Electromagnetic damping shock absorber

A technology of electromagnetic damping and shock absorber, applied in the direction of shock absorber, shock absorber, shock absorber-spring combination, etc. Reduced coercive force requirements, optimized damping coefficient, and better vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

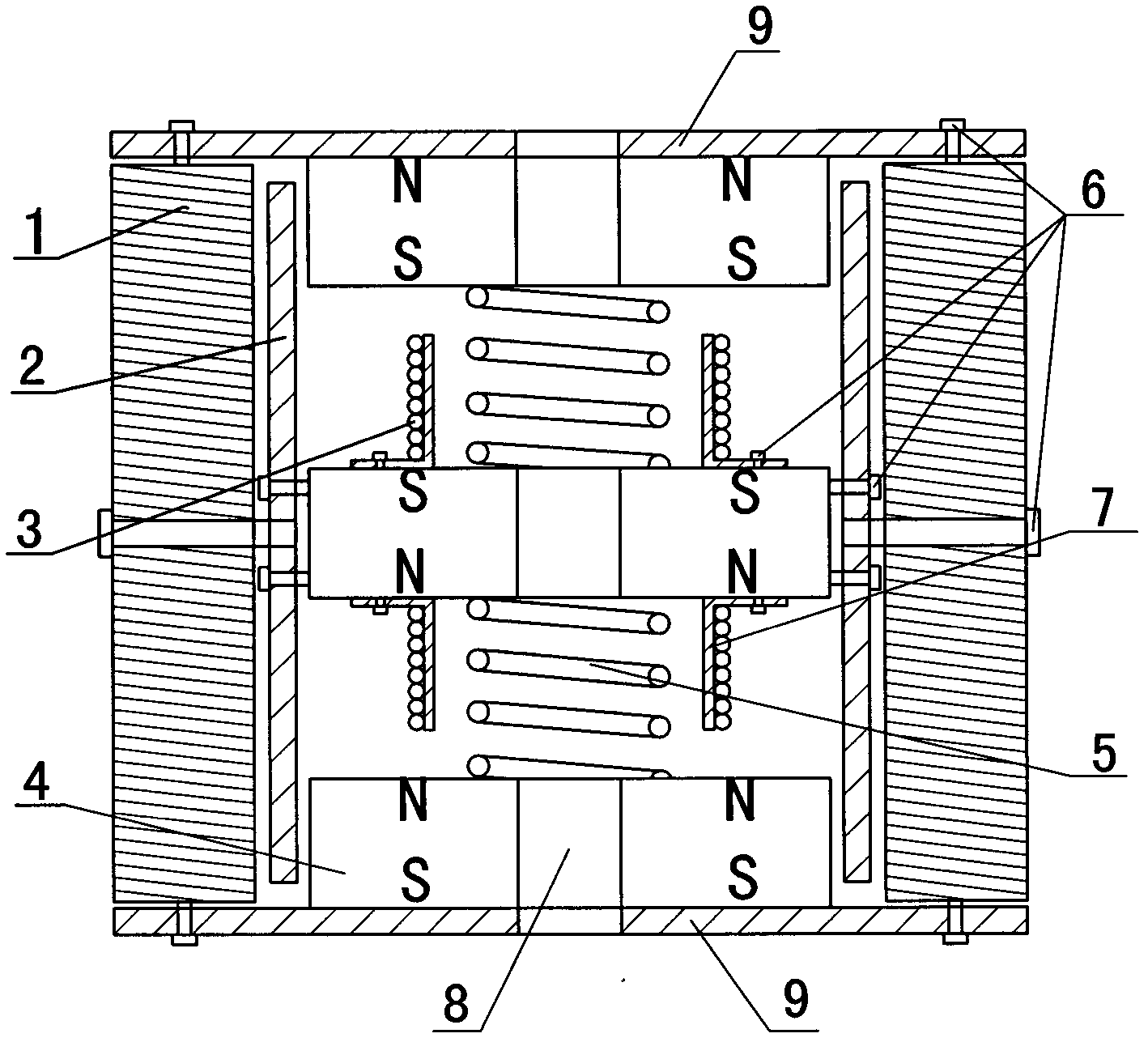

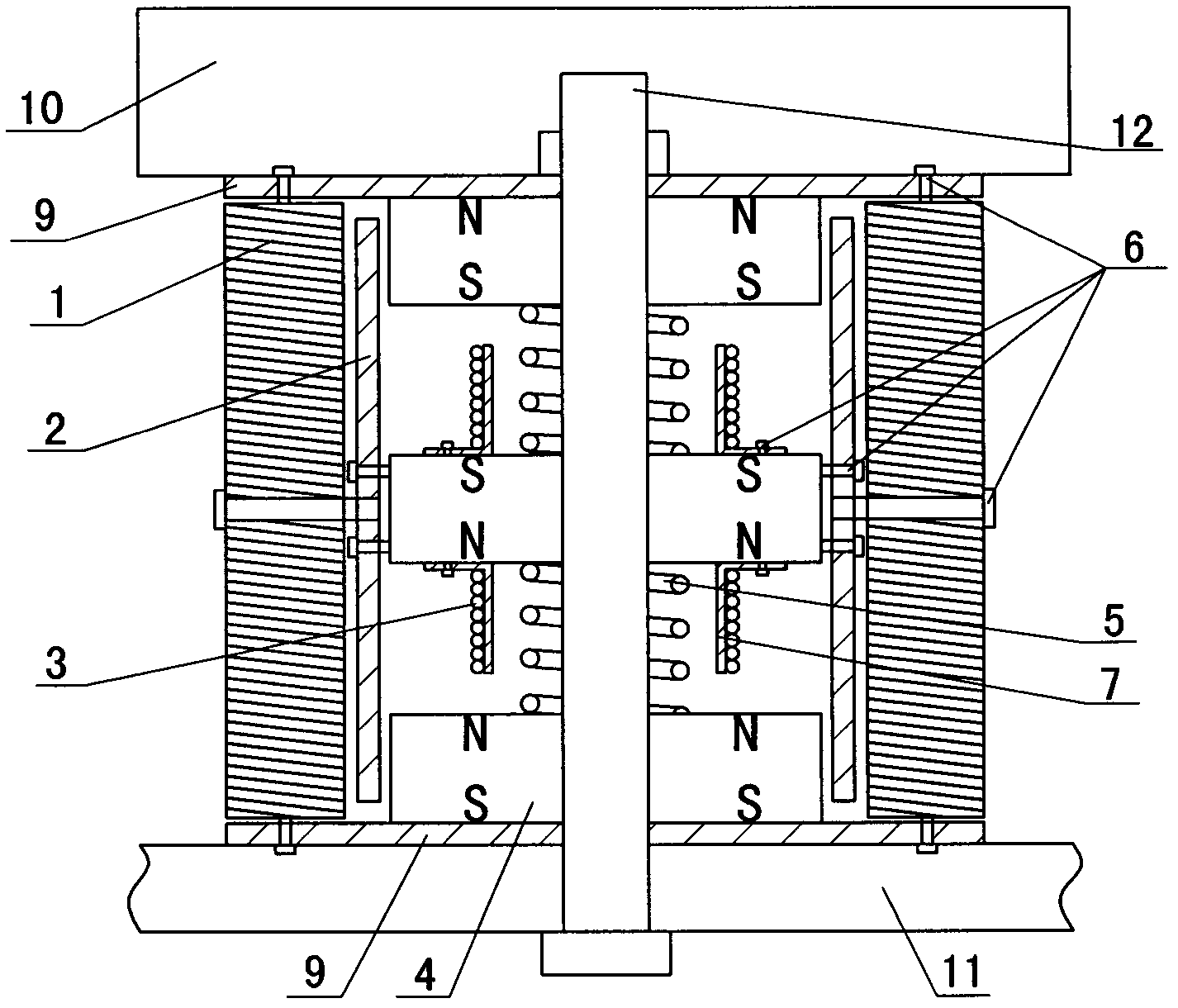

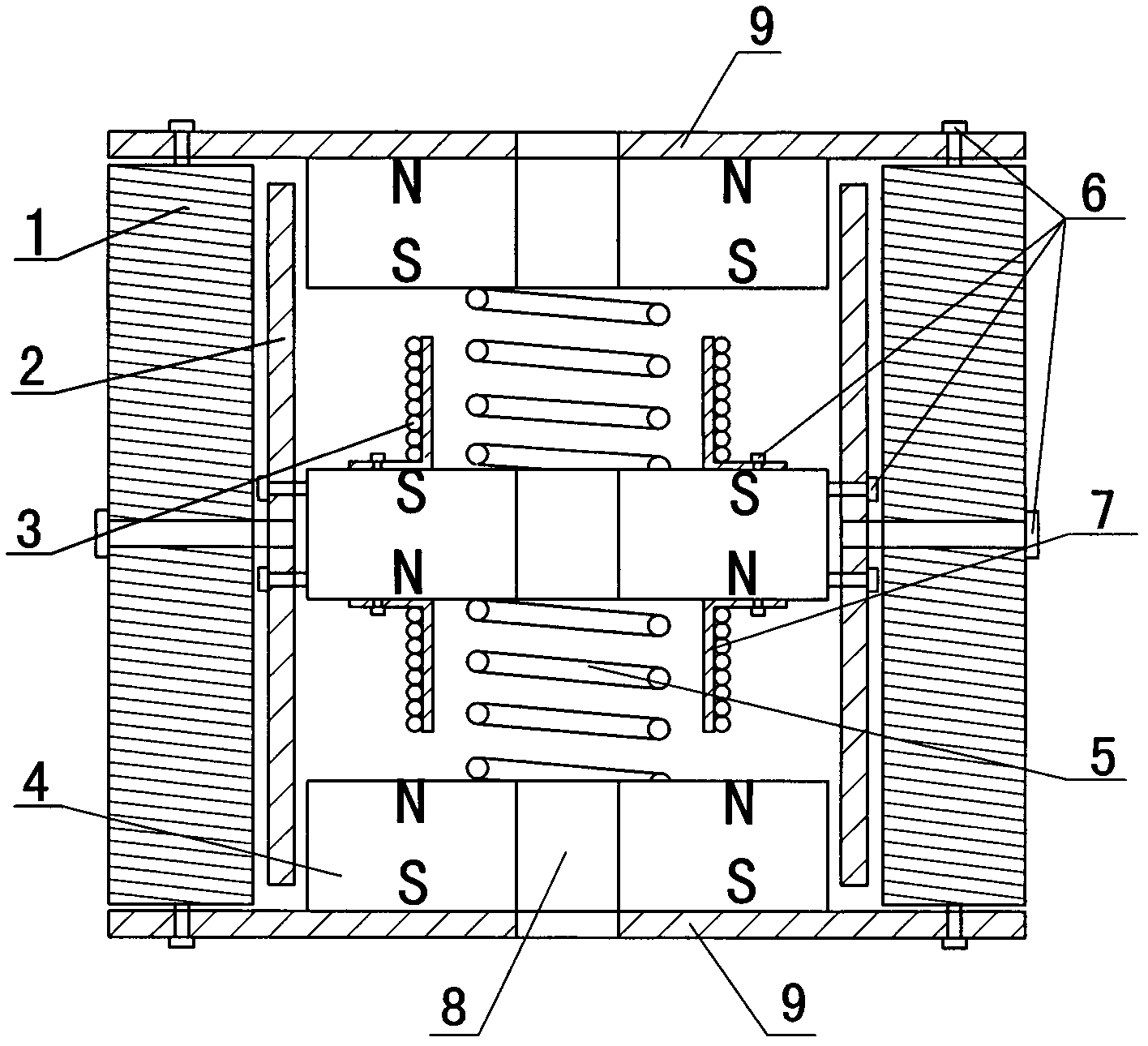

[0015] exist Figure 1-2 In the shown embodiment: rubber shock absorber 1 with openings at both ends, metal antimagnetic round tube 2 fitted and fixed in rubber shock absorber 1, and metal antimagnetic round tube 2 placed in the metal antimagnetic round tube 2 from top to bottom Three permanent magnets 4 and the spring 5 that are press-fitted between the permanent magnets 4, wherein the two open ends of the rubber shock absorber 1 are fixed with an end cover 9, and the two ends of the metal antimagnetic circle have a certain gap from the end cover 9; The adjacent ends of the adjacent permanent magnets 4 have the same magnetism, and the permanent magnet 4 in the middle is fixedly connected with the metal anti-magnetic round pipe 2 through the bolt 6. The upper and lower end faces of the permanent magnet 4 are fixed with a coil support 7, and the closed The induction coil 3 is wound on the coil support 7, and neither the coil support 7 nor the induction coil 3 touches the adjace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com