Method for improving internal quality of continuous casting and submerged nozzle for implementing method

An internal quality, immersion technology, used in casting equipment, casting melt containers, manufacturing tools, etc., can solve the problems of insignificant effect and limited addition, and achieve improved internal quality, reduced center segregation, and improved center porosity. The effect of shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

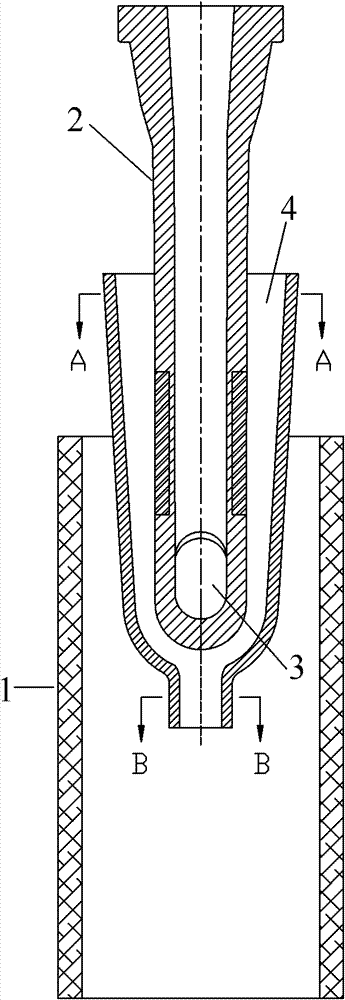

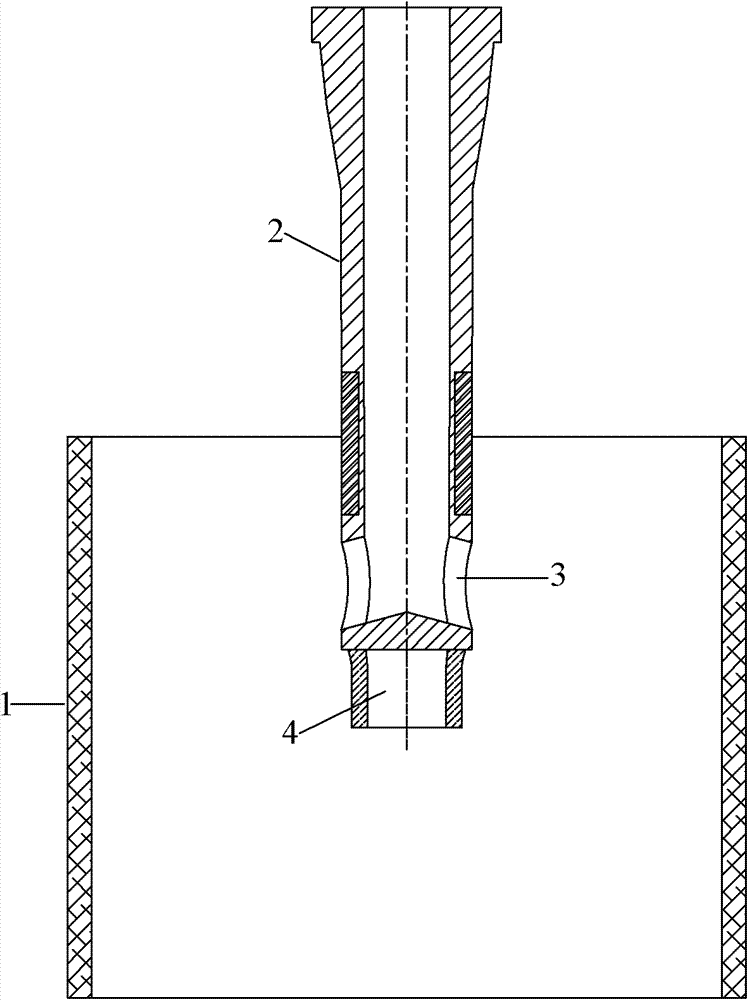

[0028] Attached below Figure 1-4 The method and apparatus of the present invention are further described.

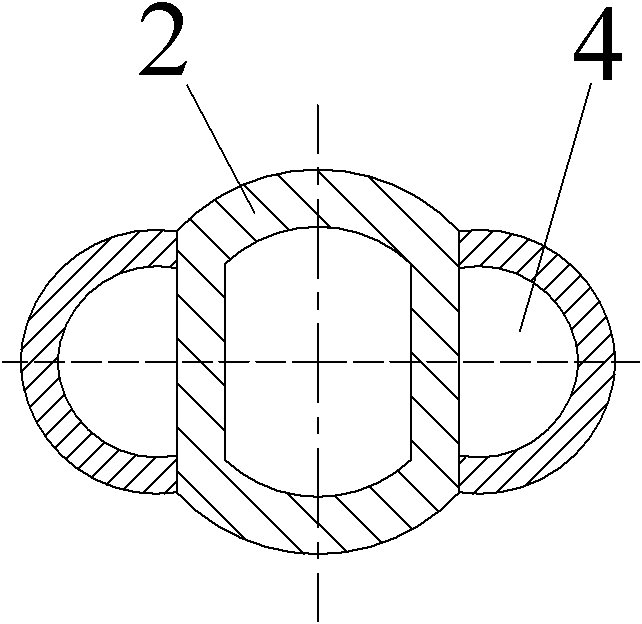

[0029] Such as Figure 1-4 As shown, the submerged nozzle device adopted in the present invention mainly includes a nozzle body 2, and two side holes 3 symmetrical along the center line of the nozzle are opened on the bottom of the nozzle body 2. Feeding conduits 4 are arranged on the opposite parallel sides of the openings 3 on the nozzle body 2, and the feeding conduits 4 are integrated with the nozzle body 2, and its width is substantially equal to the width of the connected nozzle wall, and the shape can be Square, semicircular or flat.

[0030] For the convenience of adding materials, the hollow surfaces on each side of the feeding conduit 4 are at an inclination angle of 5°-60° to the vertical direction, and the distance between the opening of the feeding conduit 4 and the top surface of the crystallizer 1 is 200mm-600mm. The feeding conduits 4 on both sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com