Handling equipment and safety stopping device thereof

A technology for stoppers and handling equipment, applied to storage devices, transportation and packaging, conveyor control devices, etc., can solve problems such as damage to goods or vehicles, and achieve the effect of enhancing safety measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

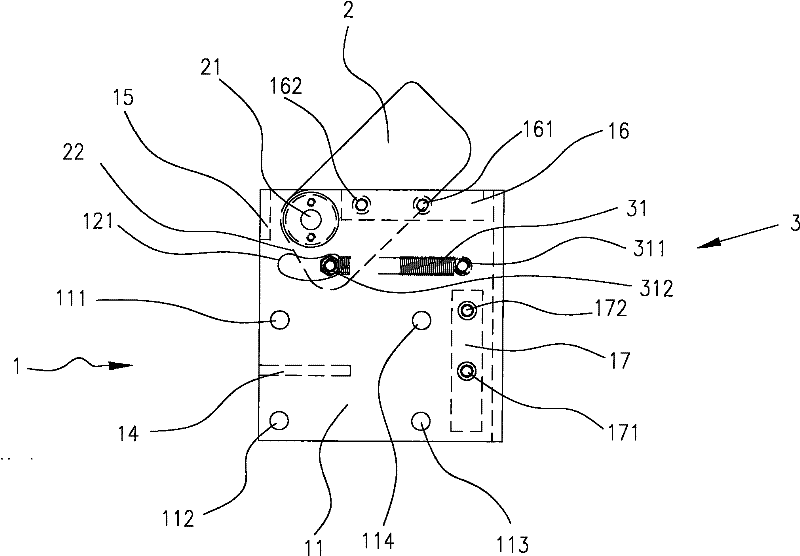

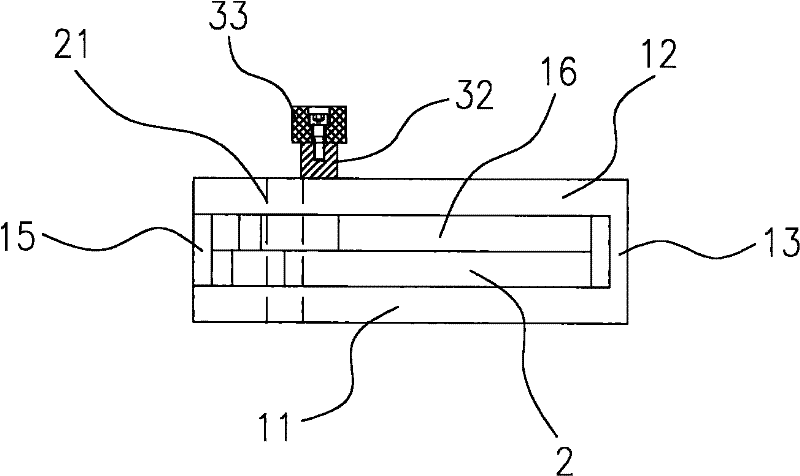

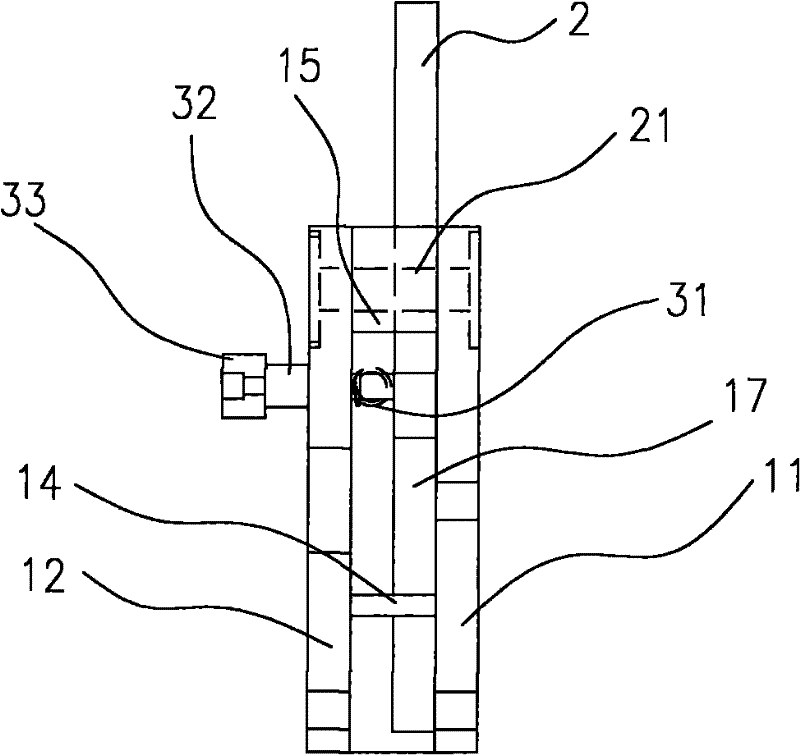

[0025] Figure 1-3 It is a structural schematic diagram of the first embodiment of the safety stop device of the present invention. As shown in the figure, the safety stop device includes: a mounting base 1, a baffle plate 2 hinged on the mounting base 1 and a a drive mechanism 3 . The installation seat 1 includes: two panels 11 , 12 and a connecting plate 13 connected between the two panels 11 , 12 . Holes 111 , 112 , 113 , 114 are opened on the panels 11 , 12 , and the safety stopper is installed on the handling equipment through the holes 111 , 112 , 113 , 114 . The two panels 11 , 12 and the connecting plate 13 form a U-shape with one side open, so as to form a cavity for accommodating the baffle 2 between the two panels 11 , 12 . Reinforcement plates 14 , 15 are respectively mounted on the upper and lower parts between the two panels 11 , 12 near the open side (that is, the side away from the connecting plate 13 ), so as to enhance the strength of the mounting base 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com