Screen printing plate and manufacturing method thereof

A technology for screen printing plates and manufacturing methods, which is applied to screen printing machines, printing machines, printing machines, etc., and can solve problems such as misalignment, increased manufacturing costs of screen printing plates, and lengthened plate-making processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

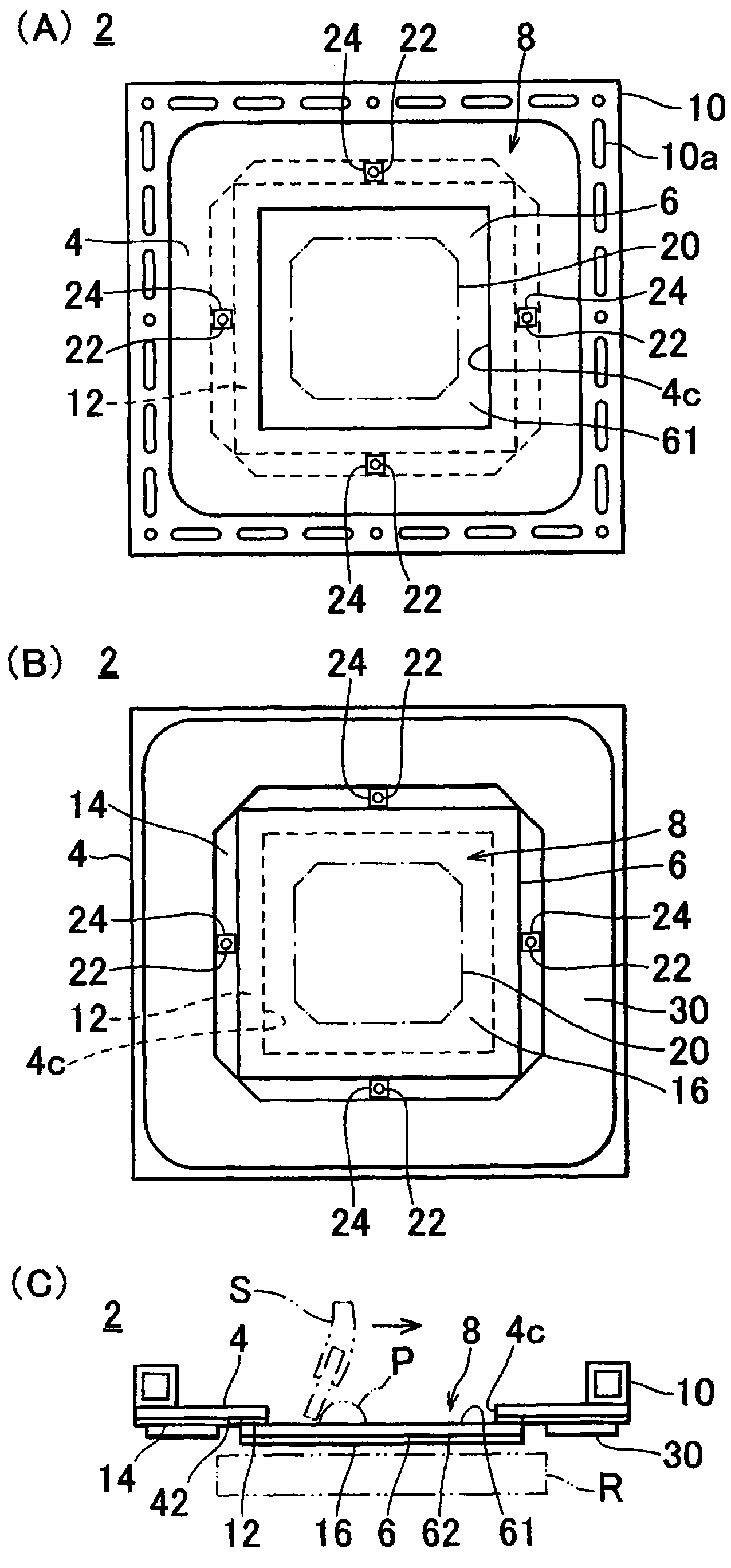

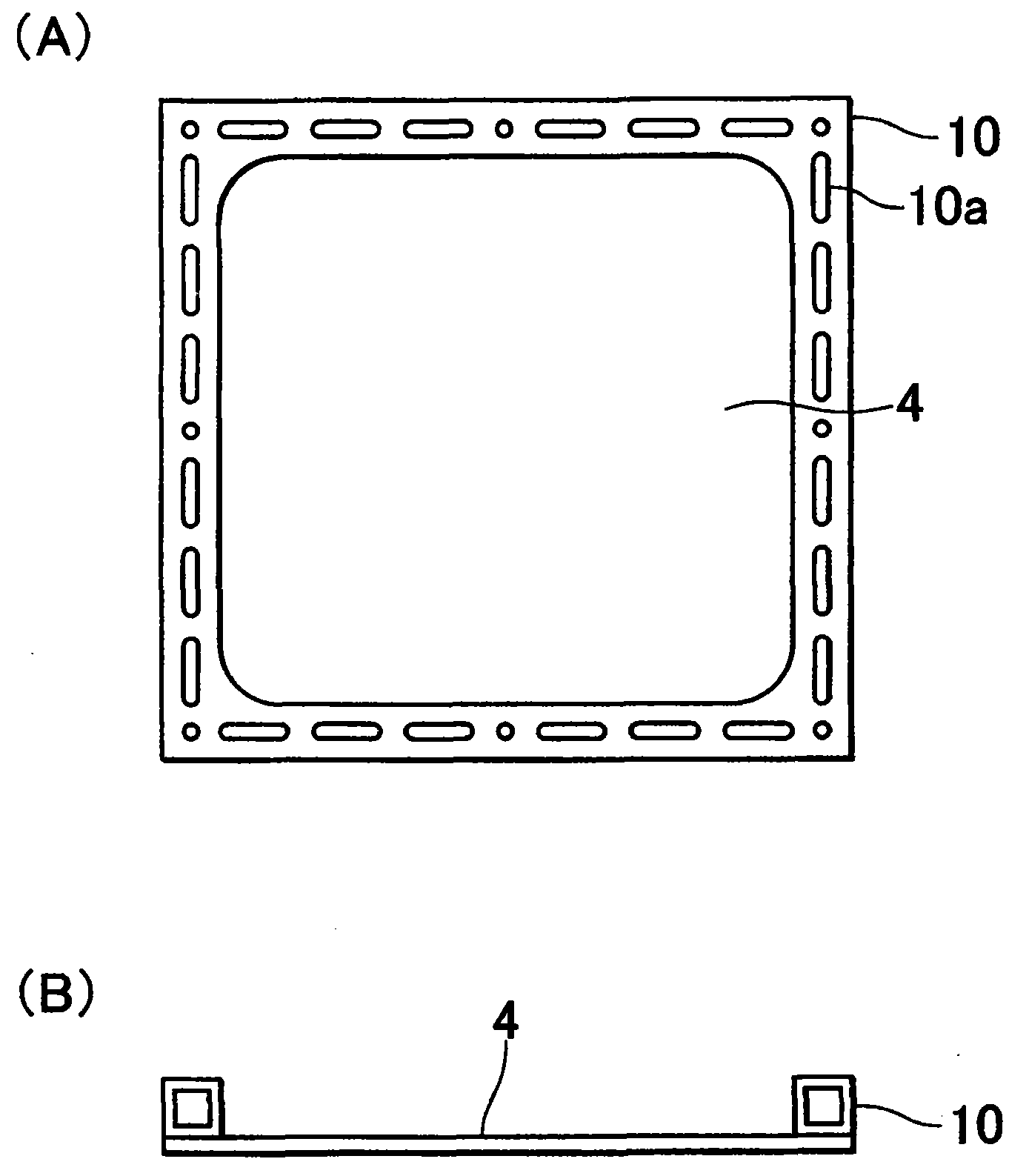

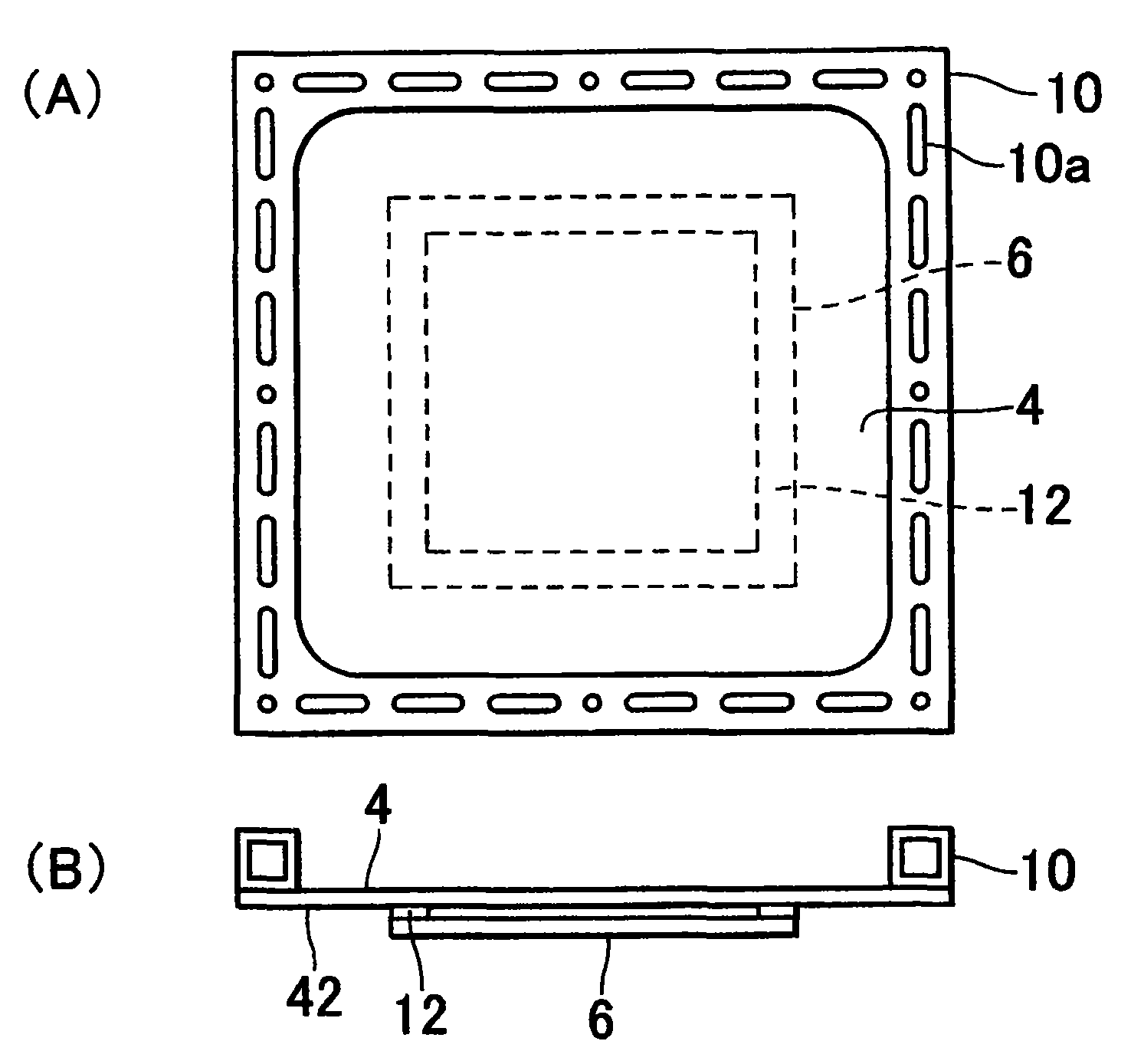

[0034] One embodiment of the screen printing plate of the present invention will be described. figure 1 (A) is a plan view showing the screen printing plate 2, figure 1 (B) is the rear view, figure 1 (C) is a schematic process diagram. The screen printing plate 2 basically includes: a screen body 8 having a combined structure of an outer yarn 4 and an inner yarn 6 ; and a frame 10 in the form of a picture frame.

[0035] The picture frame-like frame 10 whose overall shape is rectangular is made of aluminum or stainless steel, and has a rectangular cylindrical cross-section to reduce weight and mechanical deformation, and has long holes 10a formed at predetermined intervals.

[0036] The outer yarn 4 is composed of a rectangular resin net, and is bonded with an adhesive by a normal (Nomal) pasting method (a method in which the fiber direction of the pasted resin net is parallel to the direction of the picture frame stencil 10 and pasted). Paste directly on the picture fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com