Electrostatic spraying array system and optimizing method thereof

A technology of electrostatic spraying and optimization method, which is applied in the direction of spraying device, spray discharge device, etc., which can solve the problems of complex inefficiency, low deposition speed, and the spraying area cannot be completely covered and overlapped.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

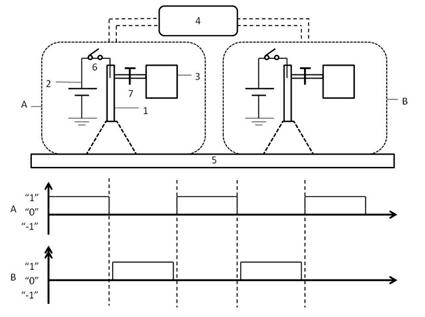

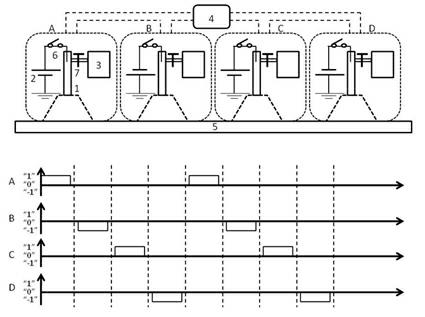

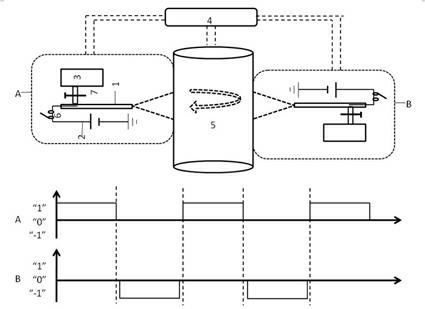

[0020] As shown in the figure, an electrostatic spraying array containing two or more electrostatic spraying units, each electrostatic spraying unit may include some or all of the following devices: an electrostatic spraying nozzle 1, a charge generation and injection device 2 , a liquid storage and transport device 3, an automatic control device 4 for realizing a specific switching pattern, a jetting substrate 5, a switch 6 for controlling the charge generation or injection path, and a switch for controlling the liquid storage or transport path 7. Different electrostatic spraying units can be independent from each other or can share some devices or be part of each other; the devices can be physically separated or have no clear boundaries; some devices can be omitted according to the situation; and so on.

[0021] The typical form of nozzle 1 is tubular, or capillary, cavity, surface with raised points or other shapes that can realize electrostatic spraying; the liquid sprayed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com