An operation method of a washing and absorbing device for preparing electronic-grade hydrogen fluoride

An absorption device, hydrogen fluoride technology, applied in chemical instruments and methods, perfluorocarbon/hydrofluorocarbon capture and separation methods, etc., can solve safety accidents, fluorine gas is highly toxic, and increases the difficulty and cost of treatment And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

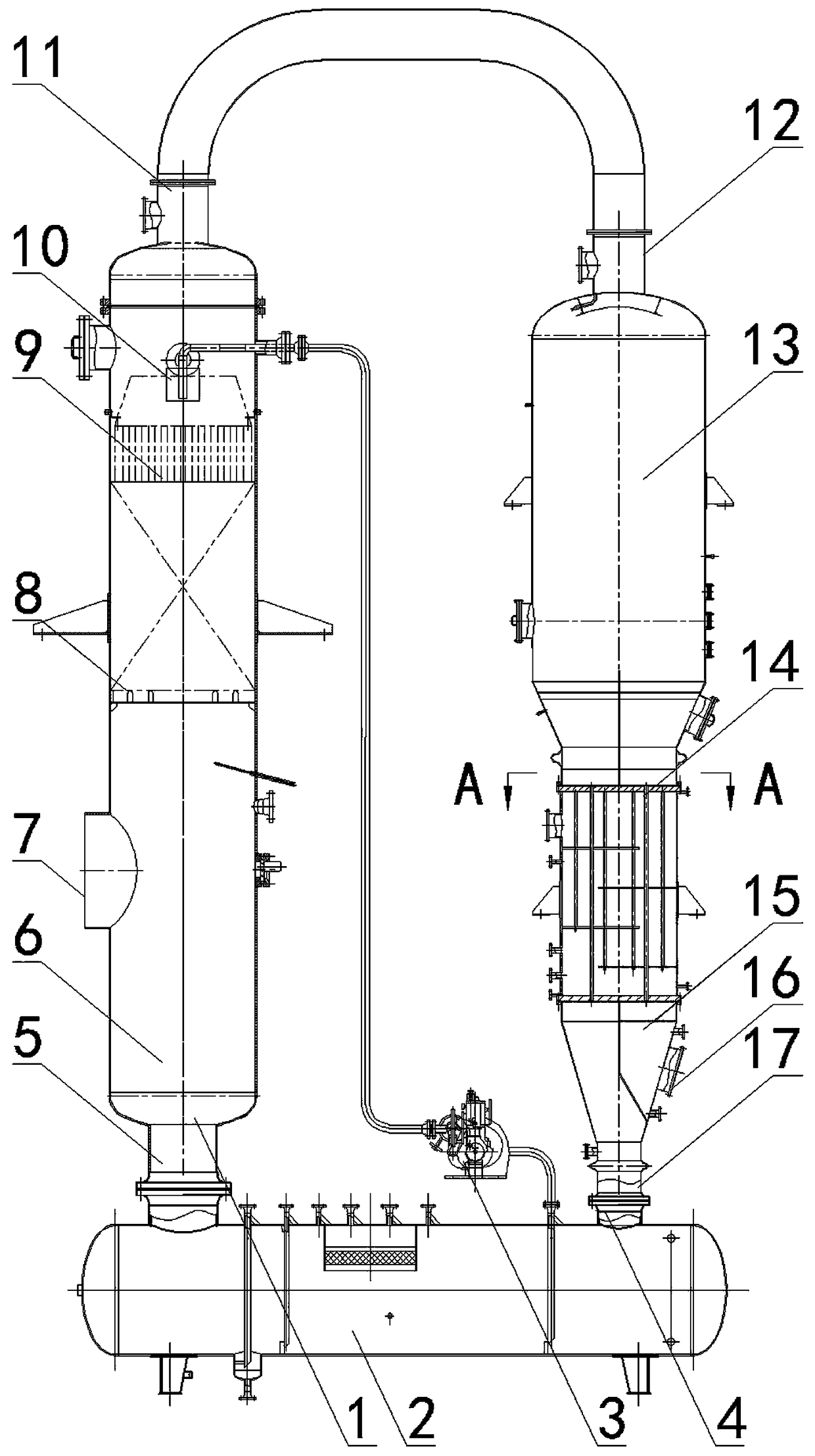

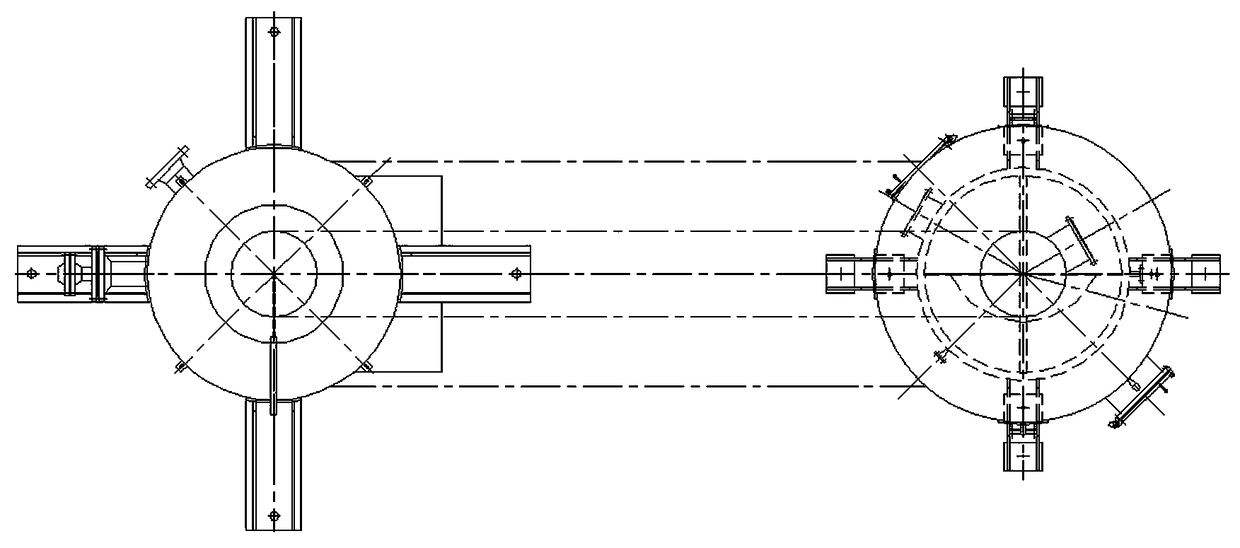

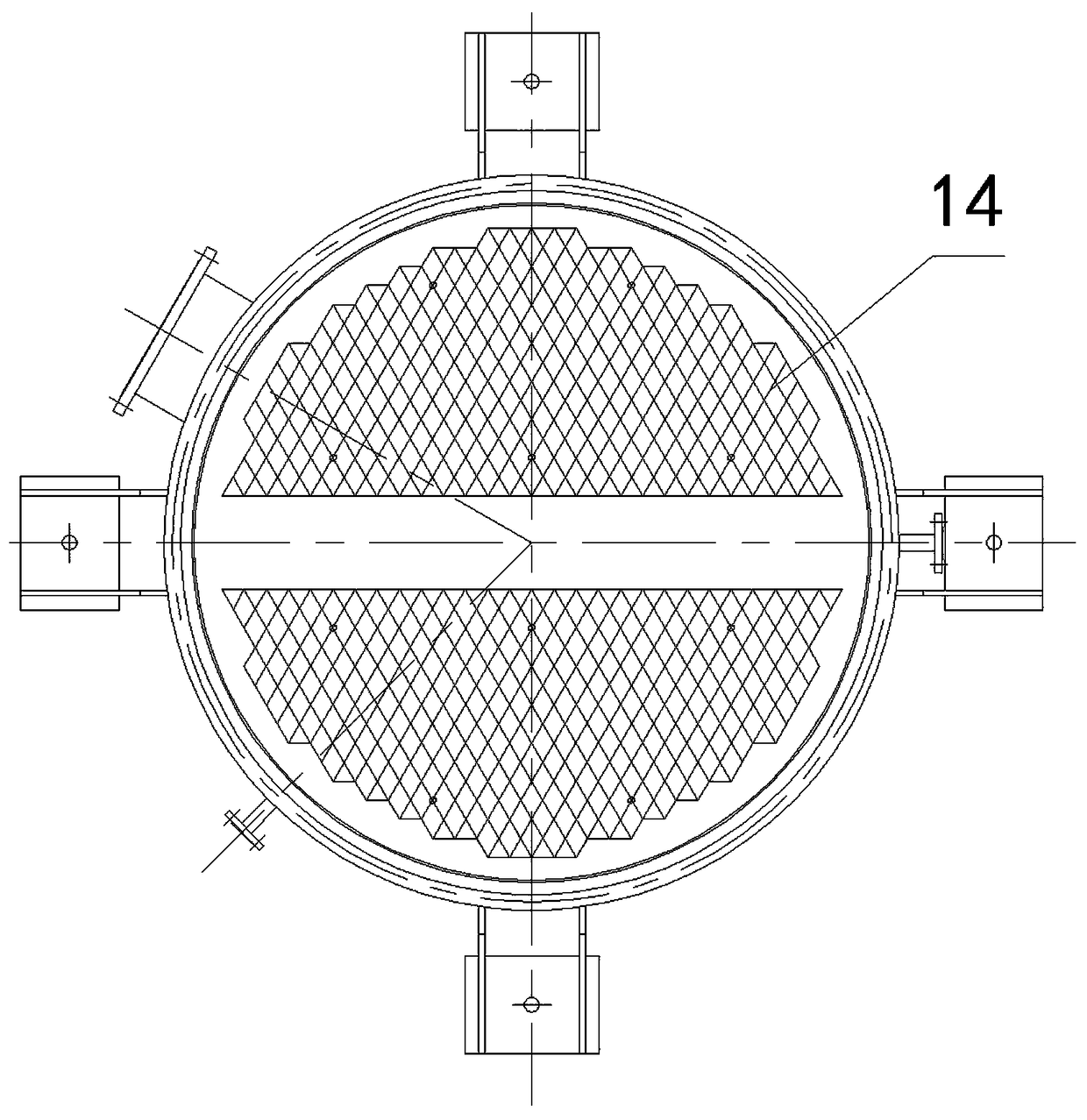

[0020] Such as figure 1 , figure 2 , image 3 As shown, a method for preparing an electronic-grade hydrogen fluoride washing and absorbing device is characterized in that: Step 1, the liquid level conditions of the washing and absorbing tower 1, the circulating storage tank 2, and the condensing tower 4 must be observed through a liquid level gauge before use to ensure that The liquid level is 1000mm away from the inlet duct 7 and the exhaust gas discharge port 16, and 300 mm higher than the outlet of the circulation storage tank 2. Open the exhaust valve of the circulation storage tank 2 to empty a small amount of mixed gas to ensure that the liquid seal is in normal working condition.

[0021] Step 2, the tail gas is introduced through the intake pipe 7, and the temperature of the tail gas is 19-21°C at this time, and flows upward through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com