Vacuum material-sucking dust removal device

A technology of dust removal device and vacuum suction, which is used in transportation and packaging, conveying bulk materials, conveyors, etc., to achieve the effects of improving conveying efficiency, effective working status, and high material-to-air ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

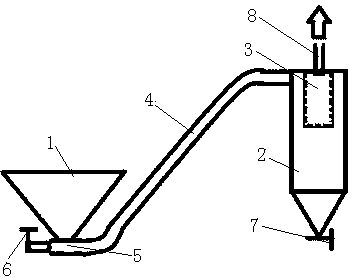

[0011] figure 1 It is shown that the device is composed of three parts connected. Below the buffer hopper 1 is an air-material combination port 5, the mixing port has an air intake control valve 6, this part is combined with the storage box 2 through the suction pipe 4, a filter 3 is designed in the storage box 2, and above the filter 3 is Vacuum port 8. A discharge valve 7 is designed below the material storage box 2 .

[0012] The vacuum suction device is all working under negative pressure, without dust pollution, and the air inlet has an air inlet control valve 6 to control the air intake to control the material conveying speed. The filter 3 in the material storage box 2 can prevent micropowder from entering the vacuum suction port 8 . When the dust reaches a certain thickness, it is automatically peeled off from the filter 3 without ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com