Continuous type fine processing treatment system for rapid flour preparation from corn kernels

A processing system and corn kernel technology, applied in grain processing and other directions, can solve problems such as affecting the physical and mental health of operators in the production environment of the factory area, affecting the smooth progress of transportation, and retaining particles or powder in the air duct. Ensure the effect of impurity removal, filtering and returning smooth and effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

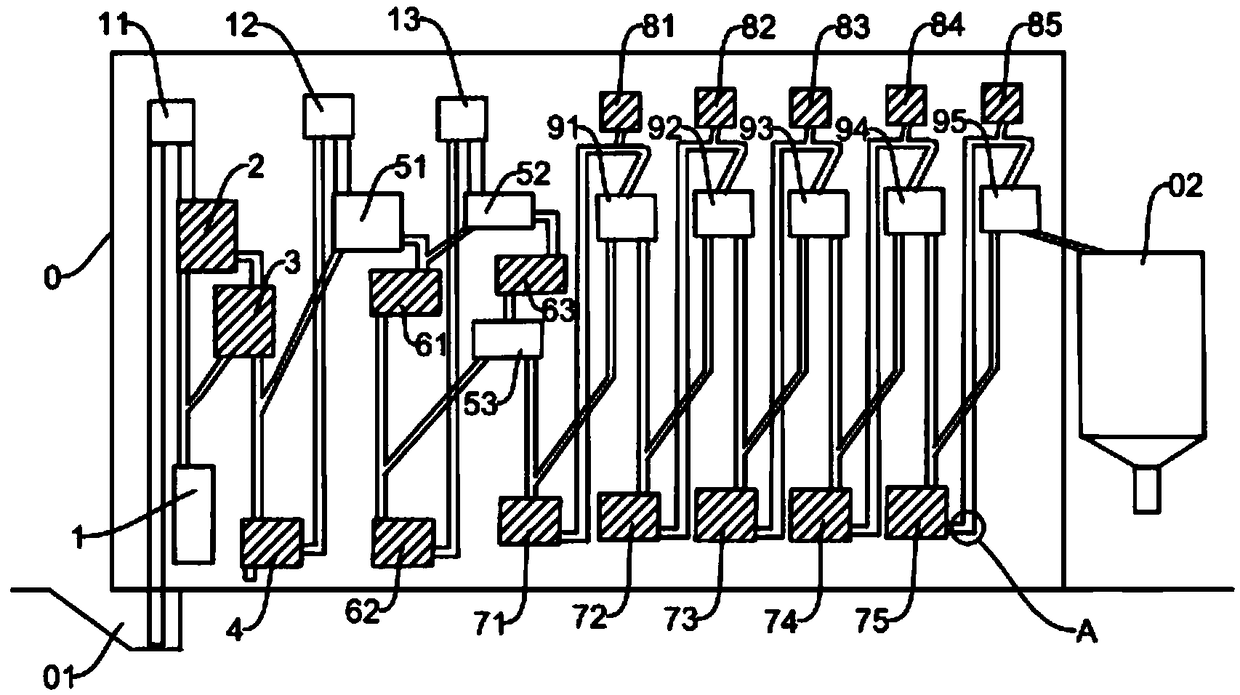

[0030] like Figure 1-7 As shown, a continuous fast milling and finishing treatment system for corn kernels includes a wind separator 2, a magnetic separator 3, a crushing and peeling machine 4, a crushing mechanism, and a milling mechanism located in the processing workshop 0.

[0031] It also includes a feed channel 01 and a finished product temporary storage tank 02. The feed channel 01 is formed downwardly from the ground outside the processing workshop 0, and extends into the processing workshop 0, and is connected with the first hoist 11 in the processing workshop 0 The bottom end is connected, the discharge port on the upper part of the first elevator 11 is connected to the feed end of air separator 2, the discharge end of wind separator 2 is connected downwards to the feed end of magnetic separator 3 through a pipeline, and the discharge end of magnetic separator 3 Connect the feed end of crushing and peeling machine 4 downwards through pipelines, the trash discharge e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com