Stamping device for inner strap

A technology of punching device and inner strap, applied in the application, belt, household appliances and other directions, can solve the problems of reduced productivity, increased maintenance and management costs, large economic burden, etc., and achieve the effect of improving productivity and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The advantages, features, and methods for realizing the present invention will become more apparent with reference to the drawings and the embodiments described later.

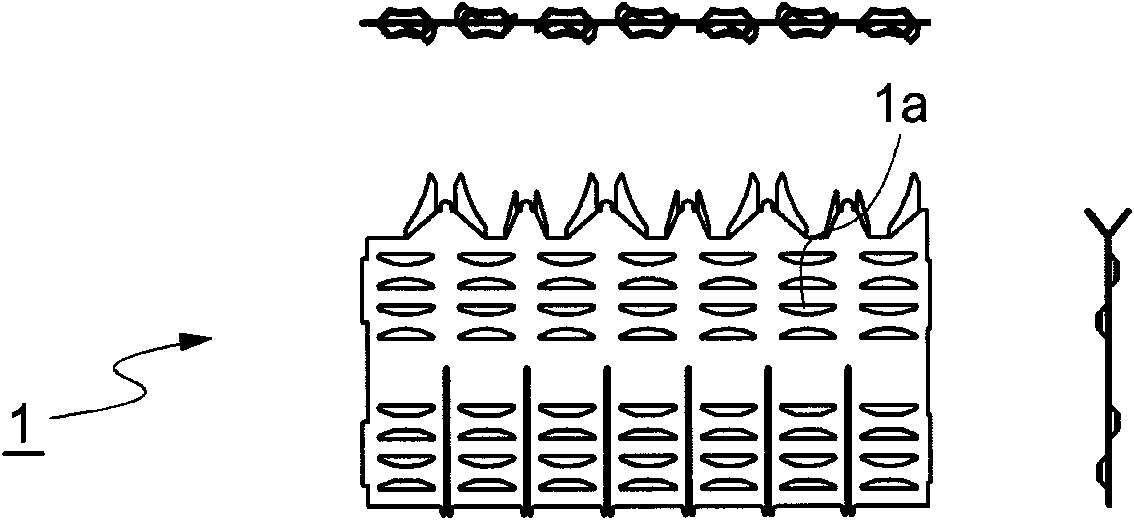

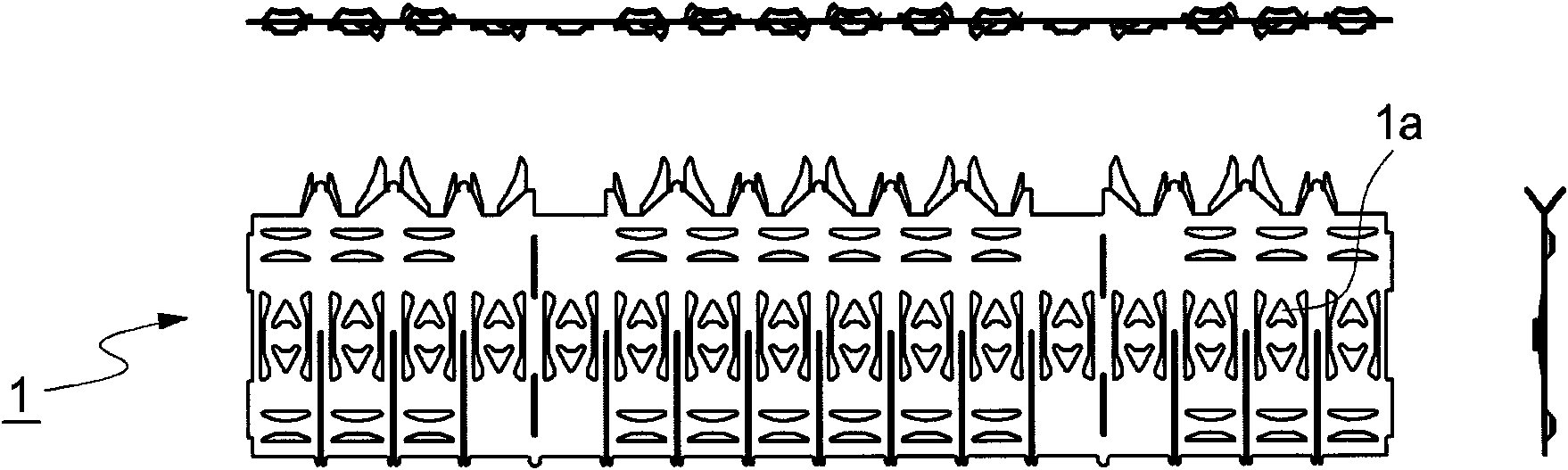

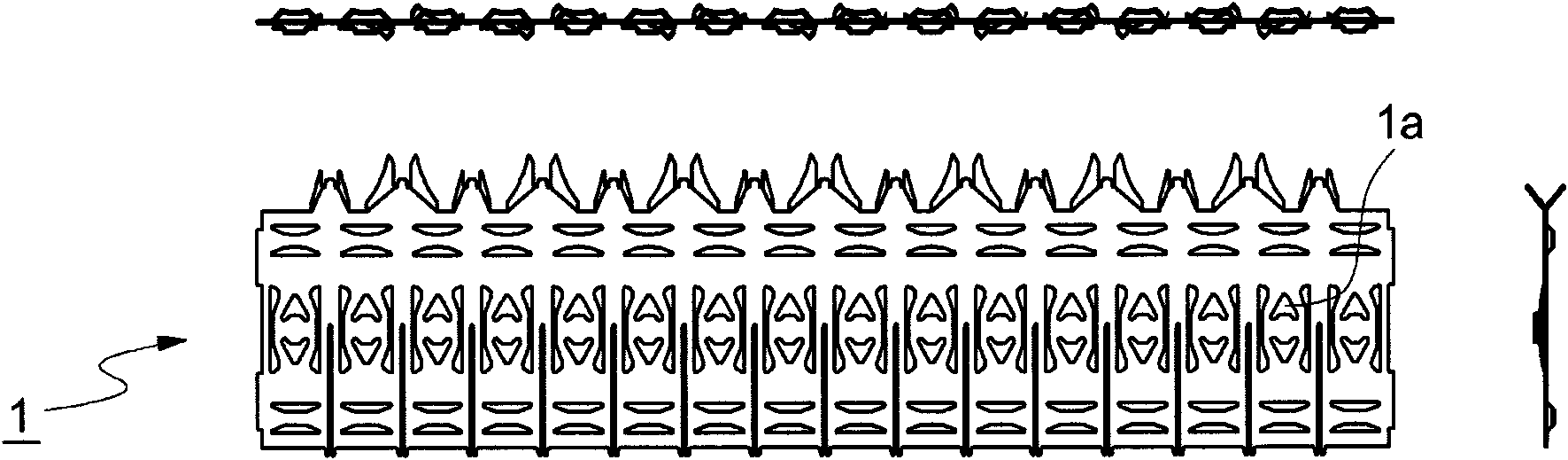

[0034] Figure 4 It is a schematic diagram of the press apparatus of this invention. Figure 5 It is a plan view of the lower die of the press device of the present invention. Figure 6 is a flow chart of making inner strips with the punching device of the present invention. Figure 7 It is a structural diagram of the connection part of the press apparatus of this invention, and it is a state diagram before operation. Figure 8 It is a structural diagram of the connection part of the press apparatus of this invention, and it is a state diagram after operation. Figure 9 It is a block diagram of the second supply part of the press apparatus of this invention, and it is a state diagram before operation. Figure 10 It is a structural diagram of the second supply part of the press apparatus of this inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com