A kind of underwater bearing and sealing device of water flushing slag mixing machine

A technology of sealing device and underwater bearing, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problem of unreliable sealing of underwater bearings, achieve the effects of reducing equipment maintenance, reducing production costs, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

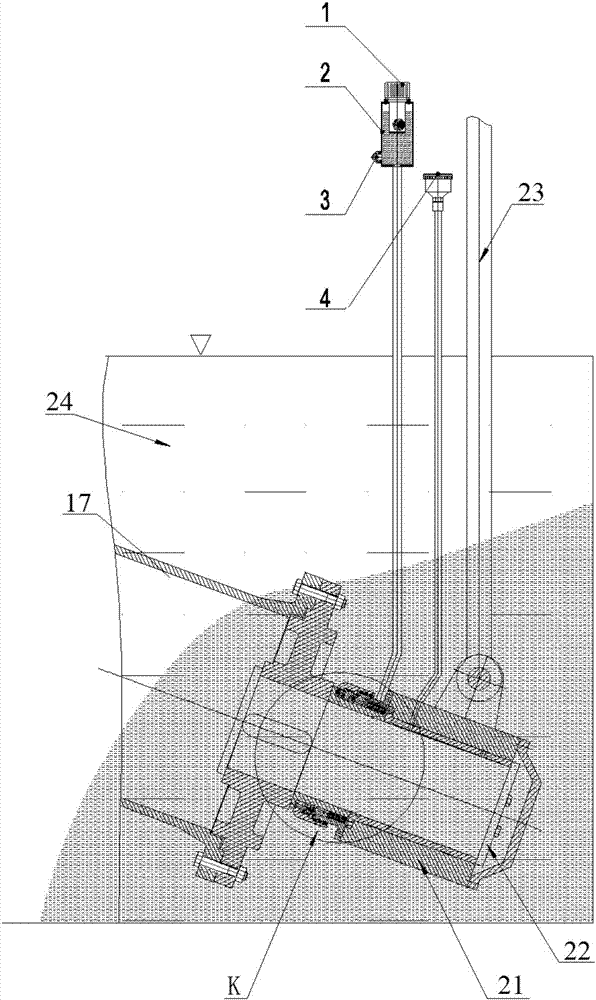

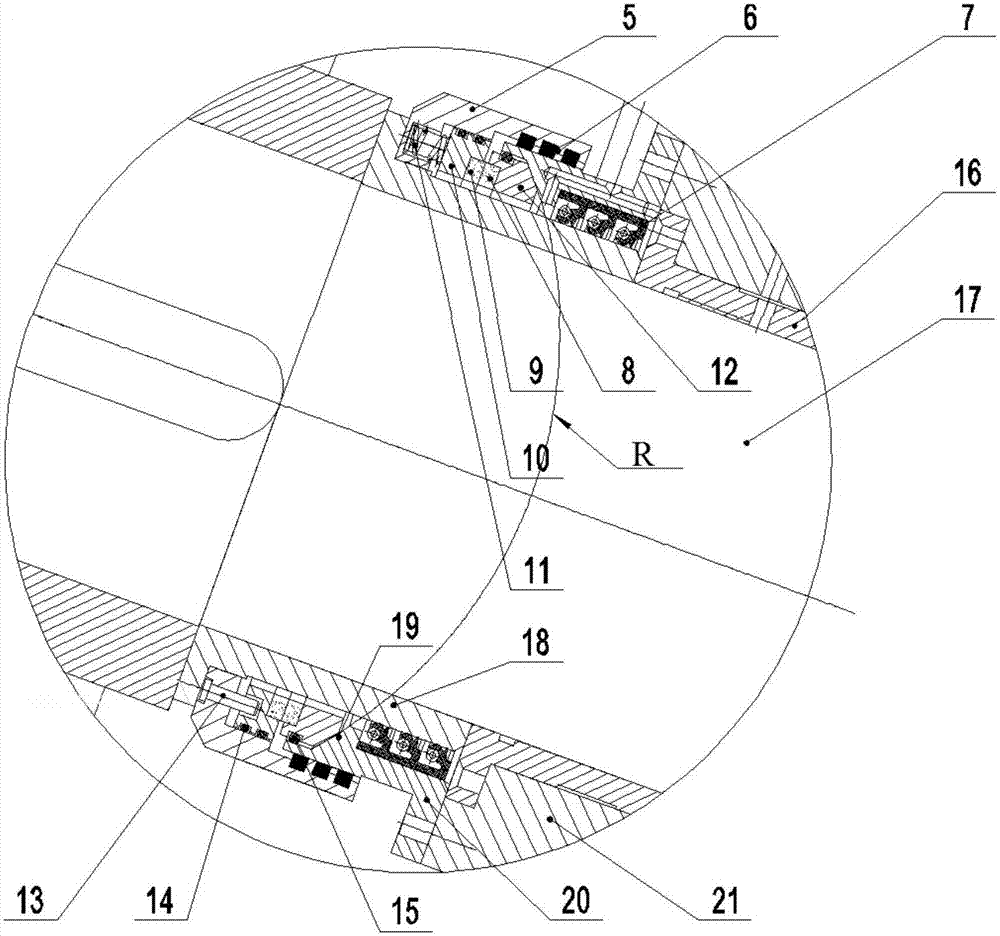

[0038] to combine figure 1 with figure 2, the sealing device of the underwater bearing of a water flushing slag mixing machine in this embodiment includes a three-stage sealing structure and an external oil supply circuit, wherein:

[0039] The first stage is a combined labyrinth seal, including an inverted sealing cup 5, a labyrinth sealing ring 6 and a sealing seat 20. The sealing seat 20 is fixed on the bearing seat 21, and the inverted sealing cup 5 is fixed on the shaft sleeve 18; the shaft sleeve 18 Rotating with the main shaft 17 of the cage stirring machine, the surface of the sealing seat 20 is treated with anticorrosion and hardening. The inner wall of the mouth of the inverted sealing cup 5 is provided with a sealing groove, and the labyrinth sealing ring 6 is embedded in the sealing groove. In this embodiment, three layers of fluorine rubber material labyrinth sealing rings 6 are arranged at the mouth of the cup, and the labyrinth sealing ring 6 will The gap bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com