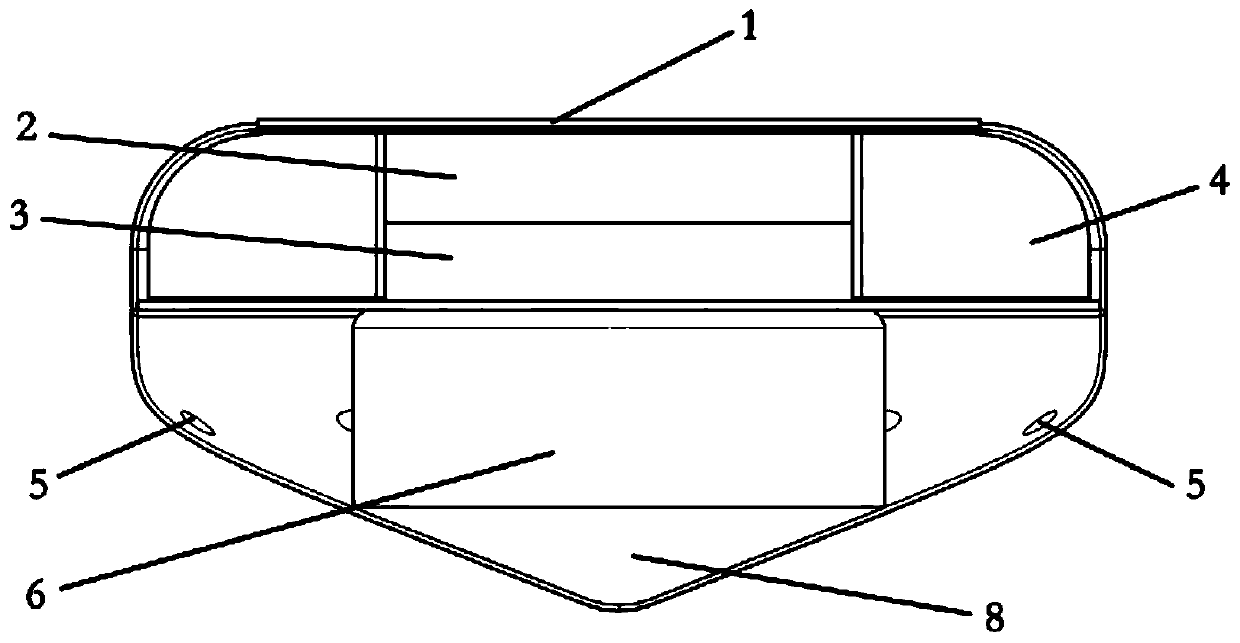

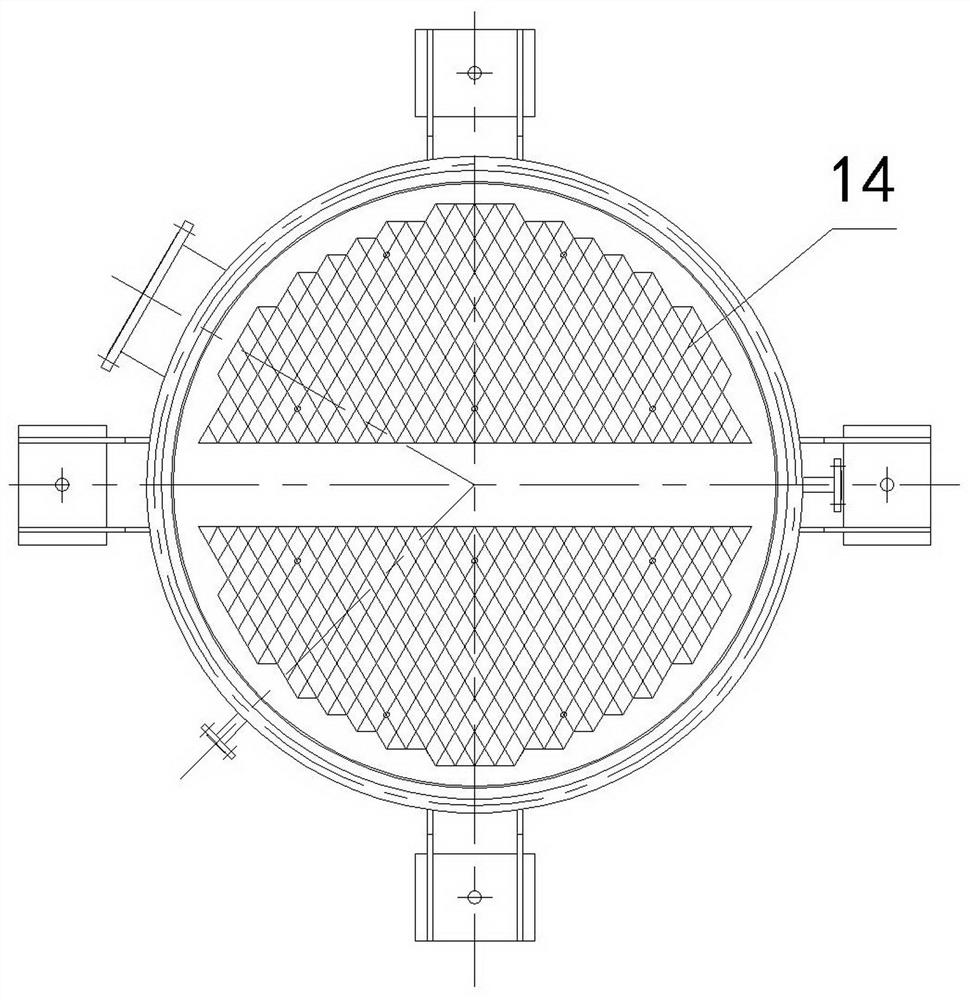

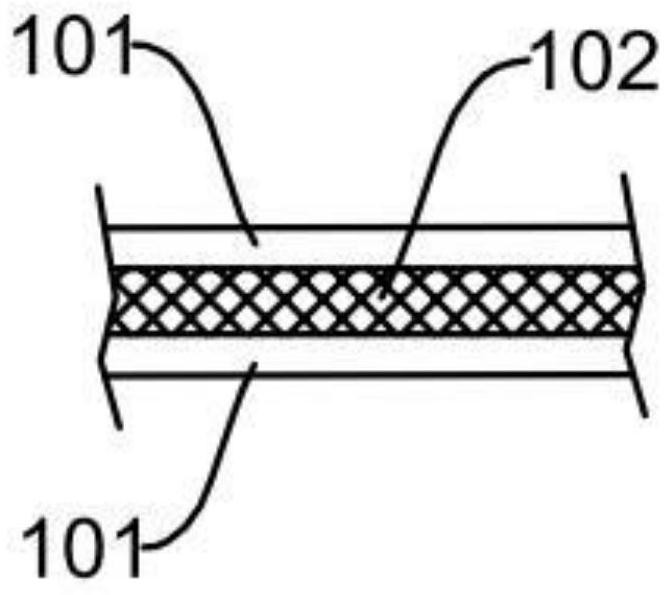

Rainwater filter

ActiveCN104436794AAvoid enteringAvoid harmStationary filtering element filtersRainwater harvestingEngineering

The invention provides a rainwater filter. The rainwater filter comprises a roughly elliptical shell, wherein the shell comprises an upper shell, a filter element and a lower shell which are sequentially sheathed; a rainwater collecting pipe connector is arranged at the upper part of the upper shell, a sundries exhaust port is arranged at the lower part of the lower shell, a purified water exhaust port is arranged on the side surface of the lower shell, a sundries collecting port communicated with the sundries exhaust port is arranged at the center of the lower shell, a purified water collecting chamber is formed by a space between the outer wall of the sundries collecting port and the lower shell, a water distributing plate is arranged at the center of the filter element, an annular filter screen is arranged below the water distributing plate, and the surface of the annular filter screen is gradually inclined downwards to an inner ring end surface from an outer ring end surface. The rainwater filter can automatically remove the sundries in rainwater and can rapidly exhaust the sundries, and has the characteristics of simple structure, skillful design and good filtering effect.

Owner:BEIJING TIDELION S&I RAINWATER HARVESTING TECH CO LTD

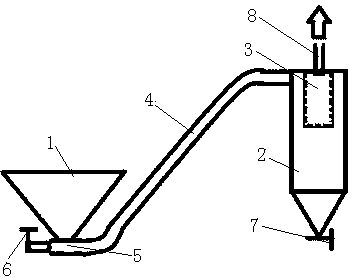

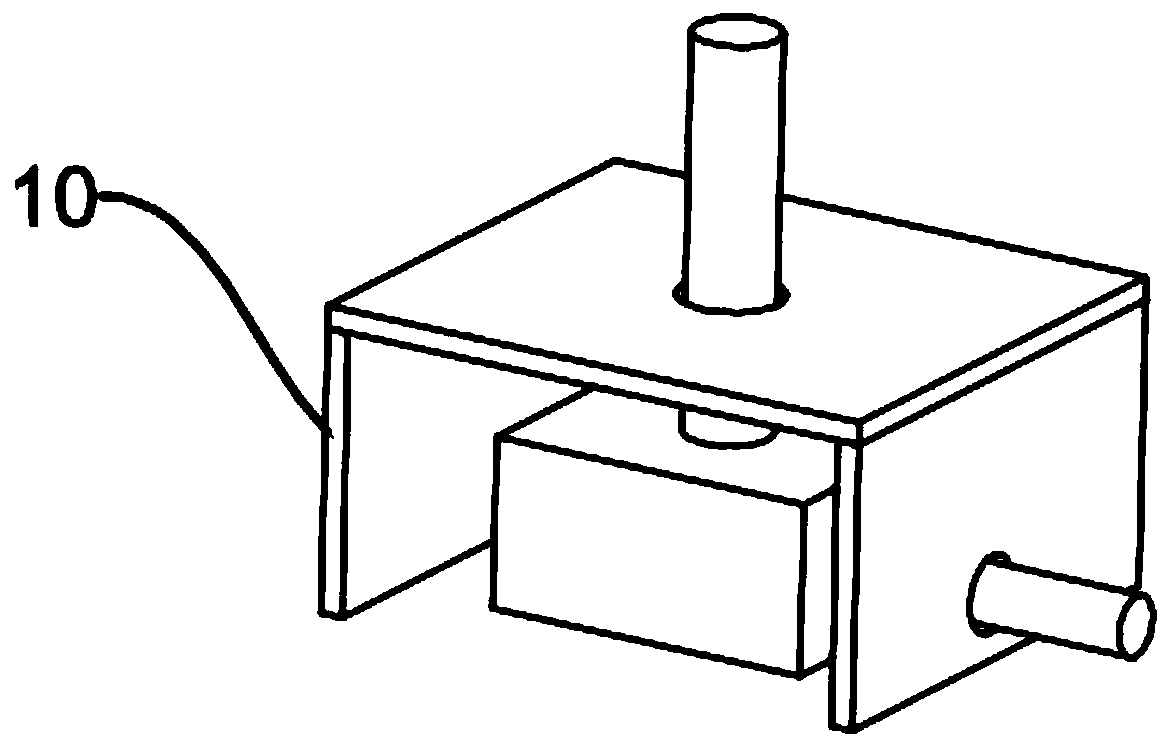

Vacuum material-sucking dust removal device

InactiveCN103449185AHigh airflow ratioImprove delivery efficiencyDispersed particle filtrationBulk conveyorsEngineeringFlow ratio

The invention relates to a vacuum material-sucking dust removal device. The vacuum material-sucking dust removal device comprises a hopper, a material sucking pipe is arranged on the lower portion of the hopper, one end of the material sucking pipe is connected to an air inlet device, and the other end of the material sucking pipe is connected to a storage tank. A filter is arranged in the storage tank, the upper portion of the storage tank is provided with a vacuum suction port, and the lower portion of the suction port is provided with a material discharging port. According to the vacuum material-sucking dust removal device, material is sucked by the principle of vacuum material suction, high material air flow ratio can be acquired, conveying efficiency is improved, and flowing speed of the material is controlled by controlling the air flow through an air inlet; a vacuum filter is arranged in a material bin, so that secondary contamination caused by using a dust remover additionally can be eliminated; meanwhile, the filter is arranged in the storage tank, dusts and other small objects in the tank can be removed, the vacuum suction port is prevented from blocking due to the entered dusts and other small objects, and the entire device is guaranteed to be in stable and effective operating state for a long time.

Owner:YANGZHOU SANDELI CHEM

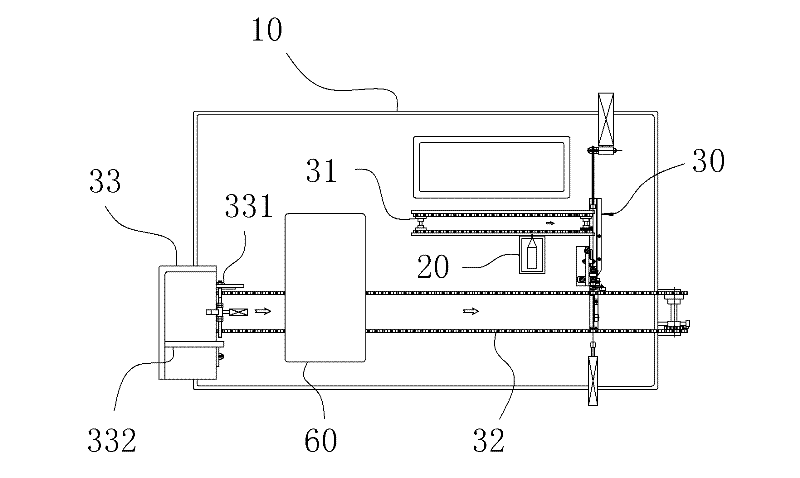

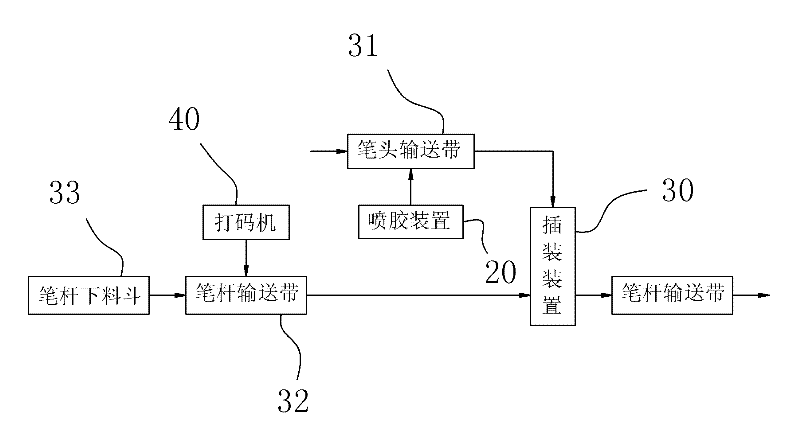

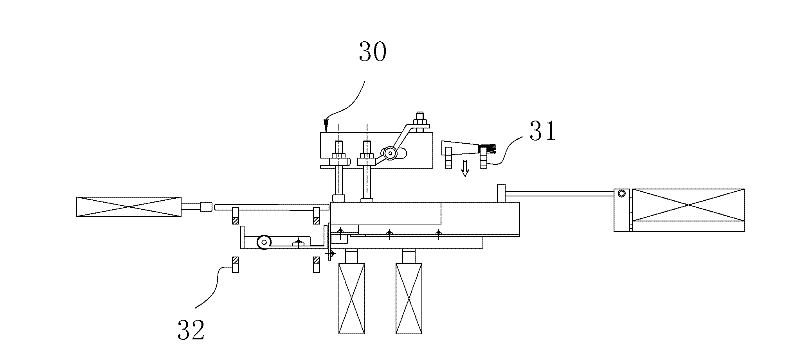

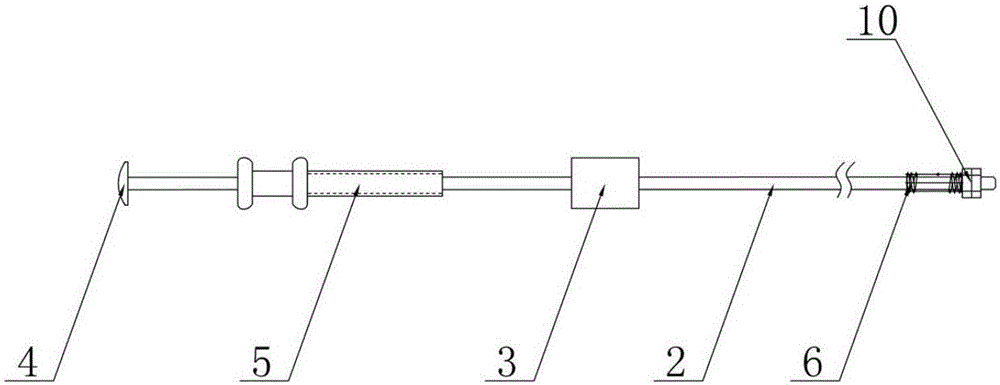

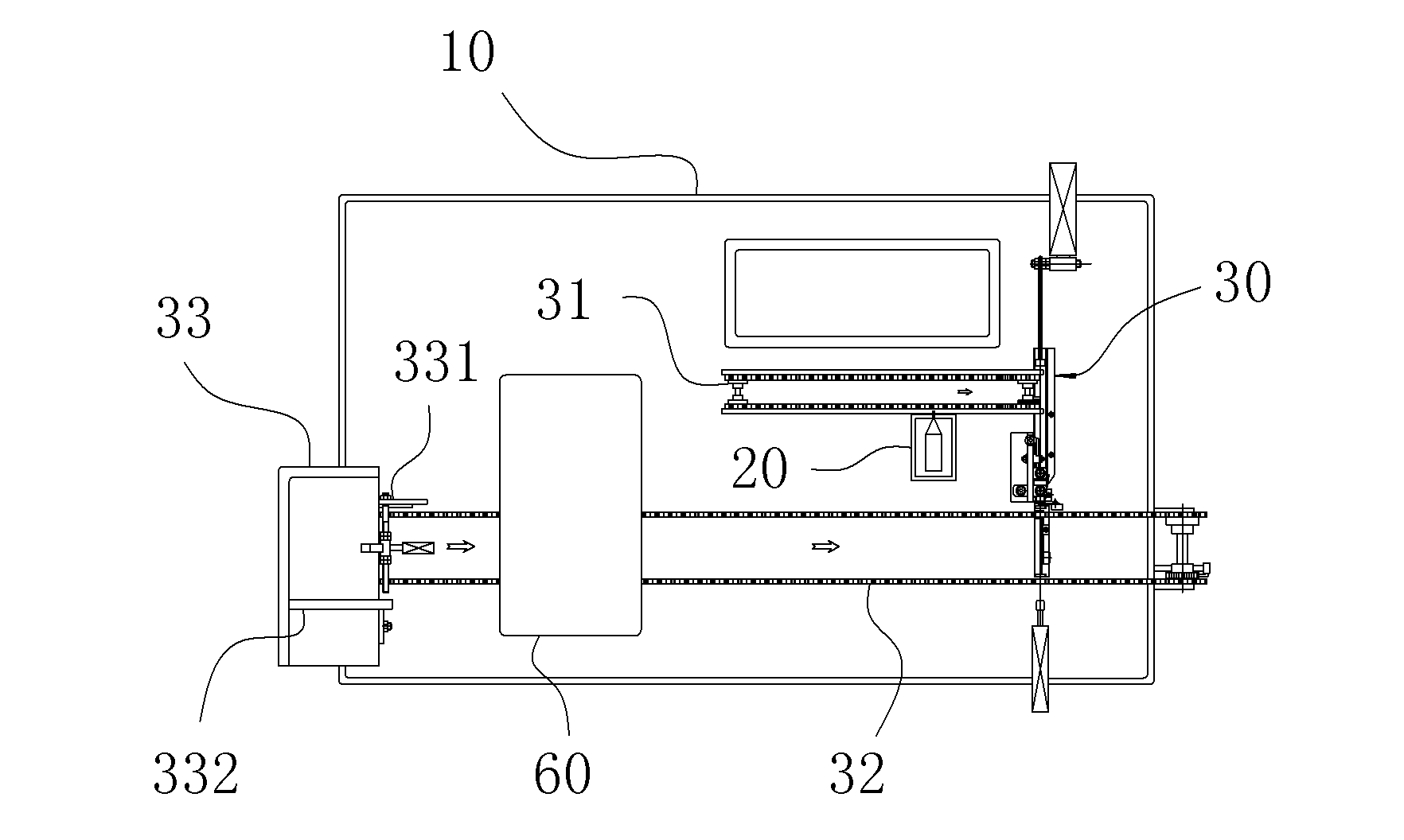

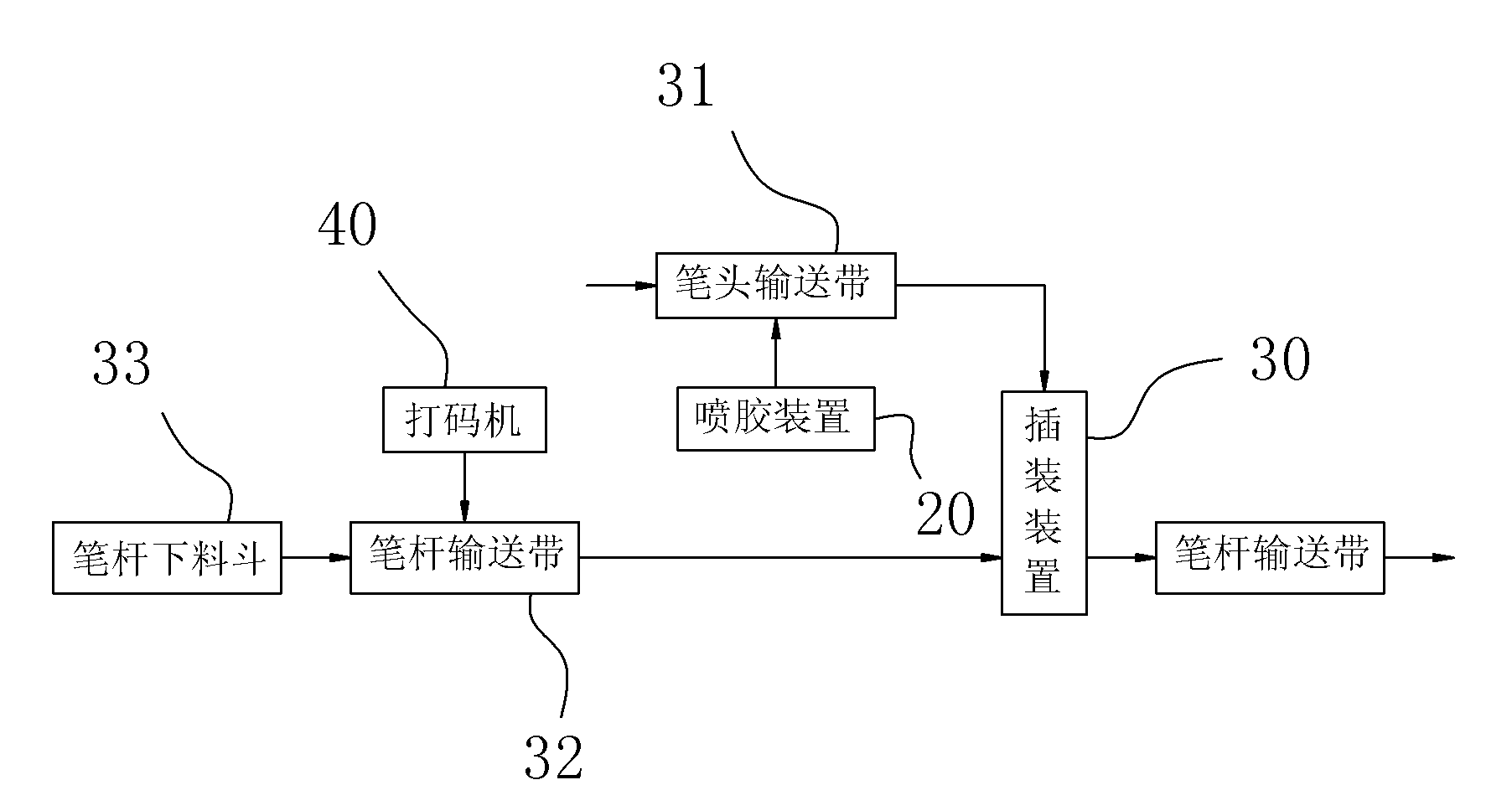

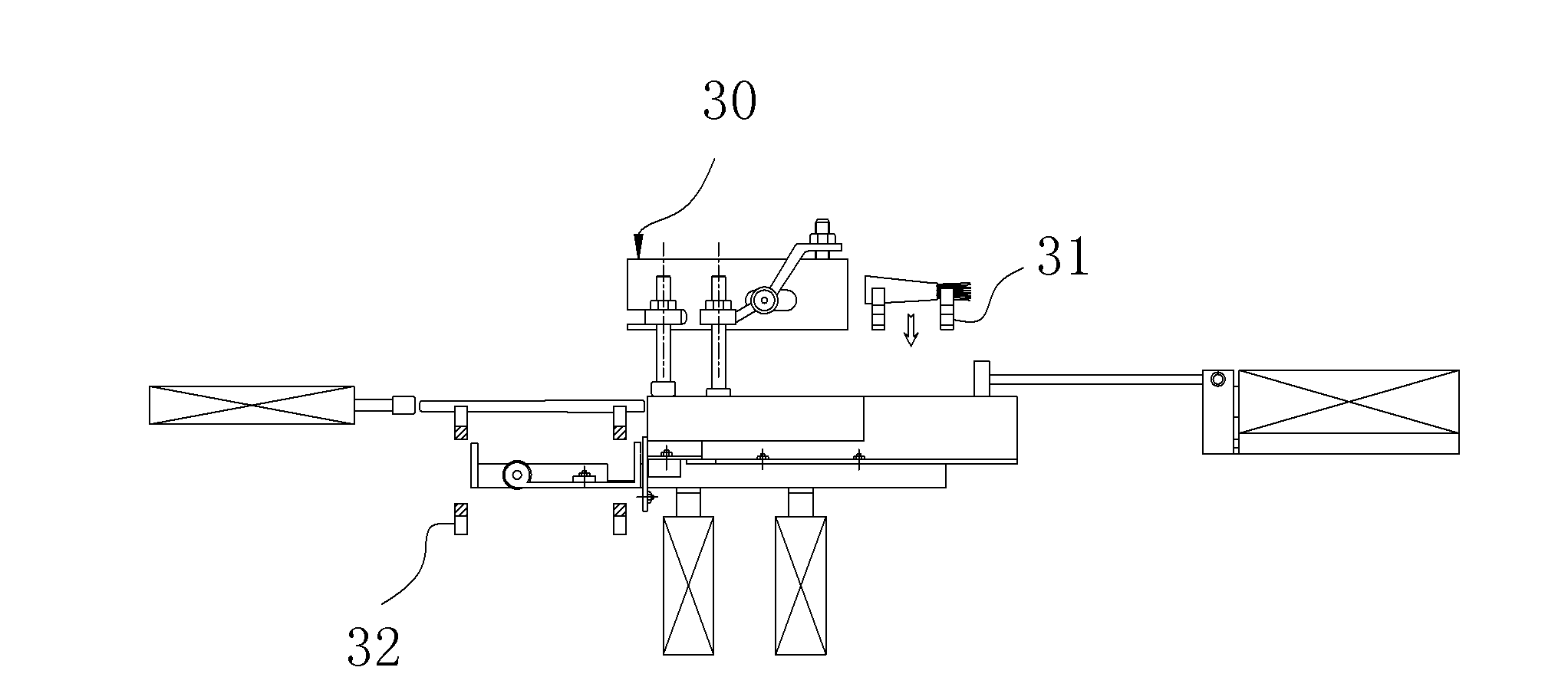

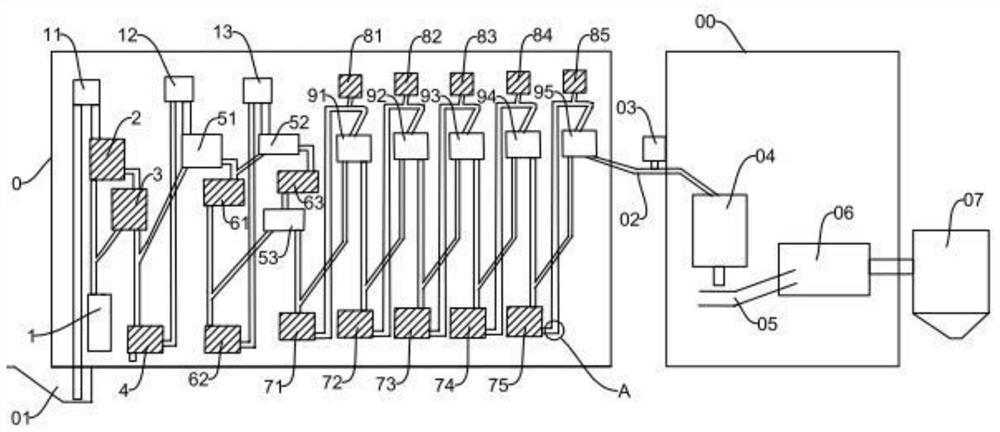

Pen making machine

Belonging to the pen making field, the invention specifically relates to a pen making machine. The machine of the invention comprises a frame which is provided with a nib glue spraying mechanism and a plug device for plugging of a nib and penholder. The plug device includes a nib conveying mechanism for conveying the nib to be plugged. The nib glue spraying mechanism is installed on the lateral of the nib conveying mechanism. And the glue spraying nozzle directs the inside of a cavity of the nib that is to be plugged and located on the nib conveying mechanism, so that a rapid and effective connection of the nib glue spraying process and the nib and penholder plugging process can be realized. While the plugging and assembling efficiency of the nib and penholder is improved, meanwhile, the assembling quality and product yield are also guaranteed. The machine can operate stably and reliably.

Owner:卫青山

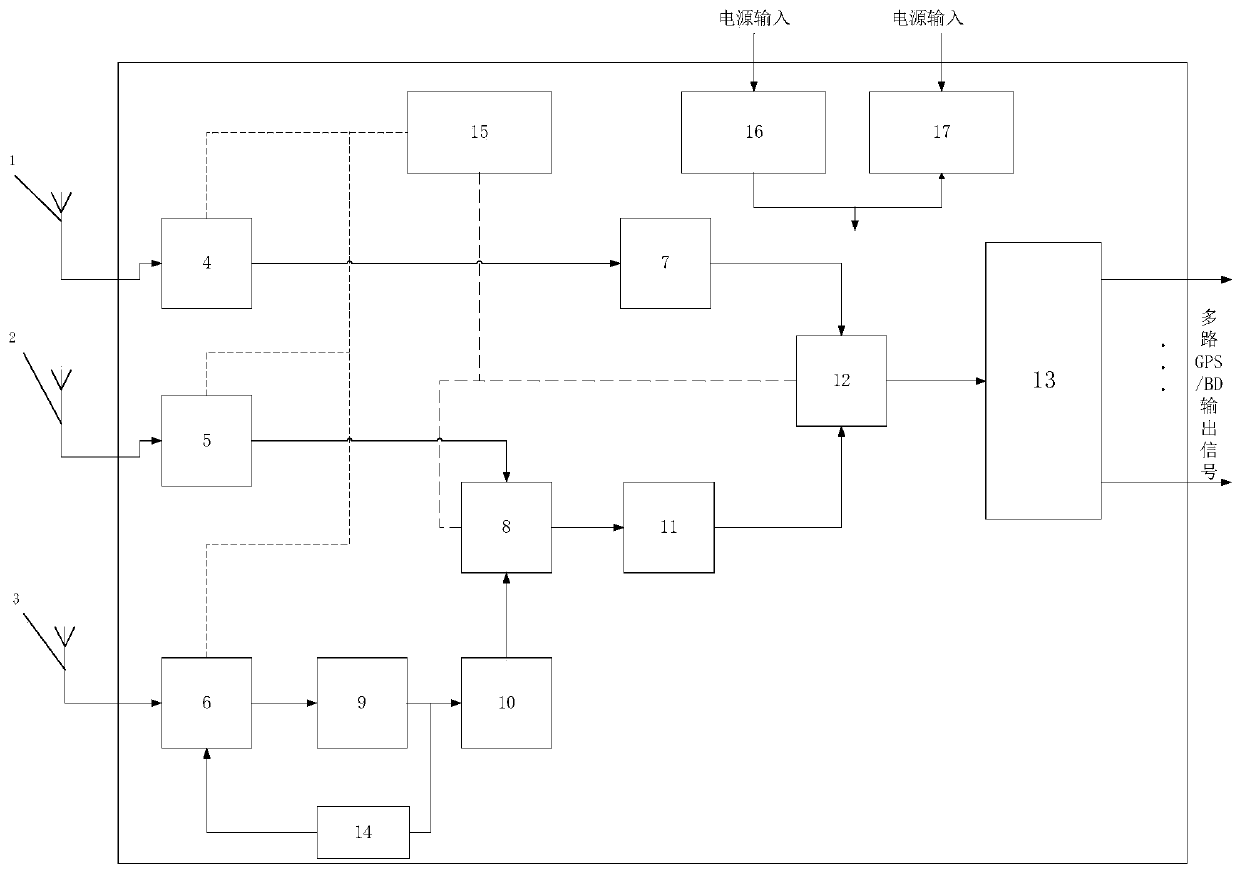

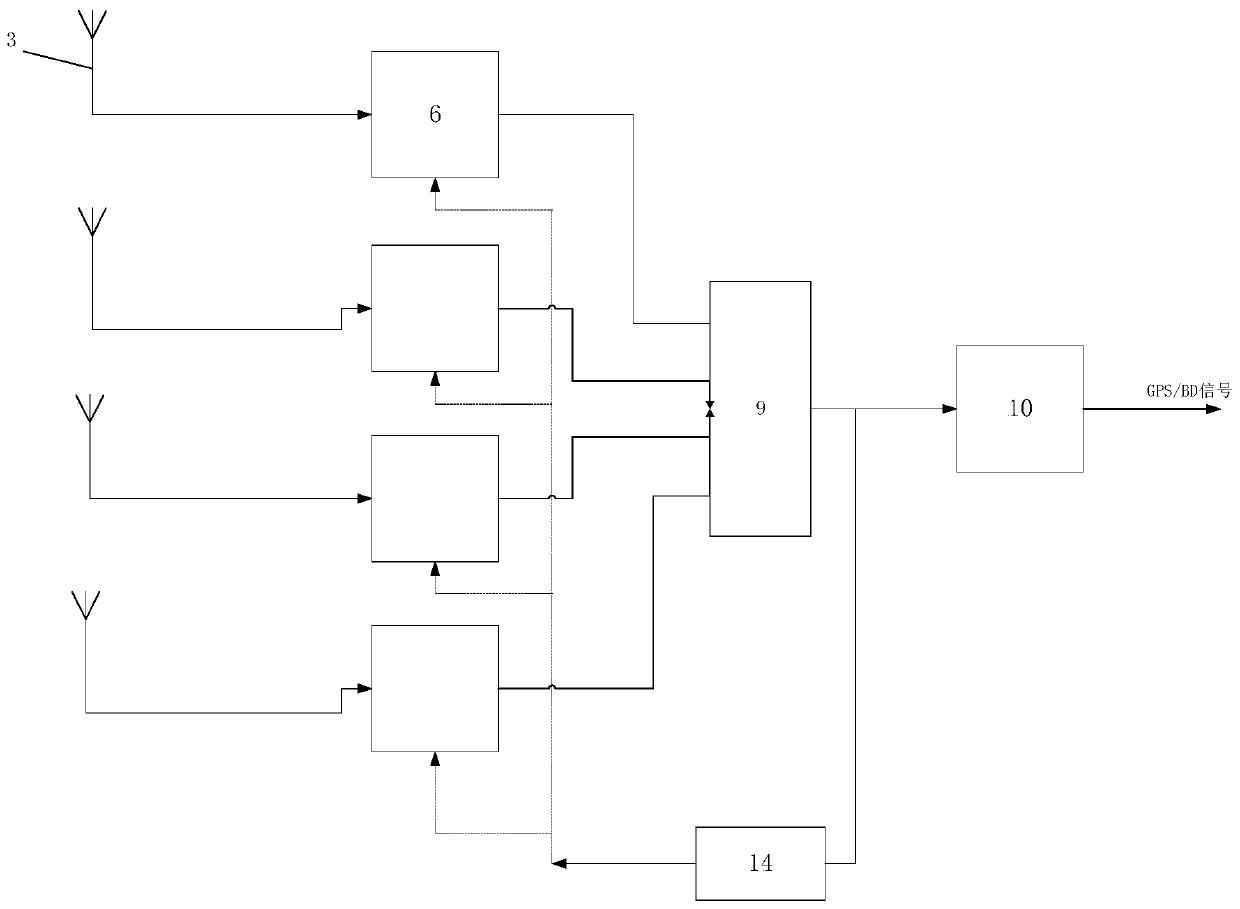

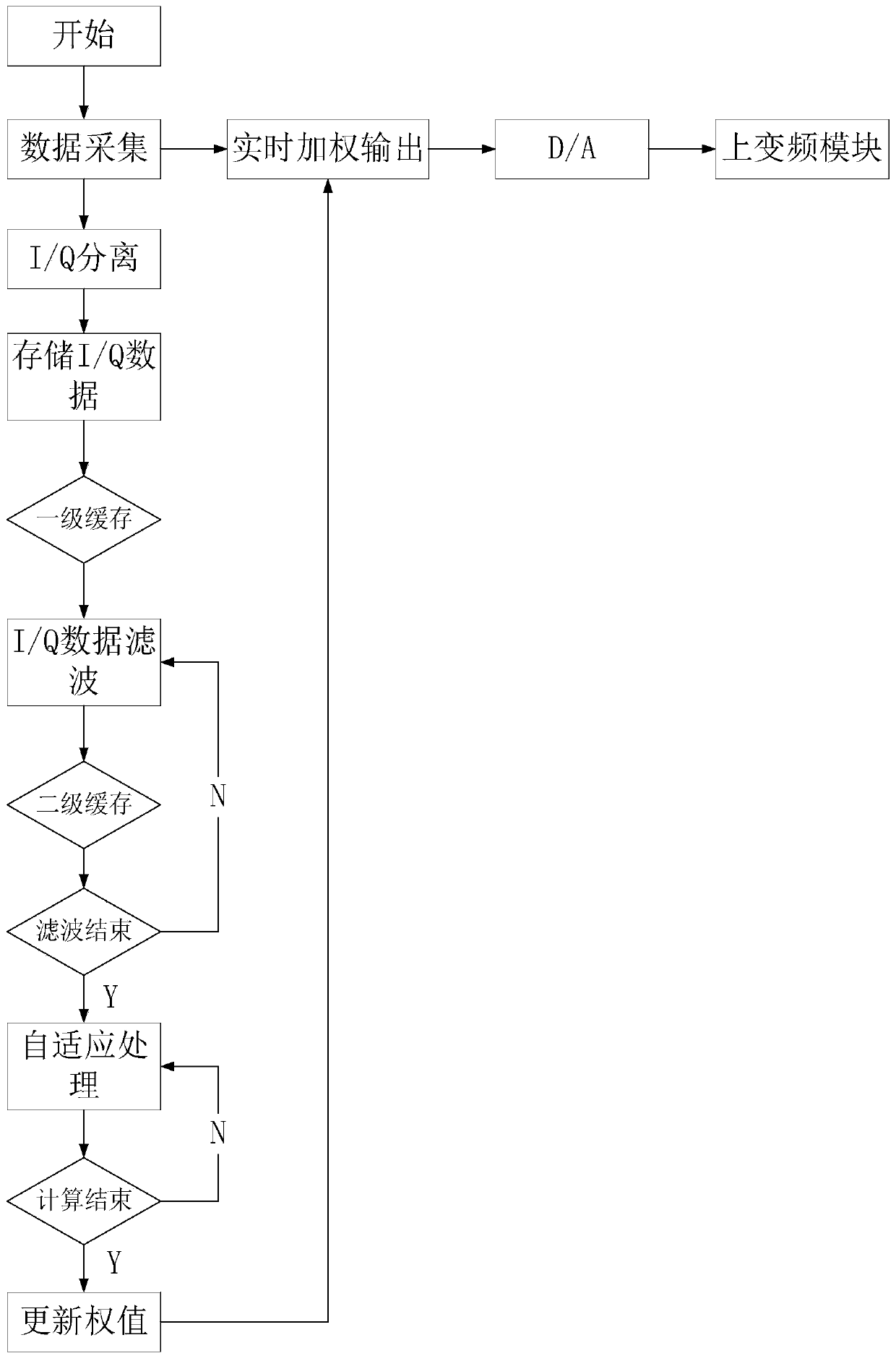

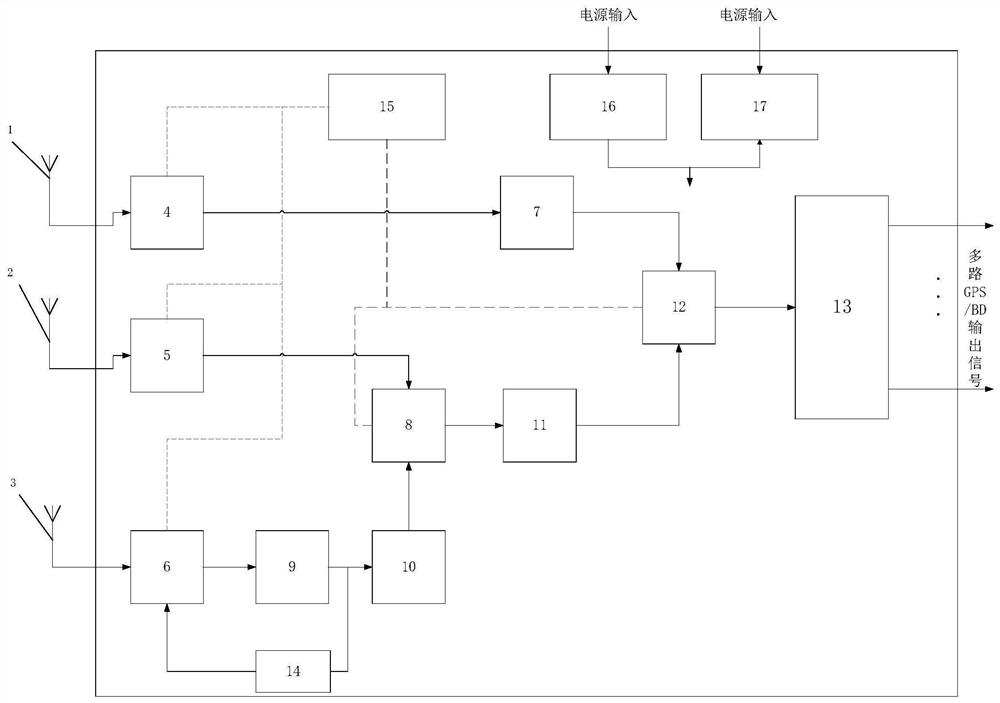

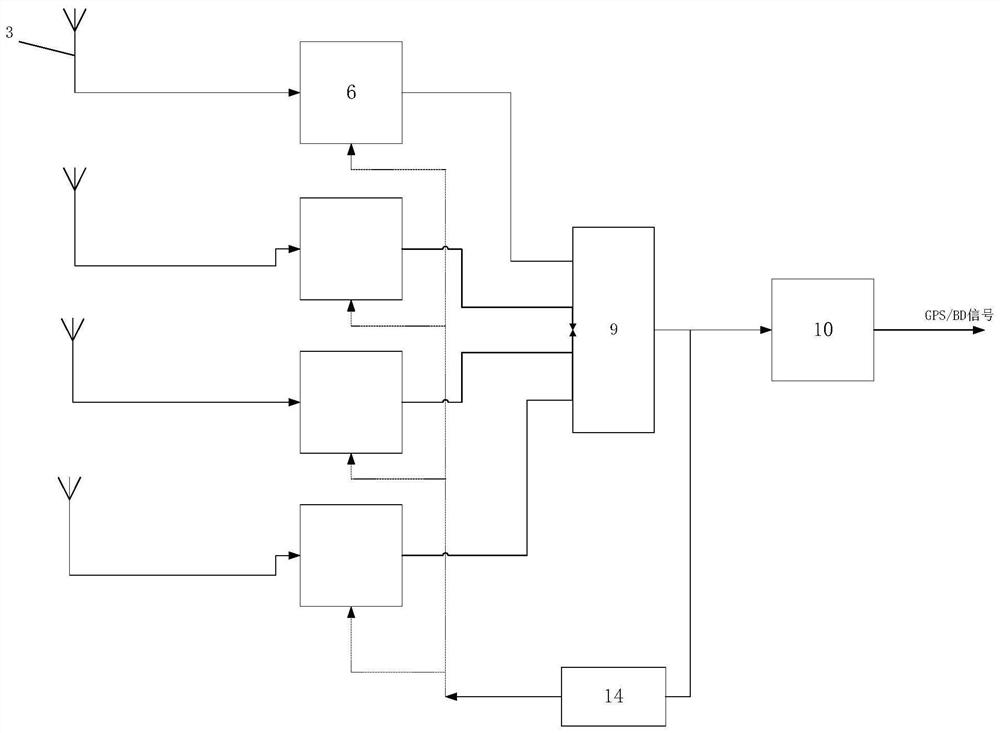

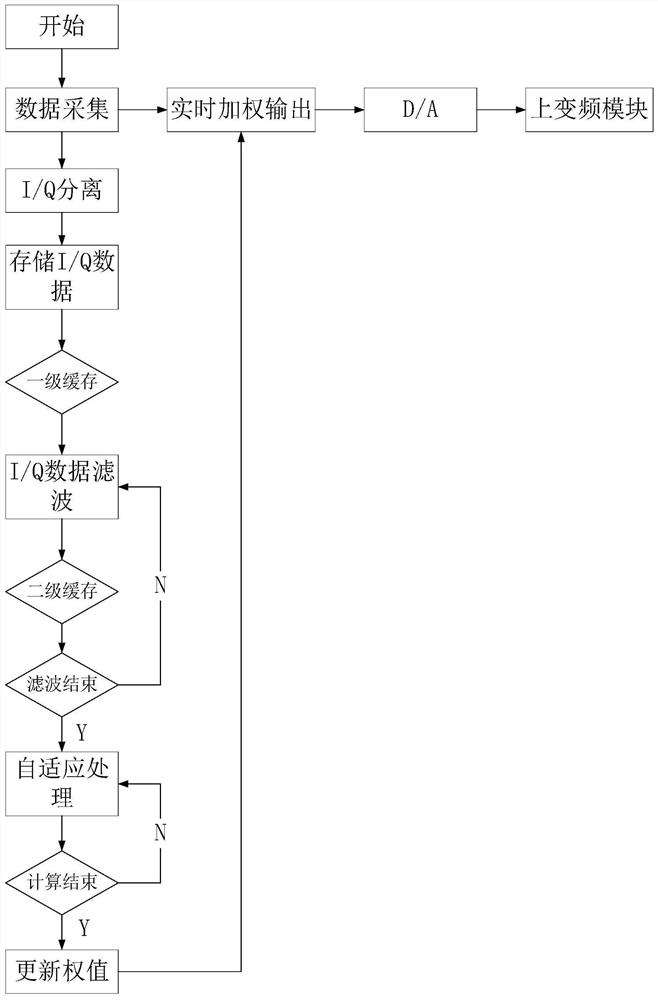

Dual-mode amplification multi-path distribution system with anti-interference function and distribution method

ActiveCN111505674AReduce in quantityReduce construction difficultySatellite radio beaconingInterference resistanceControl cell

The invention discloses a dual-mode amplification multi-path distribution system with an anti-interference function and a distribution method. According to the invention, the system is provided with three GPS / Beidou antenna units; a detection and control unit is used for detecting the signal intensity of a first radio frequency active unit, a second radio frequency active unit and a third radio frequency active unit, and controlling the switching between a radio frequency switch and a multi-channel GPS / Beidou signal switching unit; the third GPS / Beidou antenna unit is connected with an anti-interference module, GPS / Beidou signals can be continuously output when other antenna units are interfered and cannot work, the antenna has three-channel input and multi-channel output, the number of antenna feeder systems is effectively reduced, and the construction difficulty and cost are reduced.

Owner:SHAANXI TIANJI COMM TECH

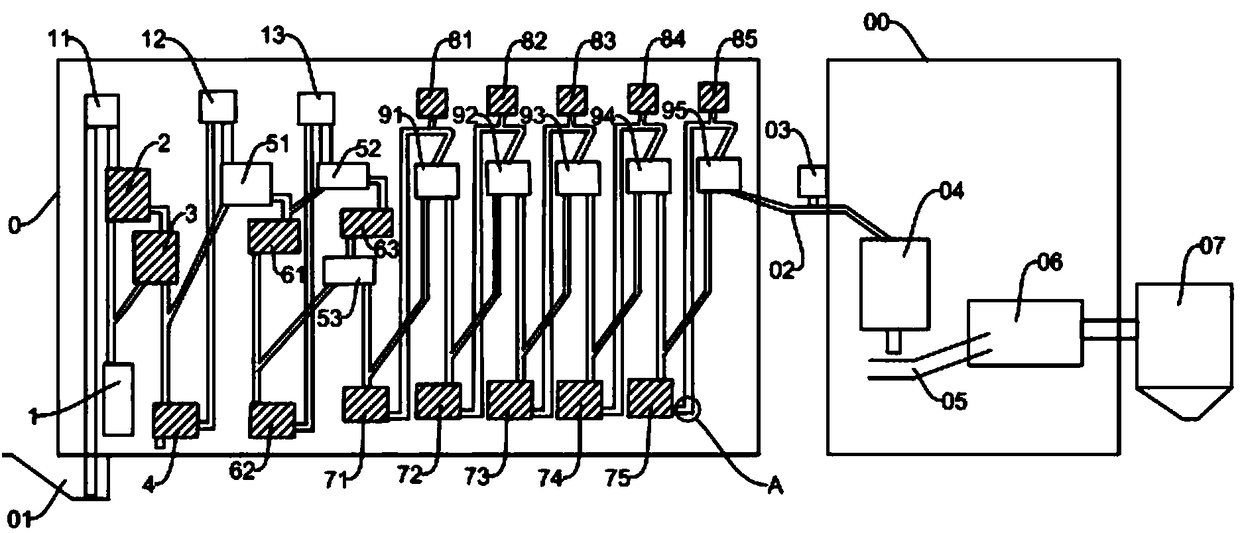

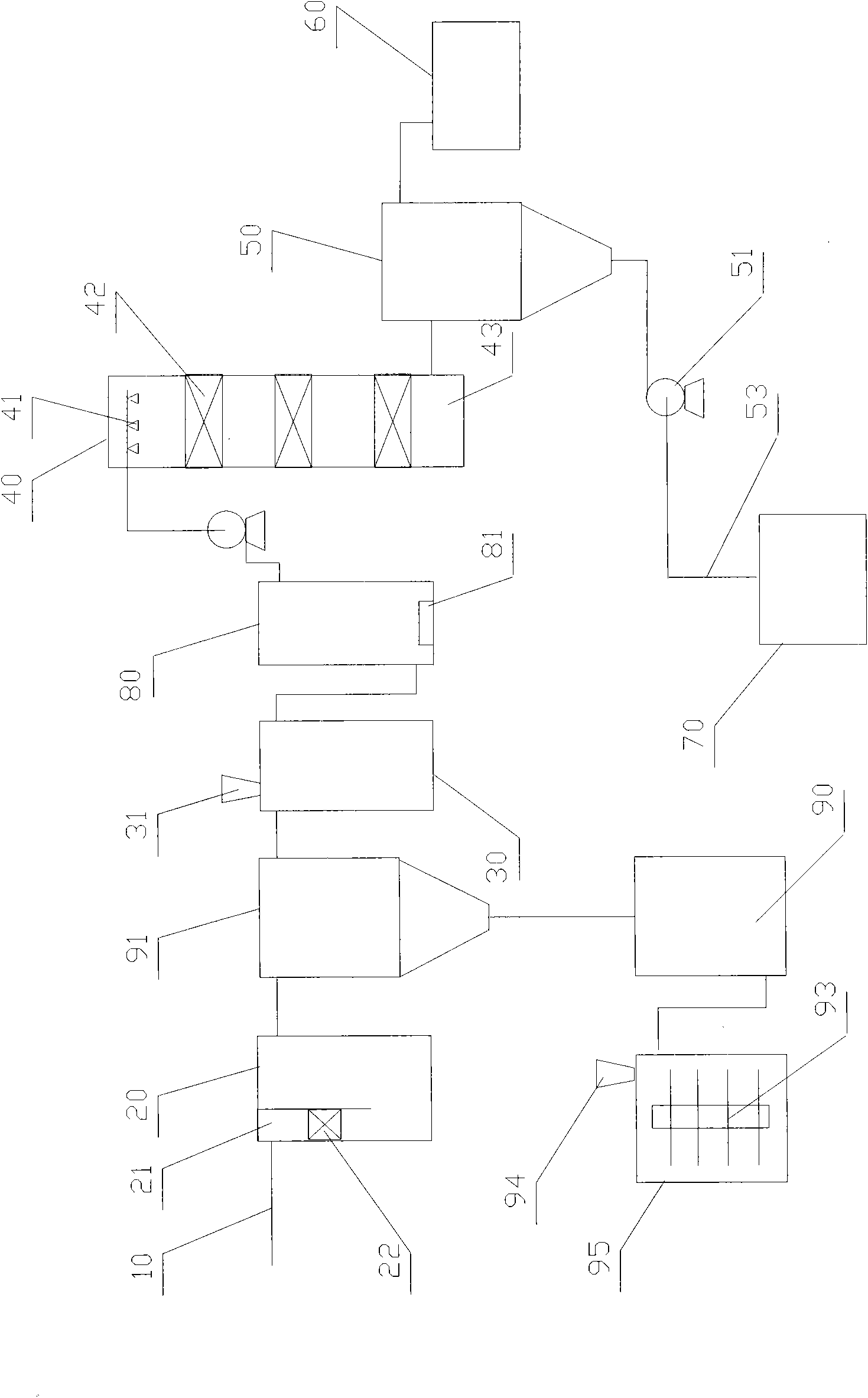

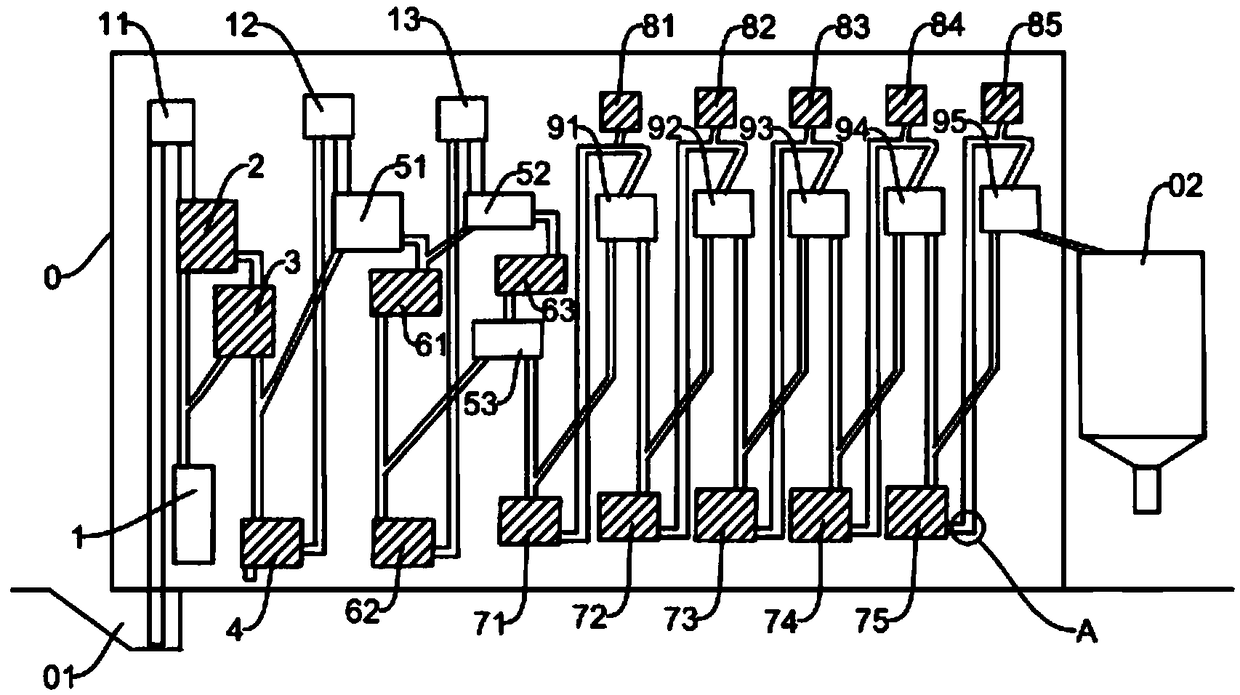

Efficient-type corn niblet powder-making and caking-making system and corn cake preparing method

ActiveCN108283956AReduce impurityGuaranteed finenessGrain huskingGrain polishingMulti linkMagnetic separator

Disclosed are an efficient-type corn niblet powder-making and caking-making system and a corn cake preparing method. The efficient-type corn niblet powder-making and caking-making system comprises a winnowing machine, a magnetic separator, a crushing and skinning machine, a crushing mechanism and a milling mechanism which are arranged in a treatment workshop, further comprises a batching tank anda puffing machine which are arranged in a puffing workshop, and further comprises a feeding channel and a finished product temporary storage tank. The feeding channel is formed in a downward-inclinedmode from the position, located on the outer side of the treatment workshop, of the ground, extends into the treatment workshop, and is connected with the bottom end of a first elevator in the treatment workshop. The refining effect is achieved through multi-link screening and then conveying and a multi-stage grinding and screening mechanism, so that feeding, powder-making, puffing and dischargingare conducted in different workshops, feeding and discharging are convenient to operate, the situation that operators are in the treatment workshop with loud noise is avoided, mutual interference ofpowder-making and puffing processes is avoided, noise reduction treatment is further conducted on key equipment, air pipes and an elevator channel, and the structure of the connecting position of theair pipes is improved to solve the situation of outage retention.

Owner:成都昌盛鸿笙食品有限公司

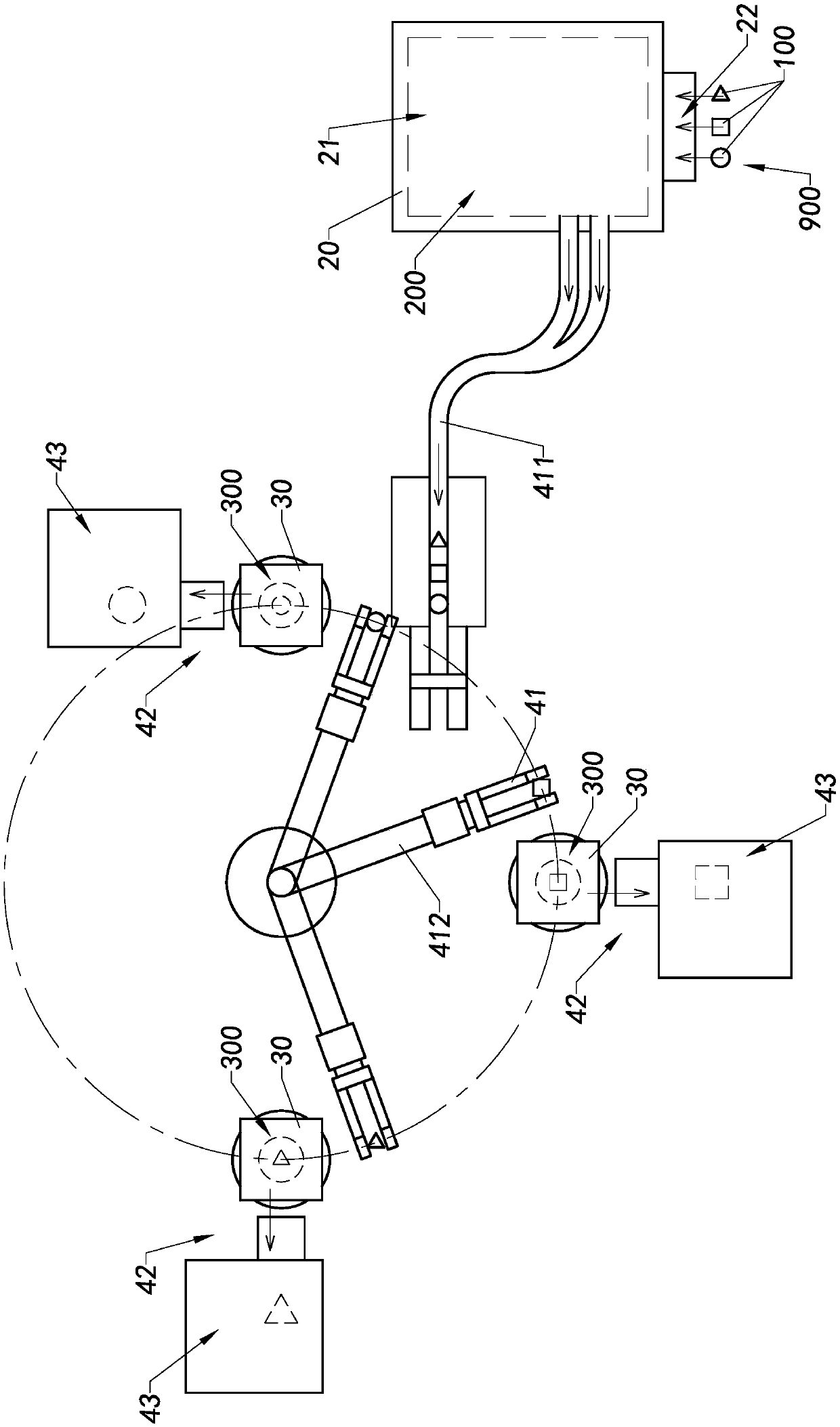

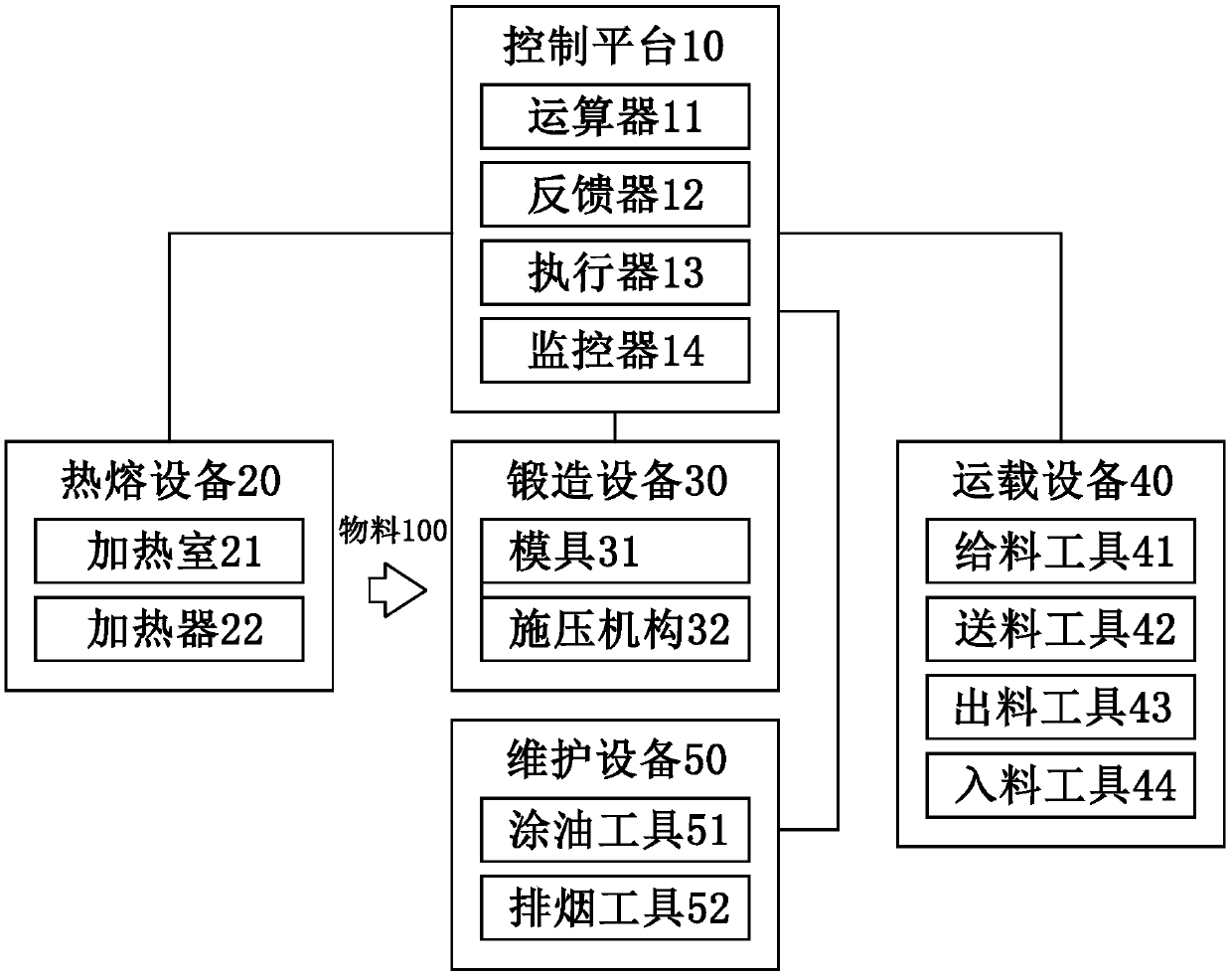

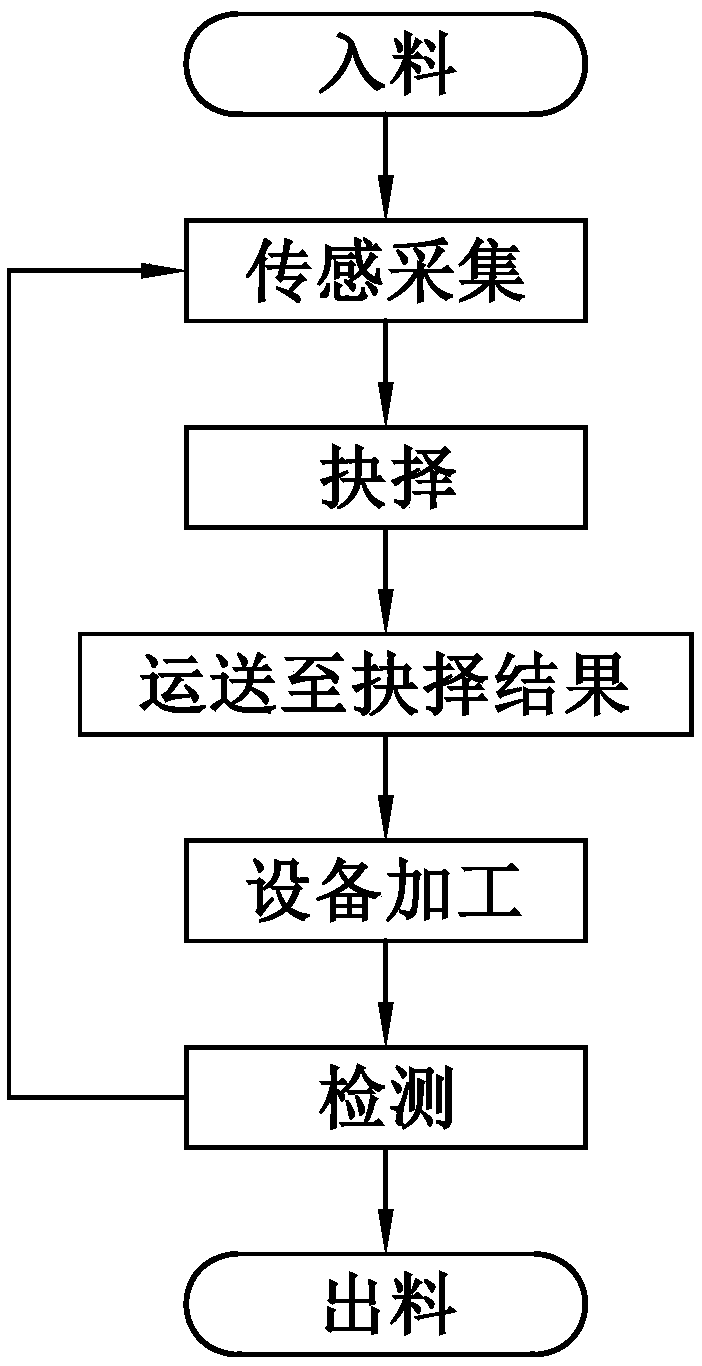

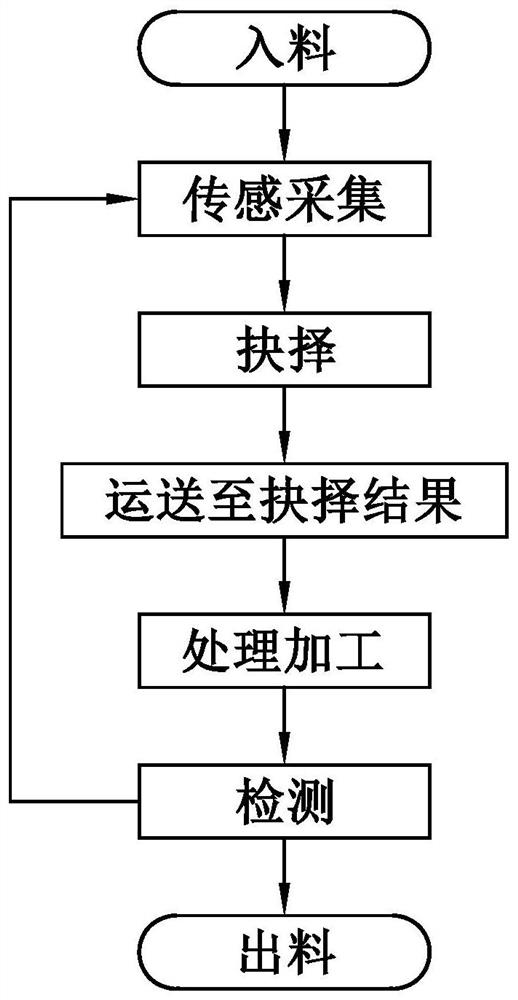

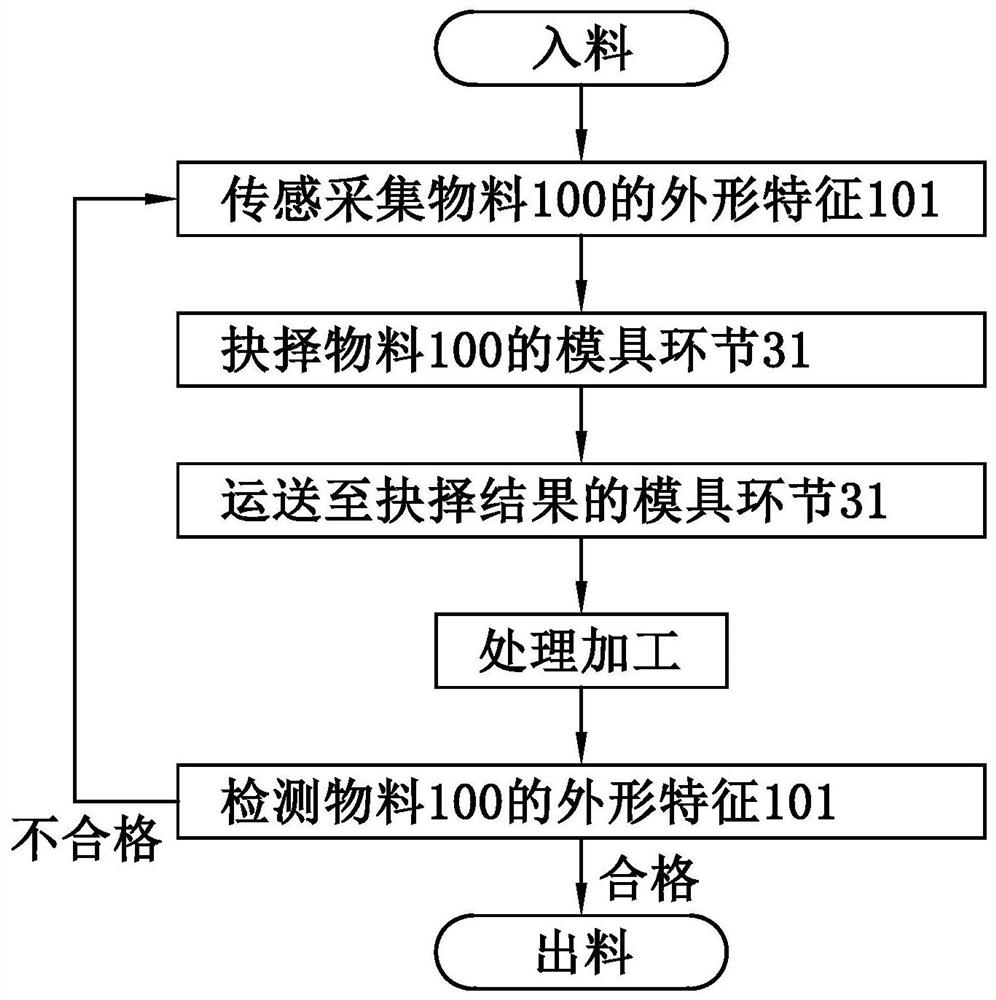

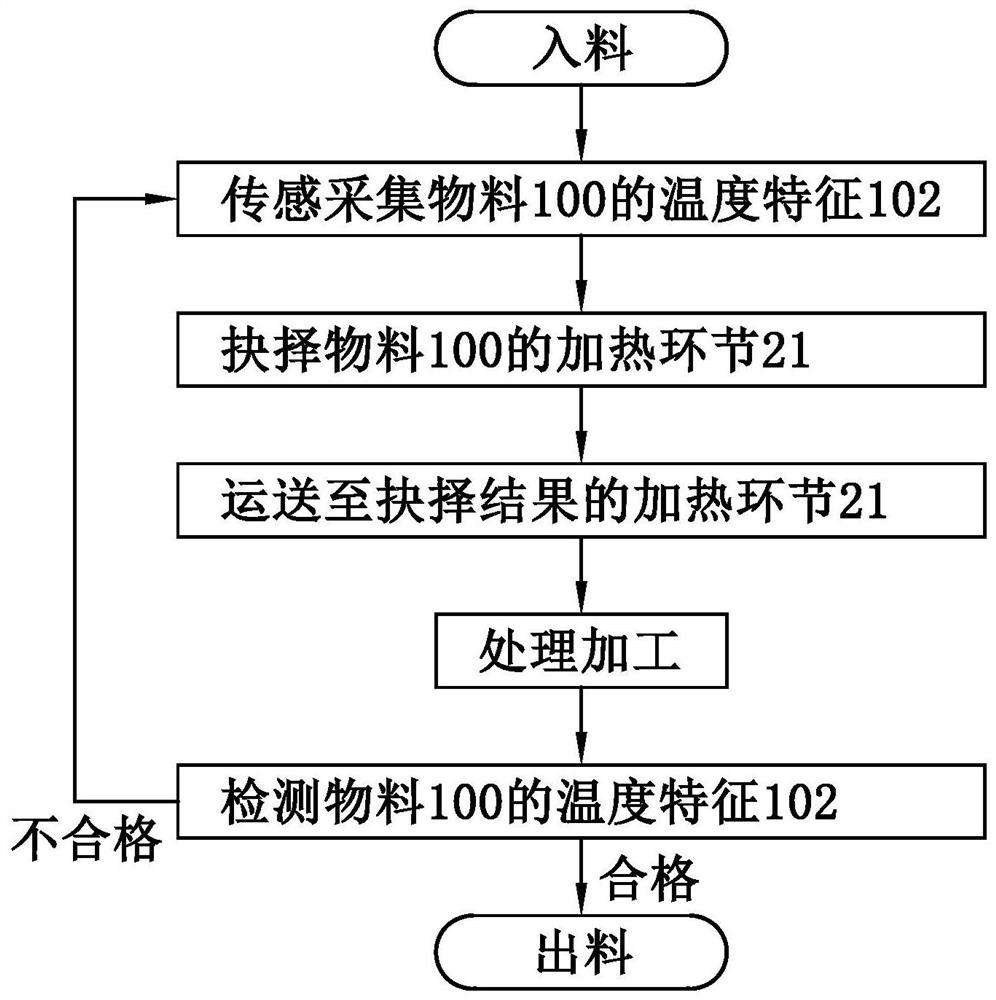

Forging and pressing production method

ActiveCN110026513ANo manual operationLow costForging press drivesHandling devicesManufactured materialHot melt

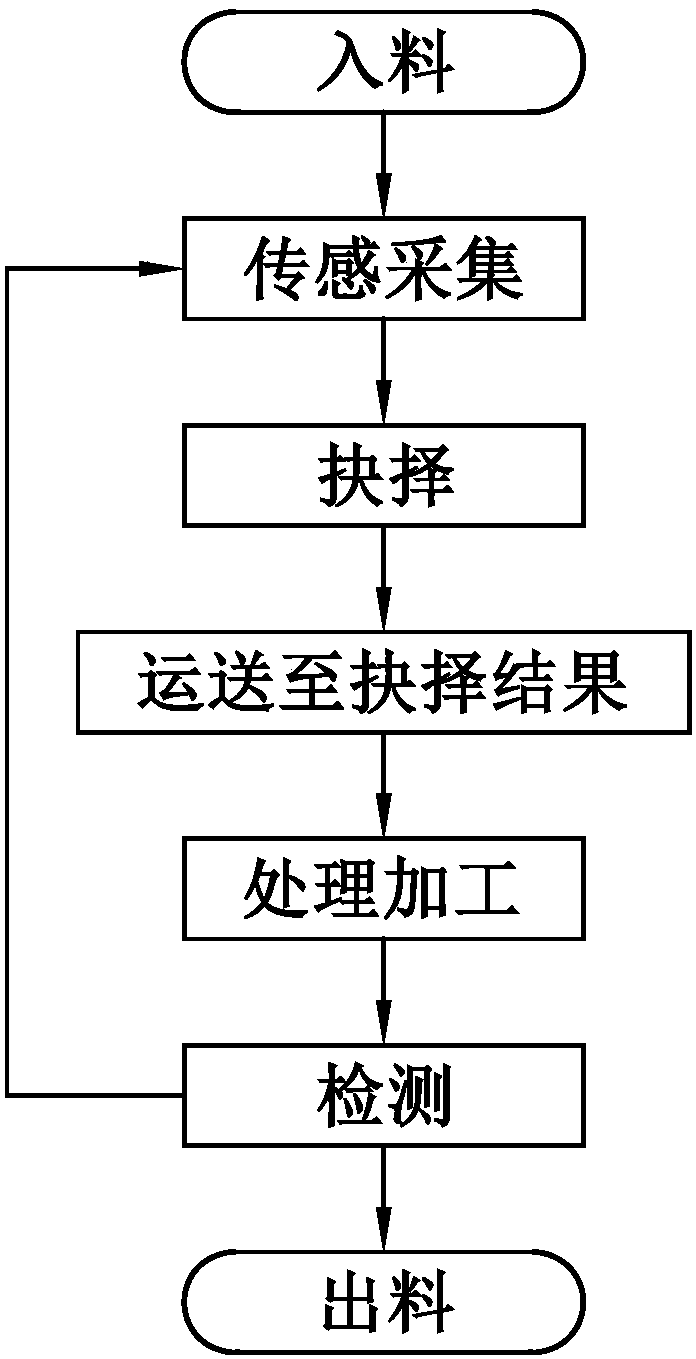

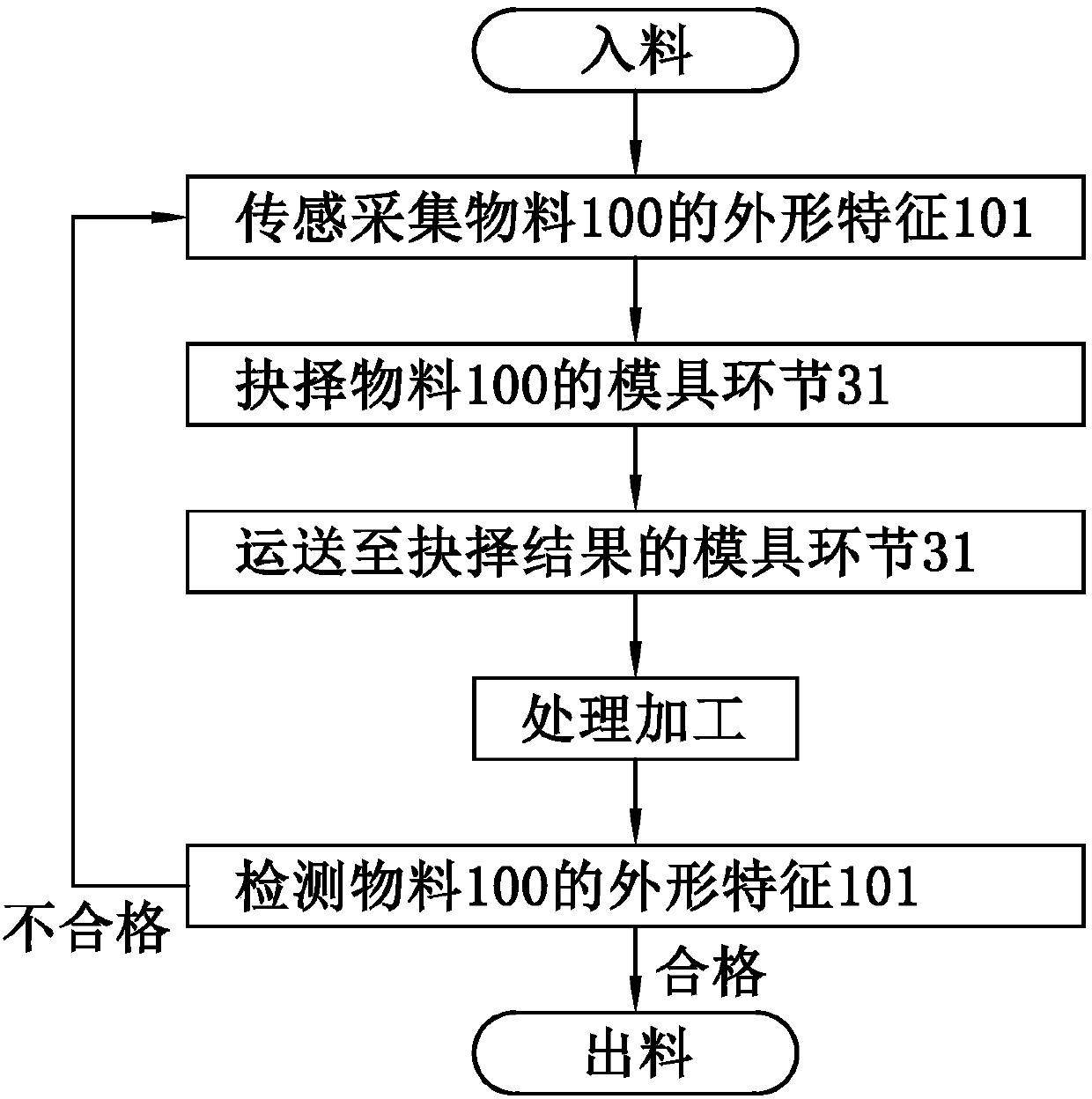

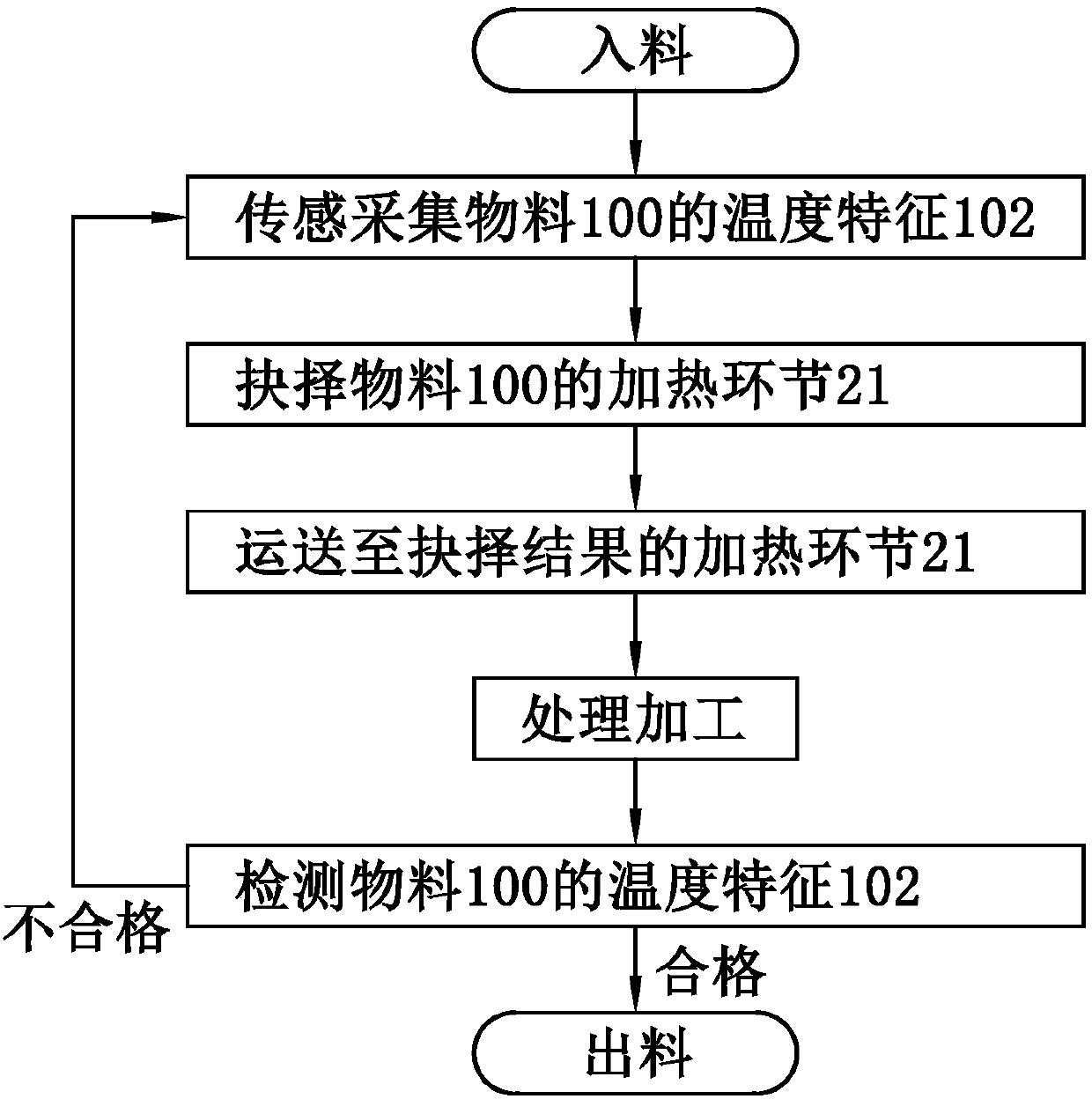

The invention discloses a forging and pressing production method. The forging and pressing production method comprises the following steps that 601, at least one material is fed; 602, at least one characteristic of the material is collected; 603, according to the collected characteristics of the material, a forging and pressing treatment mode of the material is selected; 604, the material is conveyed to a selection result; 605, the material is processed according to the selected treatment mode; and 606, the manufactured material is output. According to the forging and pressing production method, at least one material can be automatically formed by being subjected to hot melting and forging and pressing without manual operation, so that large-batch production of the material is finished.

Owner:宁波钰印智能科技有限公司

Forging and pressing production system

PendingCN110026512ARealize automated productionNo manual operationForging/hammering/pressing machinesForging press drivesHot meltForge

Owner:NINGBO TEXOON BRASSWORKS CO LTD

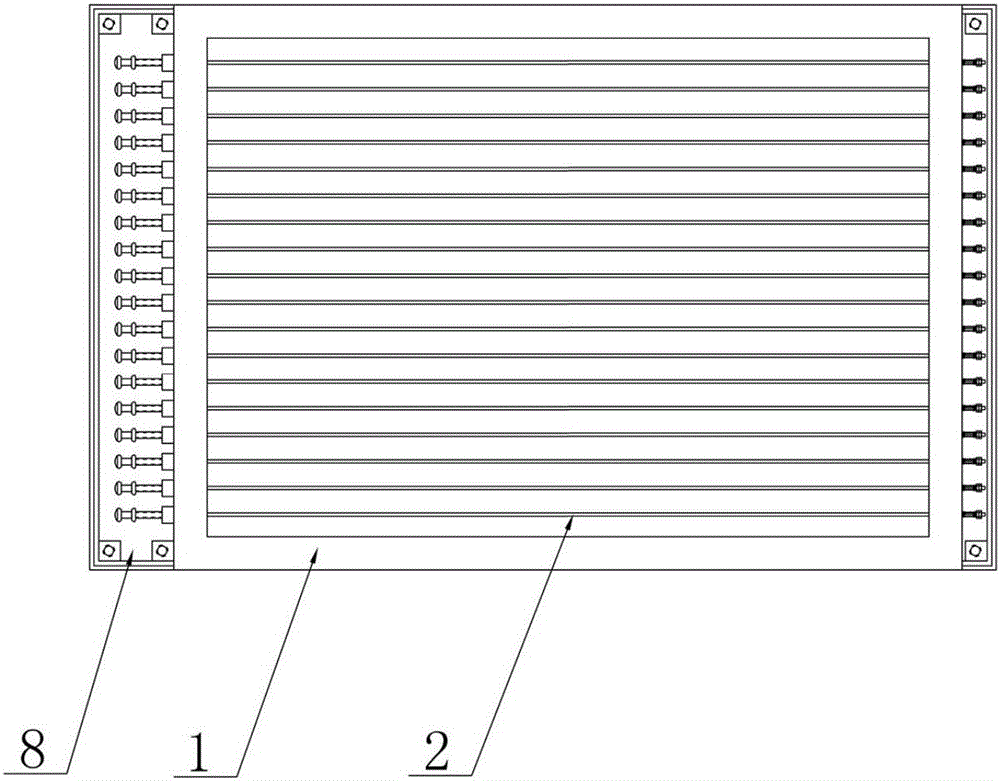

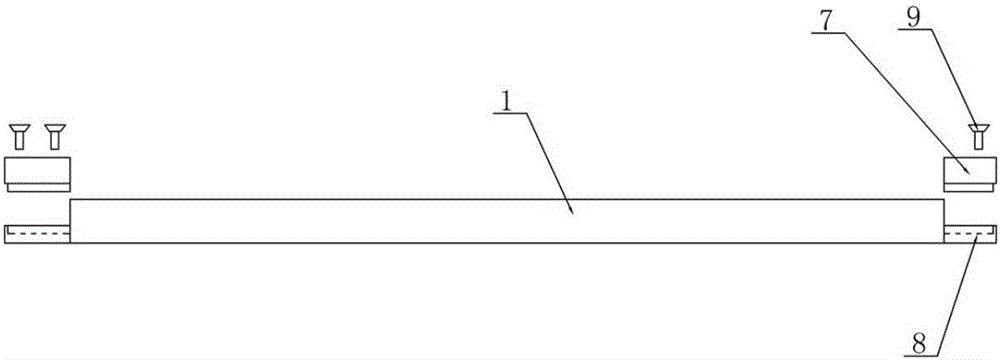

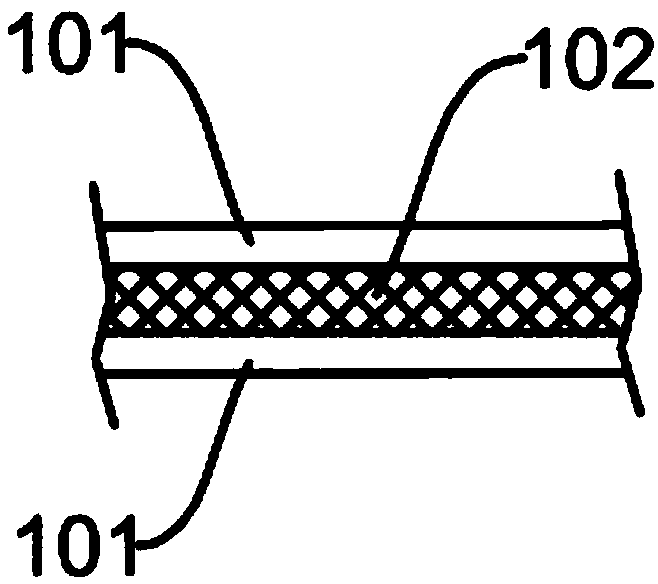

Foldable grill component

InactiveCN105919452AEffective working statusFully supportedRoasters/grillsDual actionArchitectural engineering

The invention belongs to the technical field of barbecue, and relates to a foldable grill component which comprises a frame body, support steel wires evenly juxtaposed in the frame body and tightening mechanisms arranged at one ends of the support steel wires. Each tightening mechanism comprises an outer tightening sleeve with an internal thread and embedded in the frame body, end caps arranged at two ends of each support steel wire, and an inner tightening sleeve with an external thread and sleeving one end of each support steel wire, and the outer tightening sleeve and the inner tightening sleeve match and correspond to each other. The foldable grill component is reasonable in design, the steel wires are under certain prestressed state through dual action of the tightening mechanisms and pre-tensioning springs so as to fully support barbecue and prevent the barbecue from accumulating in the middle, and quality of the barbecue is improved; the foldable grill component can straighten the deformed steel wires used for a long time, so that the effective working condition of the steel wires is realized.

Owner:石伟赟

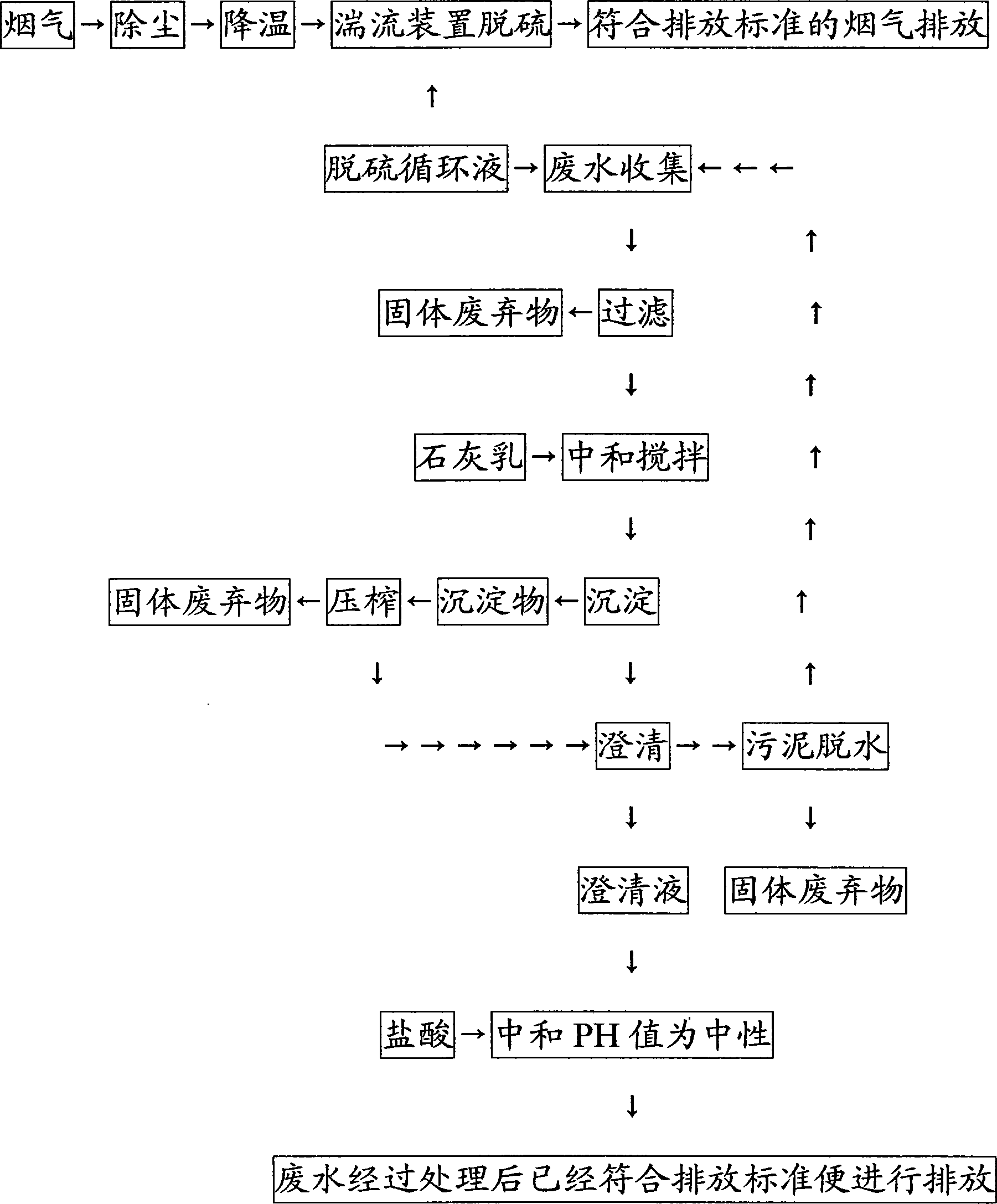

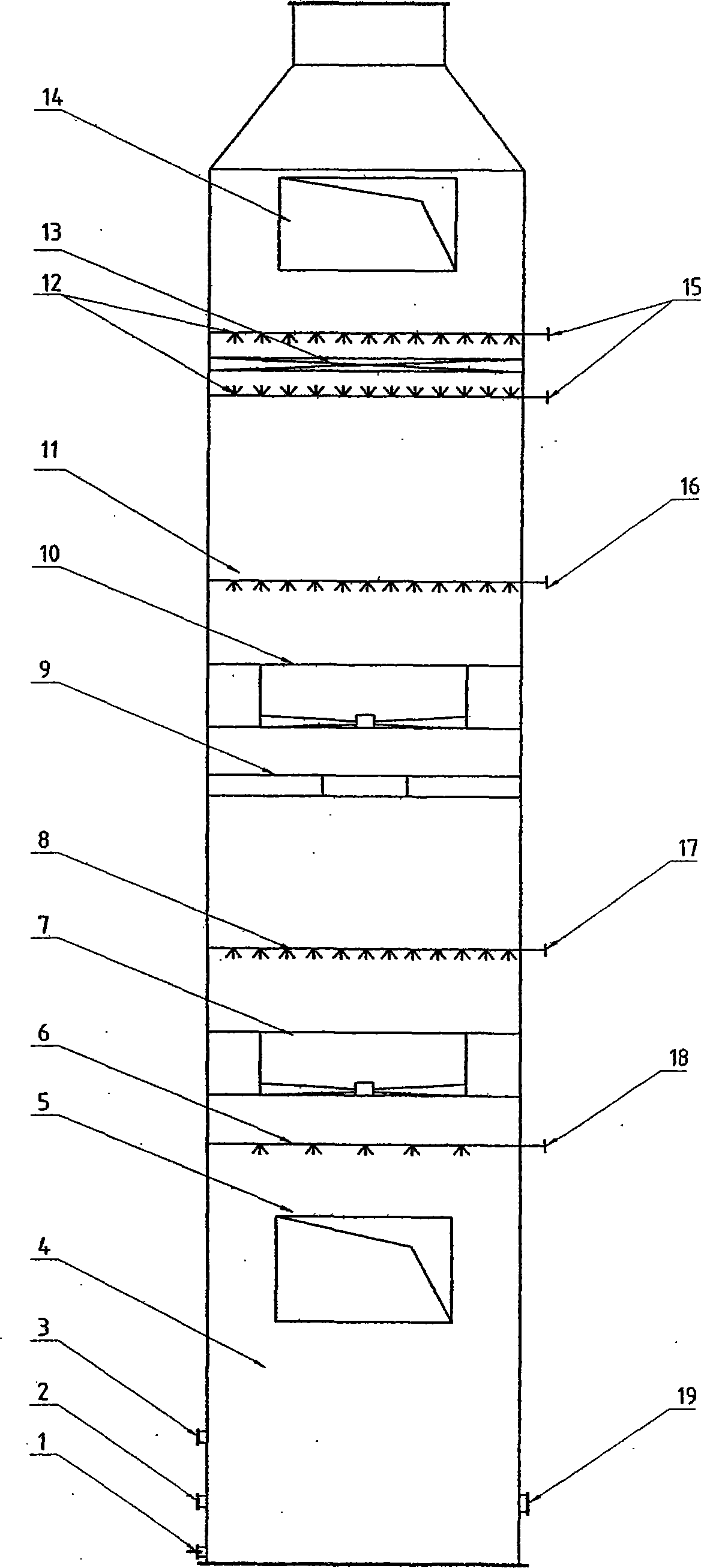

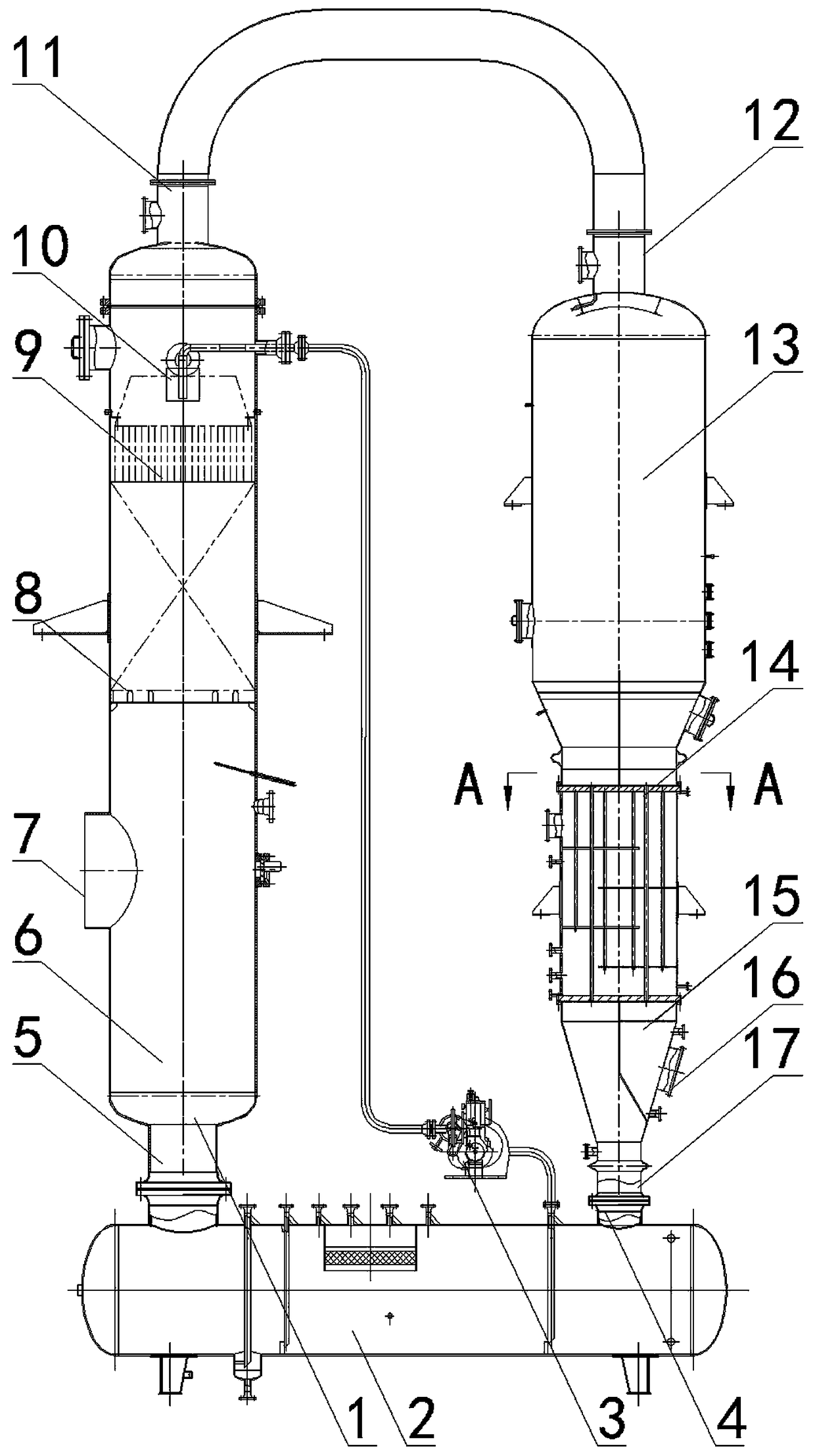

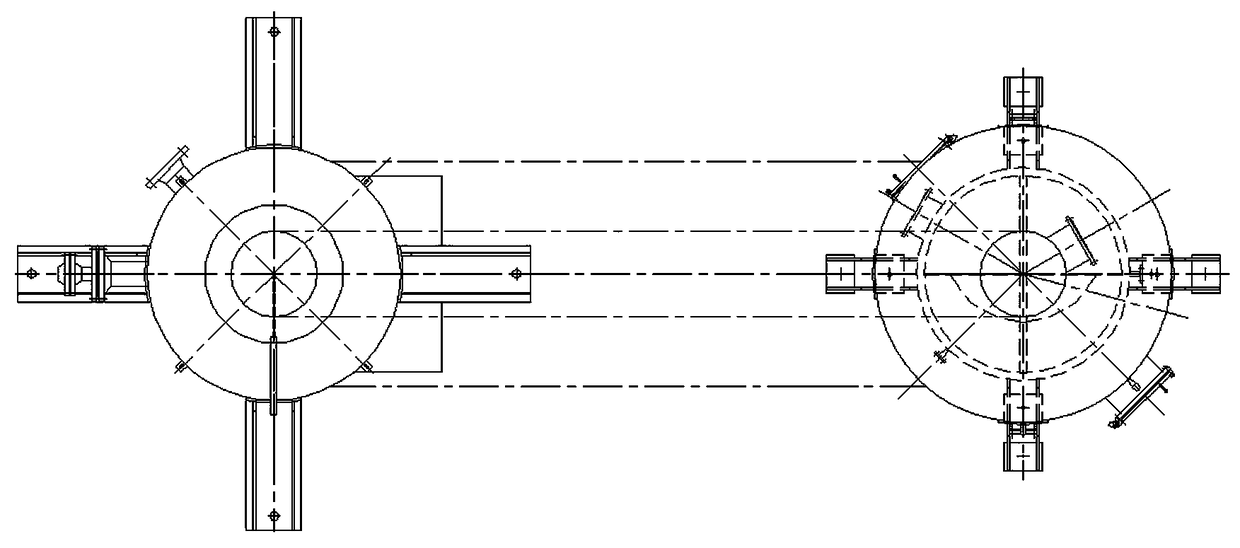

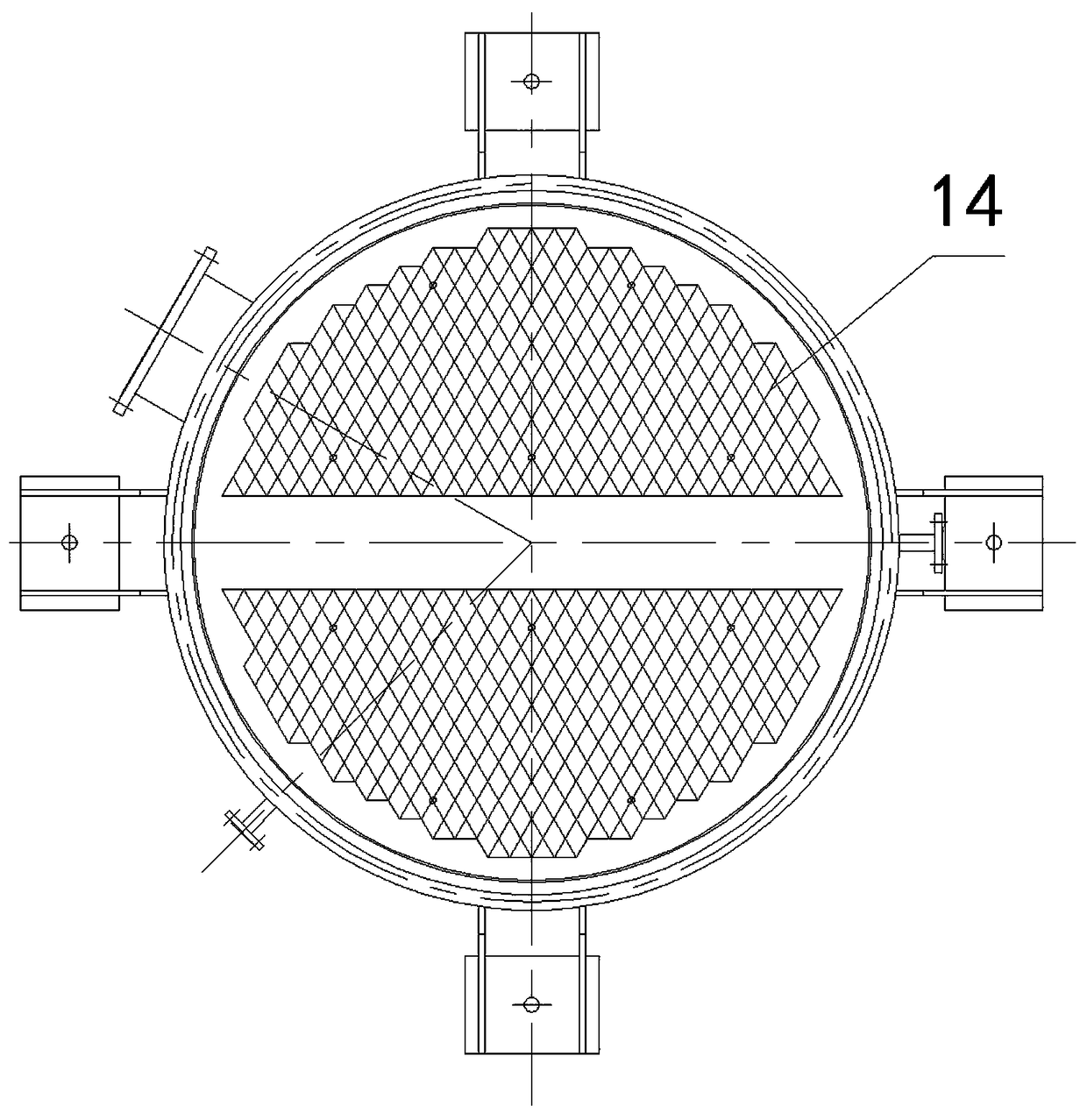

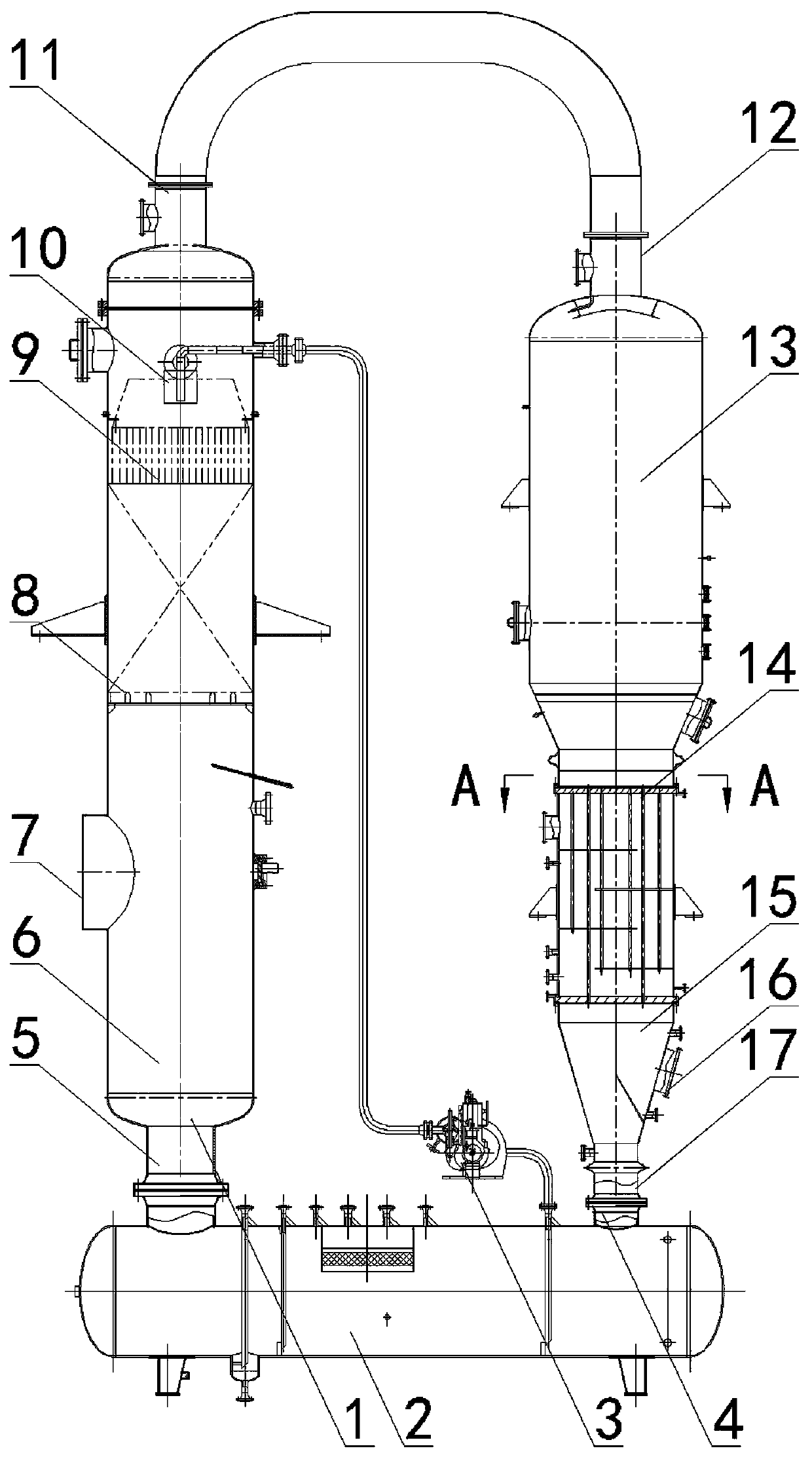

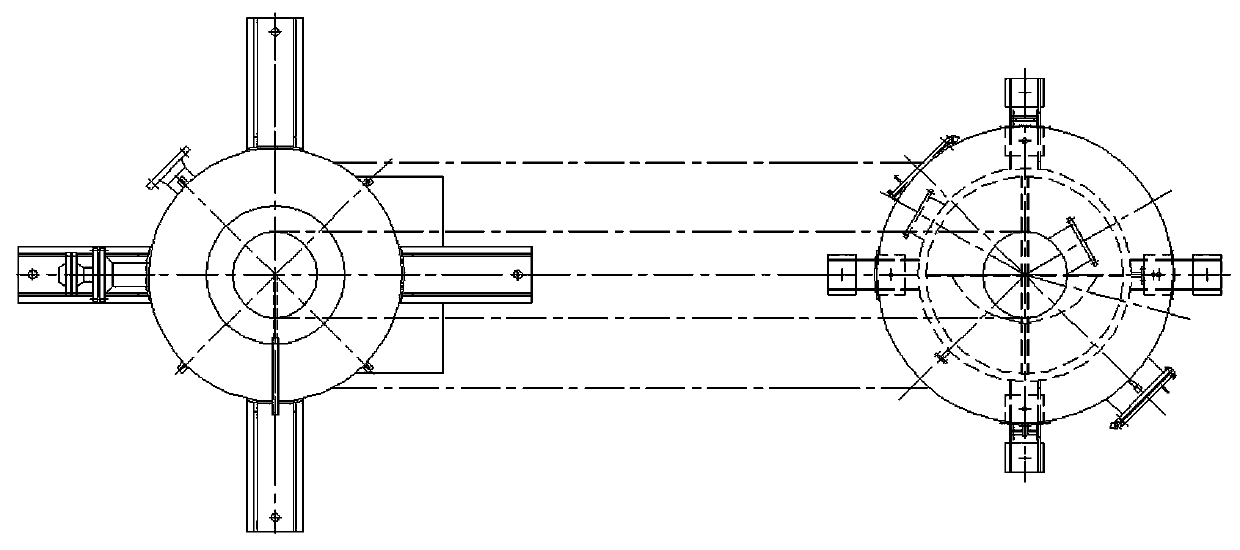

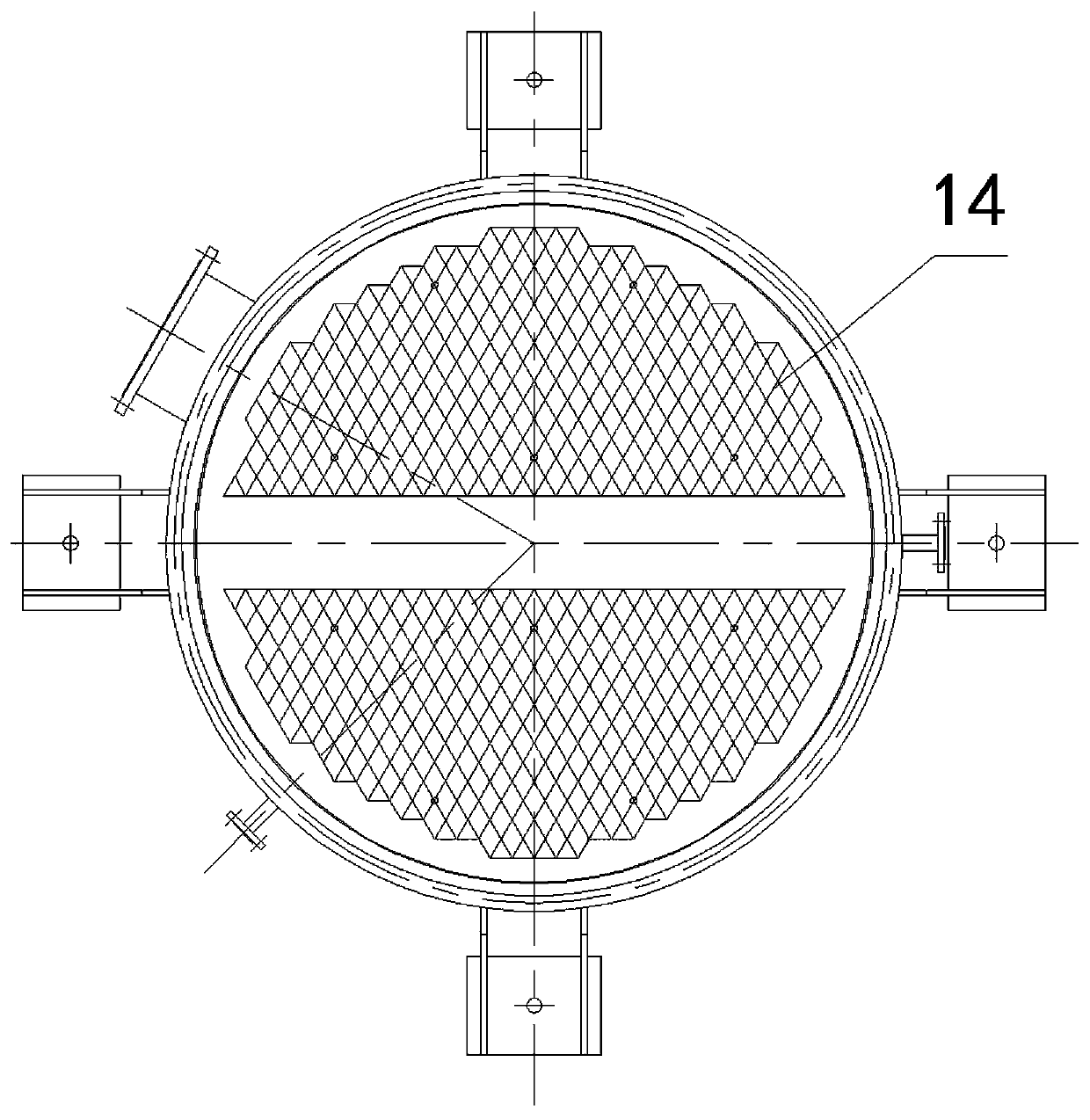

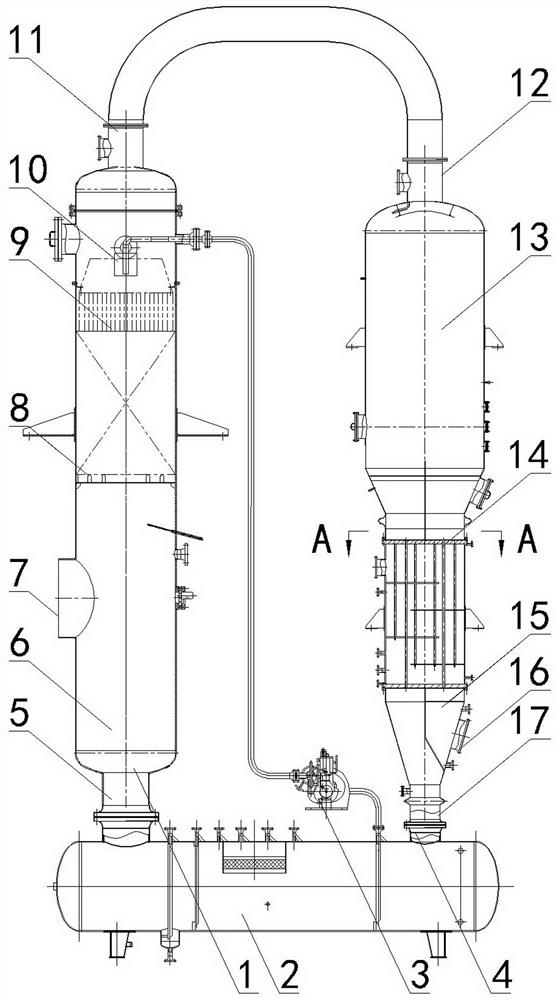

Process technology for turbulent wet-process flue gas desulfurization and desulfurization wastewater treatment

InactiveCN104028097AAdvanced technology and scienceEasy to operateDispersed particle separationMultistage water/sewage treatmentFlue gasEngineering

The invention discloses a process technology for turbulent wet-process flue gas desulfurization and desulfurization wastewater treatment and relates to the technical field of environmental protection. A body of a device is provided with a flue gas inlet and a flue gas outlet and is fixed with a blow-off pipe, a desulfurizing agent supplementing inlet, a water pipe and a desulfurizing agent outlet, the body between the flue gas inlet and the flue gas outlet is fixed with a desulfurizing agent inlet, a first-stage turbocharging turbulator, a first-stage desulfurizing agent inlet, a receiving tank, a second-stage turbocharging turbulator, a second-stage desulfurizing agent inlet, a first water inlet pipe, a demister and another water inlet pipe respectively from bottom to top, a liquid outlet pipe of the receiving tank penetrates out of the body, the desulfurizing agent inlet is fixed with a spray nozzle, the desulfurizing agent inlet is fixed with a first-stage spray nozzle, the second-stage desulfurizing agent inlet is fixed with a second-stage spray nozzle, and the water inlet pipes are fixed with water spray nozzles; and the wastewater treatment process comprises the steps of collecting wastewater, filtrating, neutralizing with lime milk, precipitating, clarifying, neutralizing with hydrochloric acid and then draining. The process technology is applied to flue gas desulfurization and wastewater treatment; and the device is ingenious, and the effect is good.

Owner:BEIJING ZHONGYE LONGSHENG ENVIRONMENTAL PROTECTION TECH

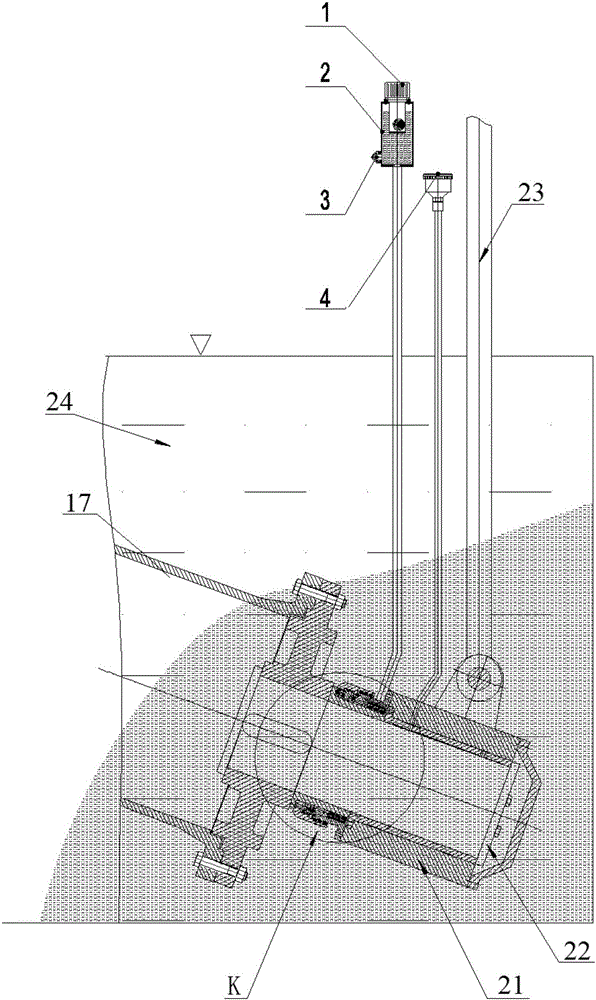

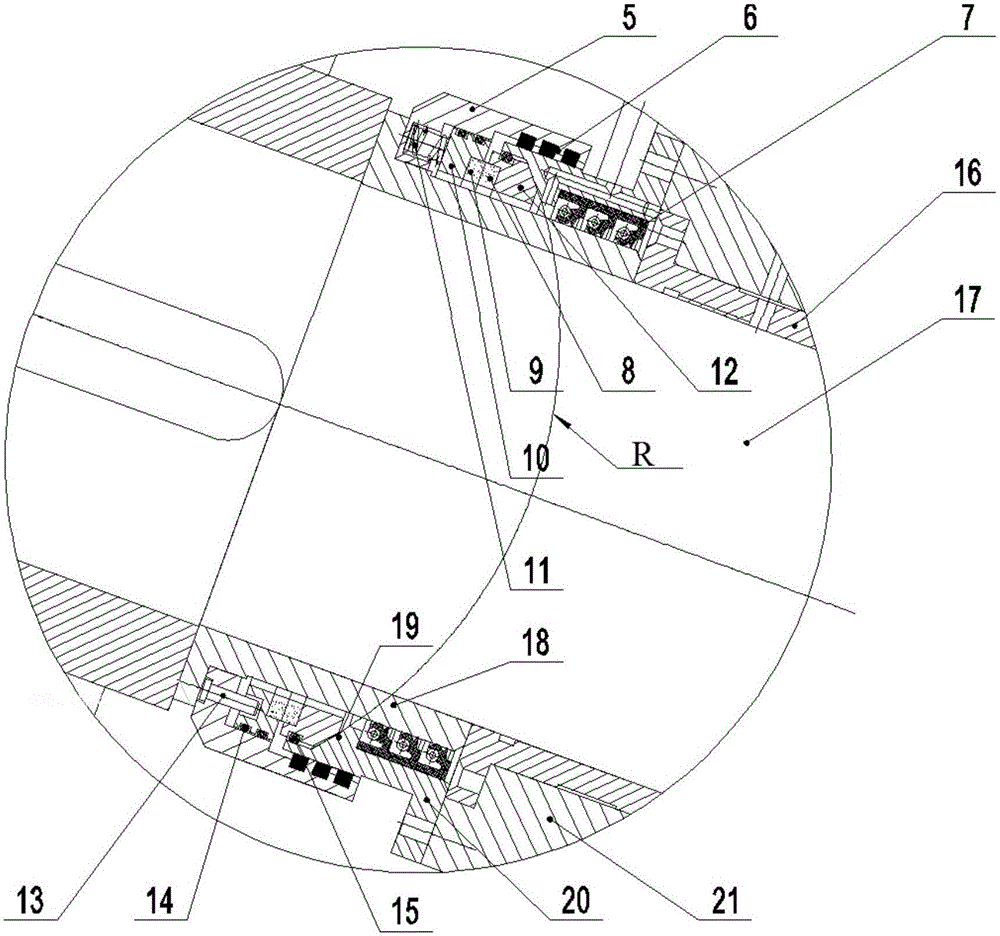

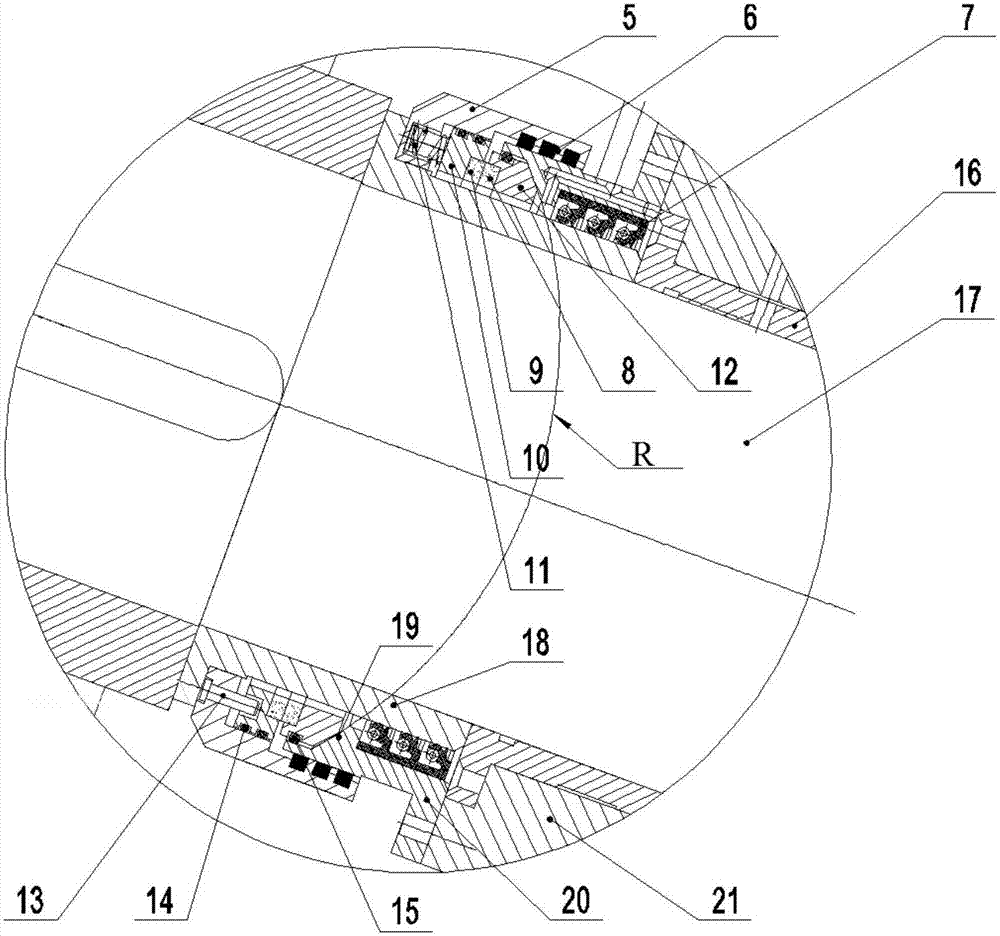

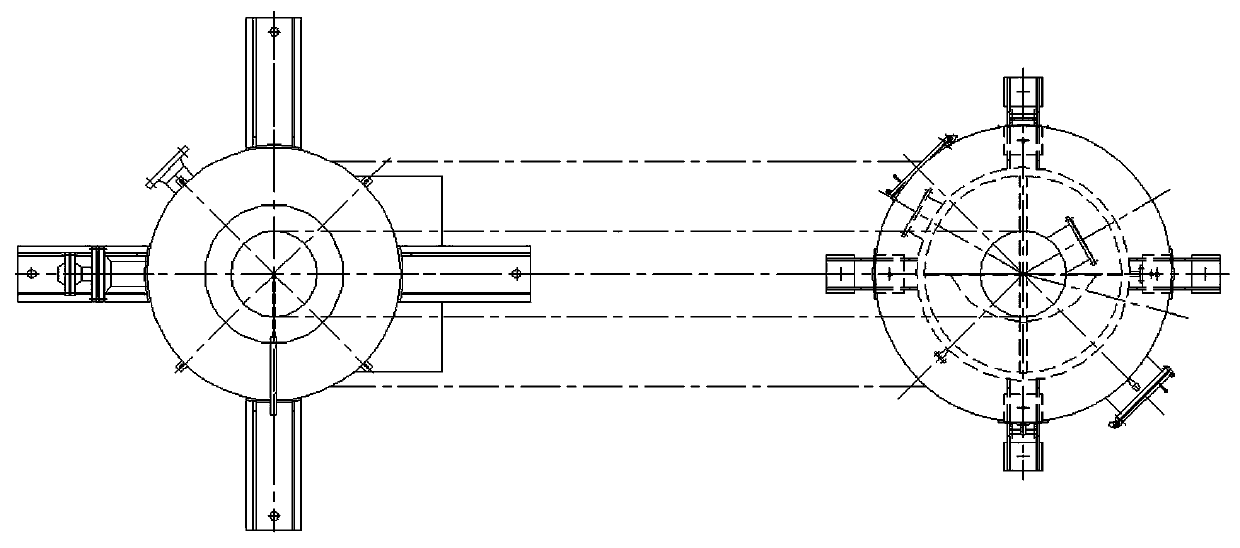

Underwater bearing of flush slag stirring cage machine and sealing device of underwater bearing

The invention discloses an underwater bearing of a flush slag stirring cage machine and a sealing device of the underwater bearing, and belongs to the technical field of stirring cage machines. The underwater bearing comprises three stages of sealing structures. A combined labyrinth seal serves as the first stage, that is, a sealing seat is fixed to a bearing pedestal, and an inverted sealing cup is fixed to a shaft sleeve; and a clearance between the inverted sealing cup and the sealing seat is sealed through a labyrinth sealing ring. A mechanical seal serves as the second stage, that is, a moving ring is fixed in a moving ring support, the moving ring support is pressed by a spring, and the moving ring support is arranged in the inverted sealing cup; and a static ring is fixed in a static ring support, the static ring support is arranged in the sealing seat, a spindle of the stirring cage machine drives the moving ring support to rotate, and then the moving ring is driven to rotate relative to the static ring. A combined frame oil seal serves as the third stage and comprises the multi-layer combined dual-lip frame oil seal. The underwater bearing is sealed, and therefore the service life of the bearing is prolonged to one year or above from three months, the equipment maintenance amount is relieved, production cost is reduced, and the underwater bearing can be suitable for similar work conditions decreased the fields of smelting, chemical engineering and the like.

Owner:马鞍山市方正机械制造有限责任公司

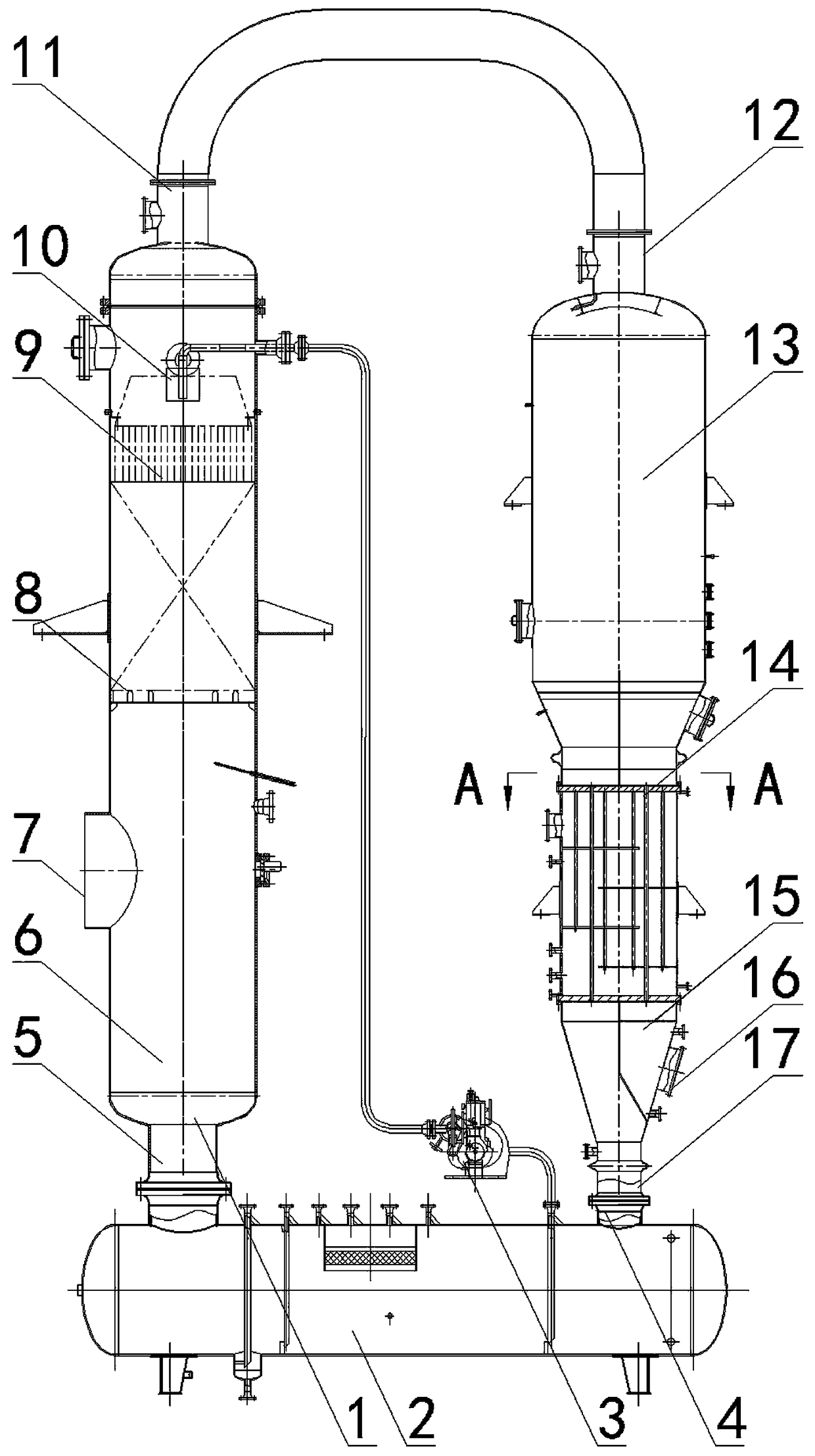

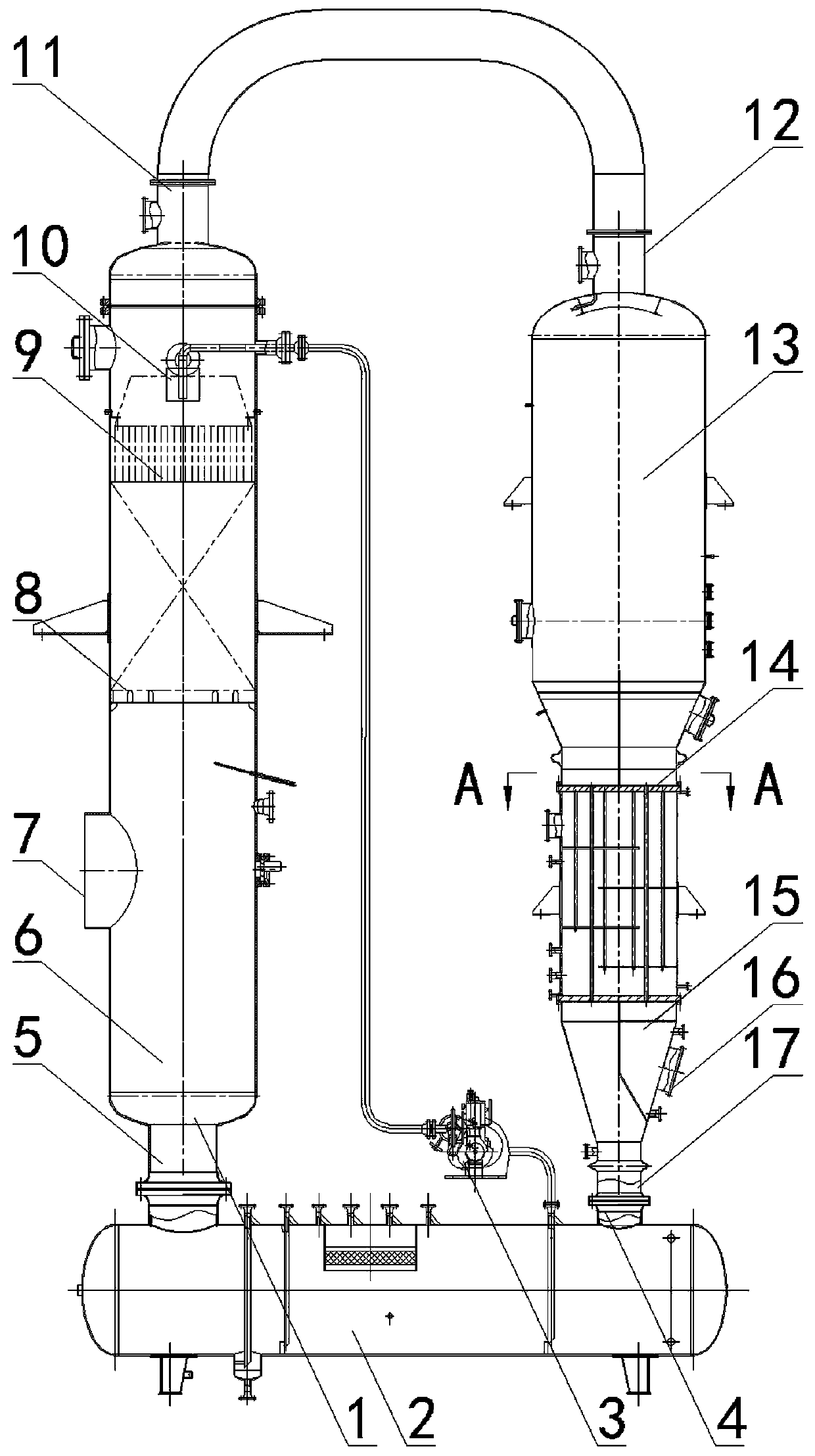

An operation method of a washing and absorbing device for preparing electronic-grade hydrogen fluoride

ActiveCN109200764AThere will be no clogging or even backflow problemsEffective working statusGas treatmentDispersed particle separationHydrogen fluorideTemperature control

The invention relates to the technical field of fluorine chemical engineering and particularly relates to an operation method of a washing and absorbing device for preparing electronic-grade hydrogenfluoride. The method is characterized in that tail gas is fed through a gas feeding duct, with the temperature of the tail gas at this time being 19-21 DEG C; the tail gas flows upward through a filler and a liquid distributing grid tray in the washing and absorbing column and is subjected to mass and heat transfer with a hydrofluoric acid condensate sprayed by a spraying pipe member; the cooled tail gas enters a tail gas inlet of a condensation column through a gas discharging duct, is subjected to heat transfer with a condensation tube plate, then passes through a liquid removing device andis discharged through a tail gas discharging port; the temperature of the tail gas discharging port is controlled to be 9-10 DEG C; the hydrofluoric acid condensate condensed in the washing and absorbing column is gathered by the filler, and flows through a liquid collection tube along the wall of the washing and absorbing column to a circulation storage tank; the hydrofluoric acid condensate condensed in the condensation column flows to the circulation storage tank through a condensate outlet; and a circulation pump assembly allows the hydrofluoric acid condensate in the circulation storage tank to return to the spraying pipe member and to wash condensation tail gas.

Owner:东营睿港管道工程有限责任公司

Pen making machine

Belonging to the pen making field, the invention specifically relates to a pen making machine. The machine of the invention comprises a frame which is provided with a nib glue spraying mechanism and a plug device for plugging of a nib and penholder. The plug device includes a nib conveying mechanism for conveying the nib to be plugged. The nib glue spraying mechanism is installed on the lateral of the nib conveying mechanism. And the glue spraying nozzle directs the inside of a cavity of the nib that is to be plugged and located on the nib conveying mechanism, so that a rapid and effective connection of the nib glue spraying process and the nib and penholder plugging process can be realized. While the plugging and assembling efficiency of the nib and penholder is improved, meanwhile, the assembling quality and product yield are also guaranteed. The machine can operate stably and reliably.

Owner:卫青山

Forging production method

A forging production method, comprising: 601: inputting at least one material; 602: collecting at least one characteristic of the material; 603: determining the forging treatment method of the material according to the collected characteristic of the material; 604: Send the material to the decision result; 605: Process the material according to the selected processing method; and 606: Output the manufactured material. Without manual operation, at least one material can be formed automatically through hot melting and forging, so as to complete the production of the material in large quantities.

Owner:宁波钰印智能科技有限公司

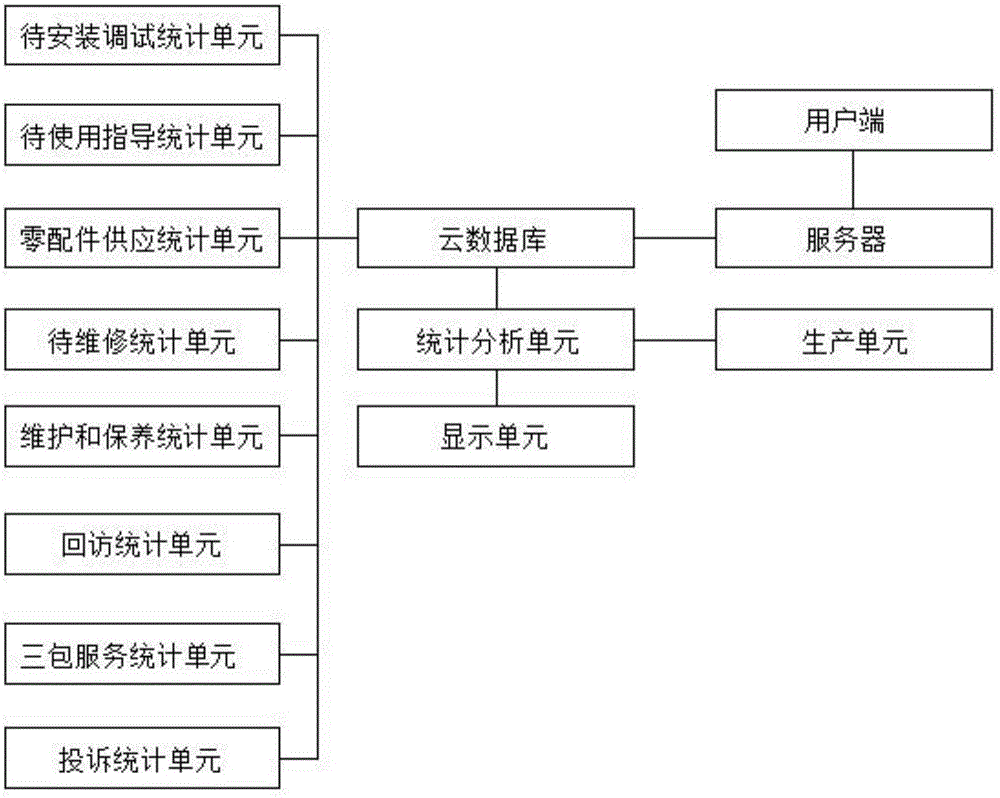

Product after-sale information statistical system

InactiveCN106327264AEasy to superviseNovel module structureDatabase distribution/replicationSpecial data processing applicationsInformation processingQuality control

The invention discloses a product after-sale information statistical system, and belongs to the technical field of information processing. The system comprises a cloud database, a server and a user side, wherein the user side is connected with the cloud database via the server; the cloud database is provided with a to-be-installed / debugged statistical unit, a to-be-technically-guided statistical unit, a part supply statistical unit, a to-be-maintained statistical unit, a maintenance statistical unit, a visit statistical unit, a three-guarantee service statistical unit and a complaint statistical unit; the cloud database is connected to a statistical analysis unit; and the statistical analysis unit is provided with a display unit and a production unit. The system solves the technical problems that the quality control in production is imperfect, the after-sale maintenance cannot be quickly finished, the quality information of products in market cannot be timely and accurately learnt and the like, realizes management of information at the stages of production, detection, installation, maintenance and the like of household appliances, facilitates supervision on product quality and improves later after-sale service level.

Owner:安徽云图信息技术有限公司

A washing and absorbing device for preparing electronic-grade hydrogen fluoride

ActiveCN109200765AThere will be no clogging or even backflow problemsEffective working statusDispersed particle separationHydrogen fluorideCommunicating vessels

The invention relates to the technical field of fluorine chemical engineering and particularly relates to a washing and absorbing device for preparing electronic-grade hydrogen fluoride. The device ischaracterized by including a washing and absorbing column, a circulating storage tank, a circulating pump assembly and a condensation column. The bottoms of the washing and absorbing column and the condensation column communicate with the circulation storage tank to form a U-shaped communicating vessel.

Owner:三立福新材料(福建)有限公司

a rainwater filter

ActiveCN104436794BAvoid enteringAvoid harmStationary filtering element filtersWater filterEngineering

The present invention provides a rainwater filter, which comprises a roughly elliptical shell, and the shell includes an upper shell, a filter element and a lower shell which are sequentially fitted together, wherein a rainwater collection pipe is arranged on the upper part of the upper shell interface; the lower part of the lower shell is provided with a sundry discharge port, the side of the lower shell is provided with a clean water discharge port, and the center of the lower shell is provided with a sundry port communicating with the sundry discharge port Collecting port, the space between the outer wall of the sundries collecting port and the lower housing forms a clean water collecting chamber; the center of the filter element is provided with a water diversion plate, and an annular filter is arranged below the water diversion plate The mesh surface of the annular filter screen gradually slopes downward along the end surface of the outer ring towards the end surface of the inner ring. The rainwater filter of the present invention can automatically remove sundries in rainwater, and can quickly discharge the sundries. The rainwater filter has the characteristics of simple structure, ingenious design and good filtering effect.

Owner:BEIJING TIDELION S&I RAINWATER HARVESTING TECH CO LTD

A dual-mode amplification multiplex distribution system and distribution method with anti-interference function

ActiveCN111505674BReduce in quantityReduce construction difficultySatellite radio beaconingMultiplexingInterference resistance

The invention discloses a dual-mode amplification multi-channel distribution system and a distribution method with anti-interference function. The invention has a three-way GPS / Beidou antenna unit, which is used to detect the first radio frequency active unit and the second radio frequency active unit through the detection and control unit. The signal strength of the RF active unit and the third RF active unit, and control the switching of the RF switch and the multi-channel GPS / Beidou signal switching unit. The third GPS / Beidou antenna unit is connected with an anti-interference module that can be interfered by other antenna units When unable to work, keep GPS / Beidou signal uninterrupted output, the invention has three-channel input and multi-channel output, effectively reducing the number of antenna feeder systems, reducing construction difficulty and cost.

Owner:SHAANXI TIANJI COMM TECH

A kind of underwater bearing and sealing device of water flushing slag mixing machine

The invention discloses an underwater bearing of a flush slag stirring cage machine and a sealing device of the underwater bearing, and belongs to the technical field of stirring cage machines. The underwater bearing comprises three stages of sealing structures. A combined labyrinth seal serves as the first stage, that is, a sealing seat is fixed to a bearing pedestal, and an inverted sealing cup is fixed to a shaft sleeve; and a clearance between the inverted sealing cup and the sealing seat is sealed through a labyrinth sealing ring. A mechanical seal serves as the second stage, that is, a moving ring is fixed in a moving ring support, the moving ring support is pressed by a spring, and the moving ring support is arranged in the inverted sealing cup; and a static ring is fixed in a static ring support, the static ring support is arranged in the sealing seat, a spindle of the stirring cage machine drives the moving ring support to rotate, and then the moving ring is driven to rotate relative to the static ring. A combined frame oil seal serves as the third stage and comprises the multi-layer combined dual-lip frame oil seal. The underwater bearing is sealed, and therefore the service life of the bearing is prolonged to one year or above from three months, the equipment maintenance amount is relieved, production cost is reduced, and the underwater bearing can be suitable for similar work conditions decreased the fields of smelting, chemical engineering and the like.

Owner:马鞍山市方正机械制造有限责任公司

A method for preparing an electronic-grade hydrogen fluoride washing and absorbing device

ActiveCN109200764BThere will be no clogging or even backflow problemsEffective working statusGas treatmentDispersed particle separationHydrogen fluorideTemperature control

Owner:东营睿港管道工程有限责任公司

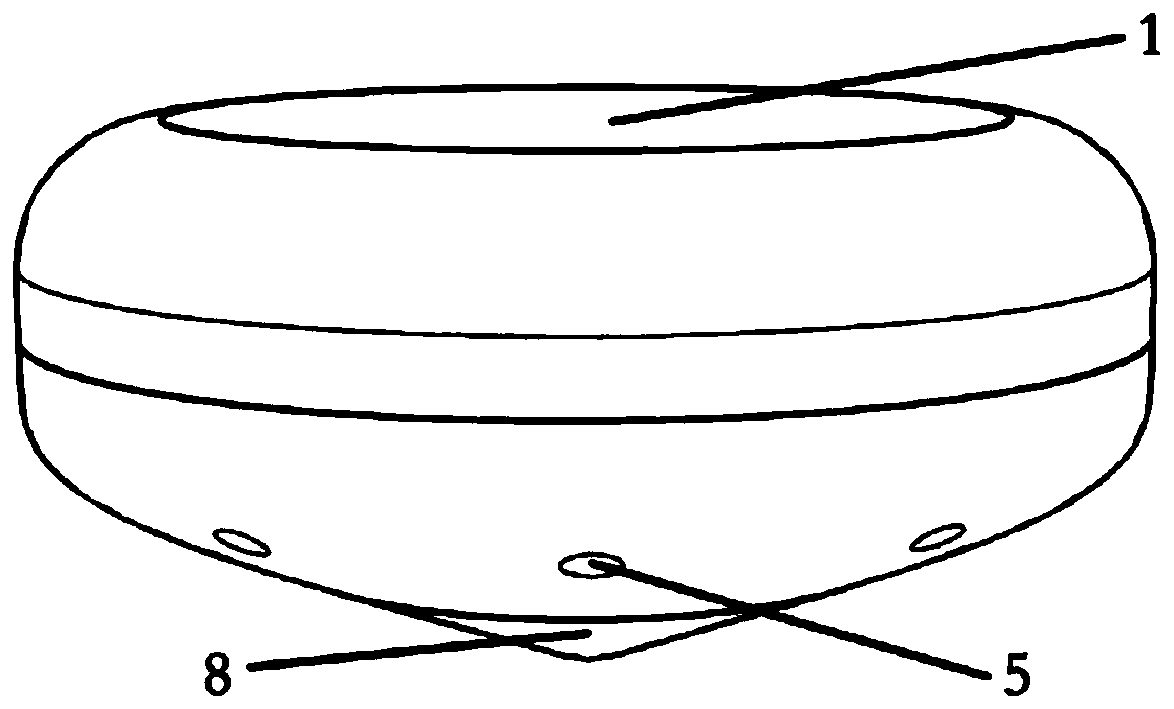

Light intelligent water quality detection system and method

PendingCN111289587AEffective working statusAccurate final dataProgramme controlBatteries circuit arrangementsControl communicationsSmart water

The invention discloses a light intelligent water quality detection system and a light intelligent water quality detection method. The light intelligent water quality detection system comprises a solar photovoltaic panel, a power supply module, a control communication positioning module, a buoyancy piece, a detection part, a counterweight piece and an outer shell, wherein the solar photovoltaic panel is arranged on the upper surface and charges the power supply module, and the power supply module supplies power to the control communication positioning module and the detection part; the buoyancy piece is annularly arranged at the peripheries of the power supply module and the control communication positioning module; the detection part and the counterweight piece are arranged below the buoyancy piece and are wrapped by the outer shell; and the detection part comprises a temperature detection circuit, a PH detection circuit, a turbidity detection circuit, a conductivity detection circuitand a dissolved oxygen detection circuit. According to the light intelligent water quality detection system and the light intelligent water quality detection method, complete detection including intelligent detection, data uploading, analysis, polluted area positioning and the like is conducted and feedback is timely carried out, thus the problems that the pollution cannot be discovered as soon as possible and cannot be effectively treated and further diffusion and aggravation of the pollution are caused when a water area is polluted by human or nature are solved.

Owner:HANGZHOU DIANZI UNIV

A kind of use method of preparing hydrogen fluoride washing tower

ActiveCN108928804BNo clogging or even backflow into the reactorEffective working statusHydrogen fluorideVapor condensationHydrogen fluorideChemical industry

The invention relates to the technical field of fluorine chemical industry and particularly relates to a method for using a washing tower for preparing hydrogen fluoride. The method is characterized in that hydrofluoric acid gas is introduced through a gas guide pipe, upwards flows through a tower tray and a knockout tray in a washing tower body and is subjected to mass transfer and heat transferwith washing acid sprayed by a spraying assembly herein, cooled hydrofluoric acid gas enters a gas inlet of a primary condenser through a gas exhaust opening, the hydrofluoric acid gas is subjected toheat exchange through a condenser pipe plate assembly and then is discharged through a liquid remover and a gas outlet.

Owner:湖南科迈环保设备有限公司

A washing and absorbing device for preparing electronic grade hydrogen fluoride

ActiveCN109200765BThere will be no clogging or even backflow problemsEffective working statusDispersed particle separationHydrogen fluoridePhysical chemistry

Owner:三立福新材料(福建)有限公司

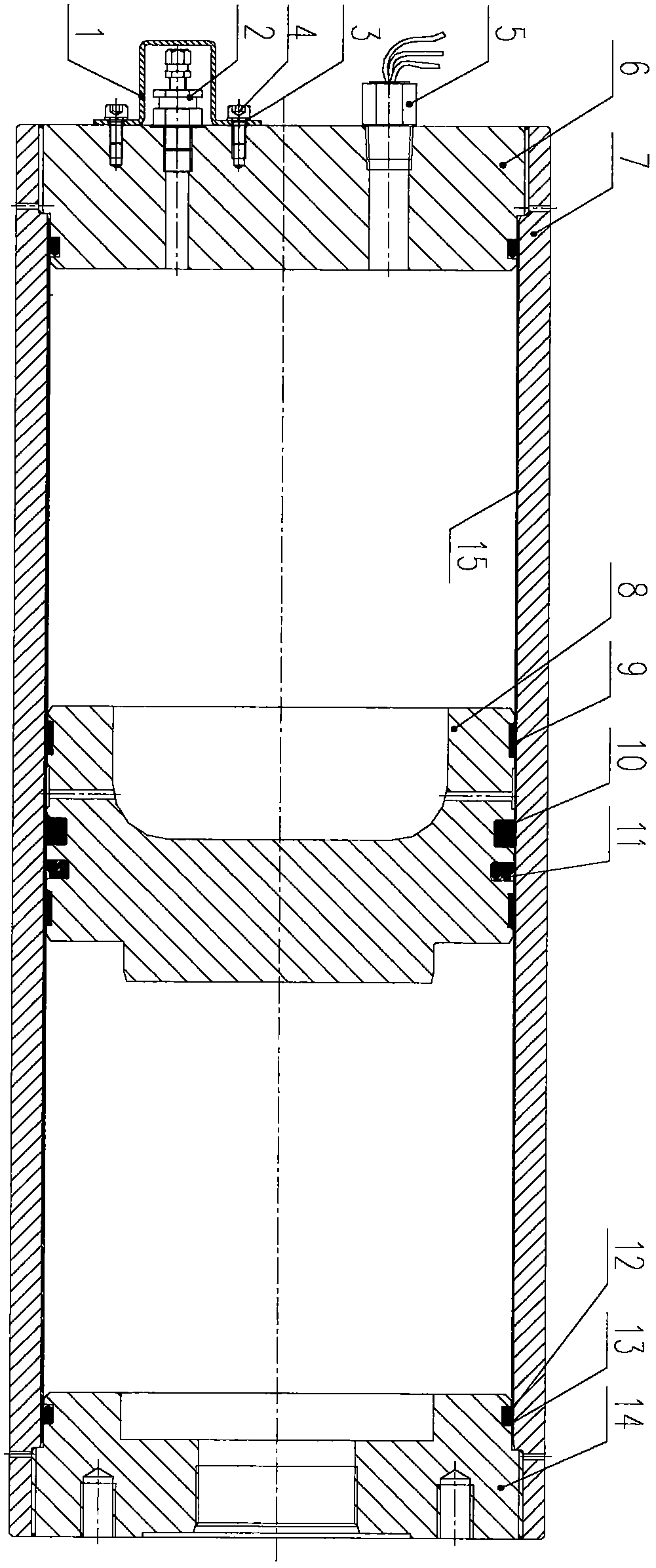

Lined type piston energy accumulator with alarming function

InactiveCN110578715AGuaranteed corrosion resistanceLow cost of industrializationFluid-pressure actuator safetyCapisHigh pressure

The invention discloses a lined type piston energy accumulator with an alarming function. The lined type piston energy accumulator with the alarming function comprises a protective cap, a heavy type inflation valve, light type spring washers, hexagon socket cap screws, a high-pressure medium sensor, a gas side end cover, a shell, a piston, a support ring, a bidirectional seal device, a one-way seal device, O-shaped seal rings, check rings and an oil side end cover. A 316L stainless steel lining is arranged in the shell. The two ends of the shell are provided with the gas side end cover and theoil side end cover through the O-shaped seal rings and the check rings. The gas side end cover is provided with the high-pressure medium sensor and the heavy type inflation valve. The protective capis fixed to the gas side end cover by the light type spring washers and the hexagon socket cap screws and located outside the heavy type inflation valve. The piston is arranged in the shell through the support ring, the bidirectional seal device and the one-way seal device. The lined type piston energy accumulator with the alarming function is reasonable in structural design, good in pressure bearing effect, low in cost and resistant to corrosion, the work state of the energy accumulator can be effectively detected in time, timely replacement and maintenance are guaranteed, and then system functions are guaranteed.

Owner:BUCCMA ACCUMULATOR TIANJIN

A high-efficiency corn flour cake making system and corn cake preparation method

ActiveCN108283956BReduce impurityGuaranteed finenessGrain huskingGrain polishingAgricultural engineeringMagnetic separator

A high-efficiency corn kernel flour and cake making system and a method for preparing corn cakes, wherein the high-efficiency corn kernel flour and cake making system includes a wind separator, a magnetic separator, a crushing and peeling machine, a crushing mechanism, The grinding mechanism, as well as the batching tank and extruder located in the extruding workshop, also includes the feeding channel and the temporary storage tank for finished products. The feeding channel is formed from the ground outside the processing workshop and extends into the processing workshop , connected with the bottom end of the first hoist in the processing workshop. The refining effect is achieved through multi-stage screening and re-feeding and multi-stage grinding and screening mechanisms, and the feeding, milling, puffing, and discharging are located in different workshops, which is convenient for the operation of feeding and discharging, and avoids operators from being in the noisy processing workshop. , to avoid mutual interference between the milling and extruding processes, and to reduce the noise of key equipment, air ducts and hoist passages, and to solve the problem of power failure and retention by improving the structure of the joints of the air ducts.

Owner:成都昌盛鸿笙食品有限公司

Large and medium high concentration medical waste water biofilter sterilization and purification treatment system

InactiveCN101591102AFacilitate the realization of automatic controlEfficient reproductionMultistage water/sewage treatmentSustainable biological treatmentHigh concentrationSludge

The invention relates to a large and medium high concentration medical waste water biofilter sterilization and purification treatment system, comprising a closed type collecting tank, a closed type primary sedimentation tank, a closed type sludge holding tank, a closed type sludge disinfection tank, a closed type sewage sterilization tank, a preaeration tank, a biological filtering tower and a secondary sedimentation tank which are sequentially connected; wherein the intake pipe of the biologic filtering tower is arranged at the upper part of the tower body and the biologic filtering tower is provided with a plurality of nozzles, multilayer filler in the tower, an air outlet at the top part, an air inlet on the lower side face and a water channel at the bottom; and the water outlet of the secondary sedimentation tank is connected with a water reservoir. The invention has good biologic safety and is difficult to cause danger of pathogenic microorganism diffusion with good purification effect and high purification degree of output water; and meanwhile the required investment is relatively small and operation and maintenance are convenient.

Owner:BEIJING JINAOHUARONG TECH

An Adaptive Pipeline Dredging Robot

Owner:WUHAN UNIV OF TECH

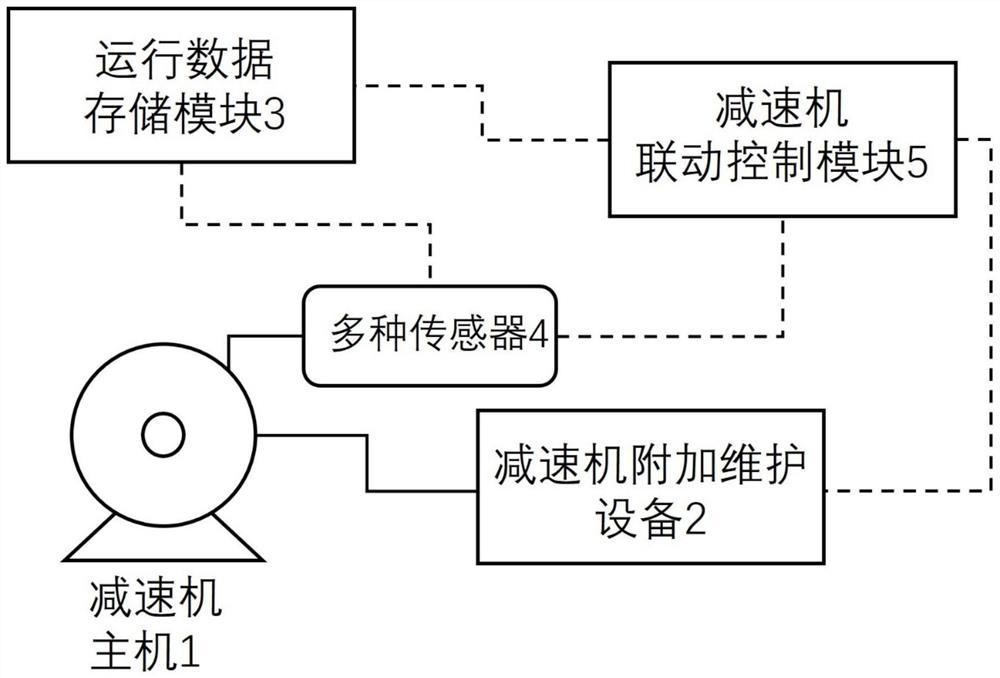

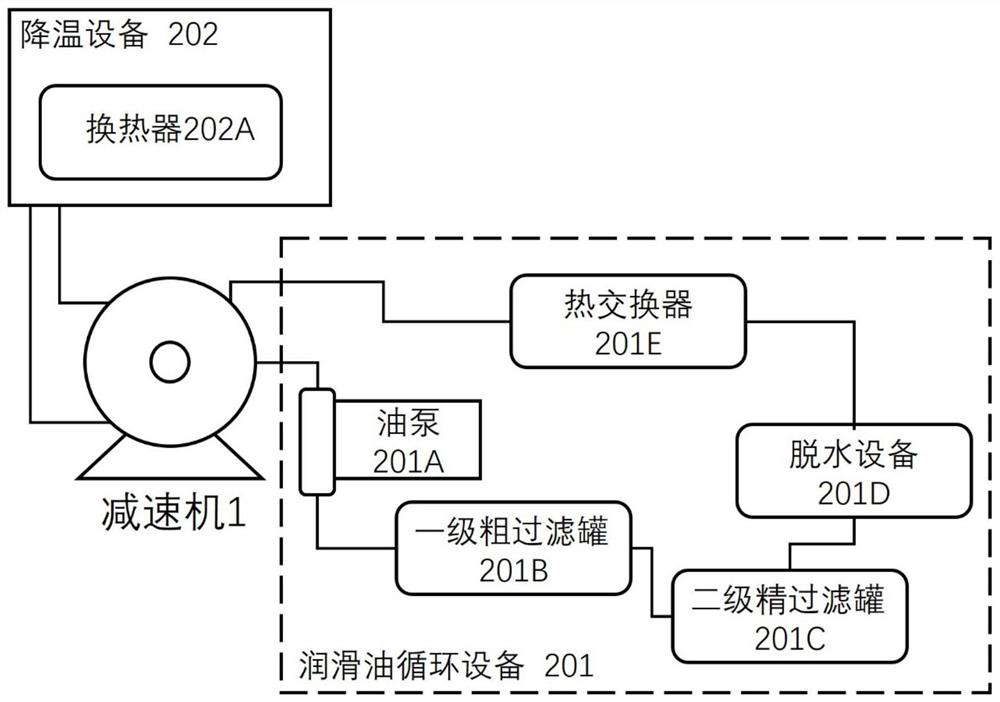

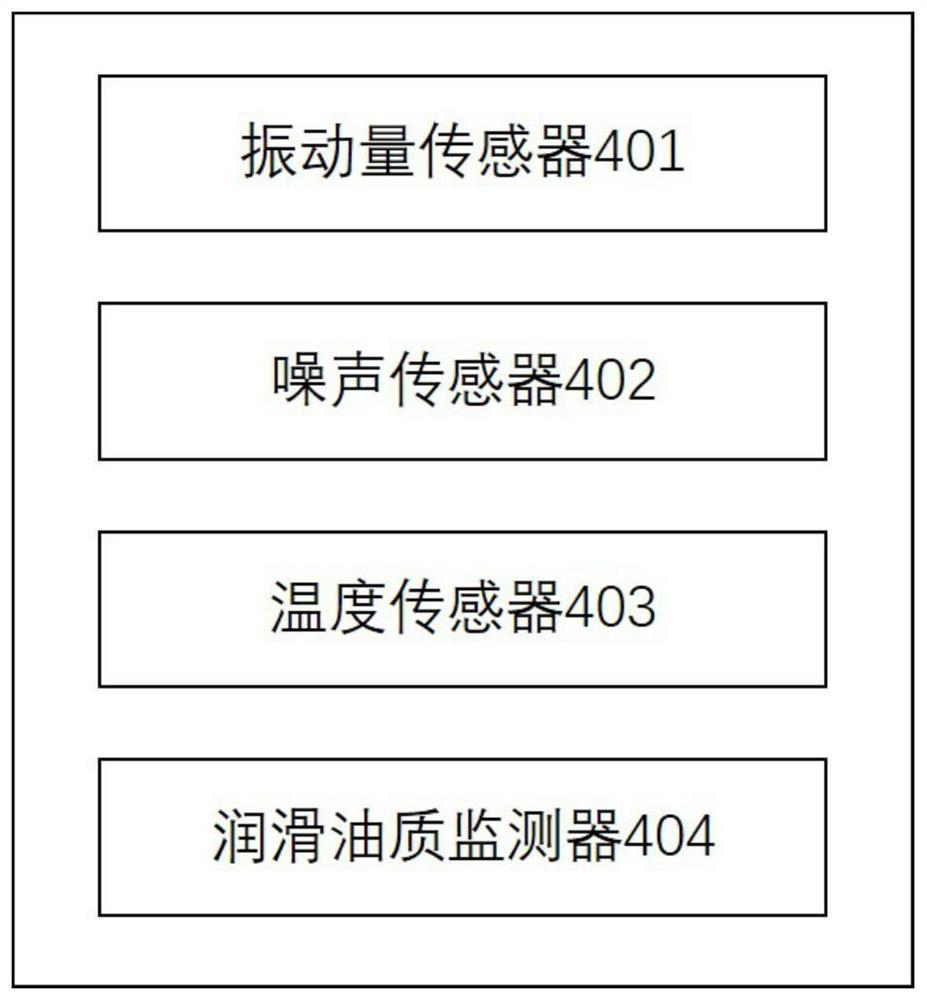

A reducer linkage control system and method based on big data

ActiveCN111981111BEffective working statusGuaranteed normal operationGear lubrication/coolingGearing controlControl systemControl engineering

The present application provides a reduction gear linkage control system and method based on big data. The neural network monitoring unit based on big data training in the present invention can automatically identify the working state of the reducer according to the collected vibration, noise and temperature change signals of the reducer, form a quantitative representation, and then realize the reduction gear and its lubrication according to the quantitative representation of the working state Oil circulation equipment and cooling equipment are effectively linked and controlled, so that the supply and circulation of lubricating oil and the internal temperature adjustment of the reducer can fully match the working state of the reducer.

Owner:JIANGSU GUOMAO REDUCER GRP CO LTD

Continuous type fine processing treatment system for rapid flour preparation from corn kernels

The invention provides a continuous type fine processing treatment system for rapid flour preparation from corn kernels. The system comprises an air separator, a magnetic separator, a crushing and peeling machine, a smashing mechanism and a grinding mechanism which are arranged in a treatment workshop; the system further comprises a feeding channel and a finished product temporary storage tank, wherein the feeding channel is inclined downwards from the ground located on the outer side of the treatment workshop, extends into the treatment workshop and is connected with the bottom end of a firstelevator in the treatment workshop. The refining effect is realized by multi-link screening and feeding as well as the multi-stage grinding and screening mechanism, furthermore, feeding, treatment and discharging are performed in different workshops respectively, so that feeding and discharging are convenient to operate, an operator is prevented from being located in the treatment workshop with larger noise, key equipment, air pipes and elevator channels are subjected to noise reduction treatment, and besides, the condition of retention caused by power outage is solved by structural improvement of air pipe joints.

Owner:中农鸿笙有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com