Steel bar and joint of steel bar

A technology of steel bars and reinforced concrete, applied in the direction of structural elements, building components, building reinforcements, etc., to achieve the effect of suppressing interference and low height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

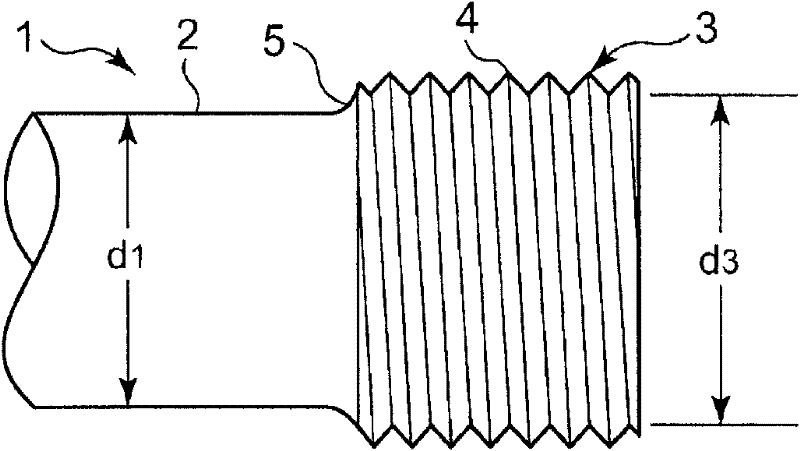

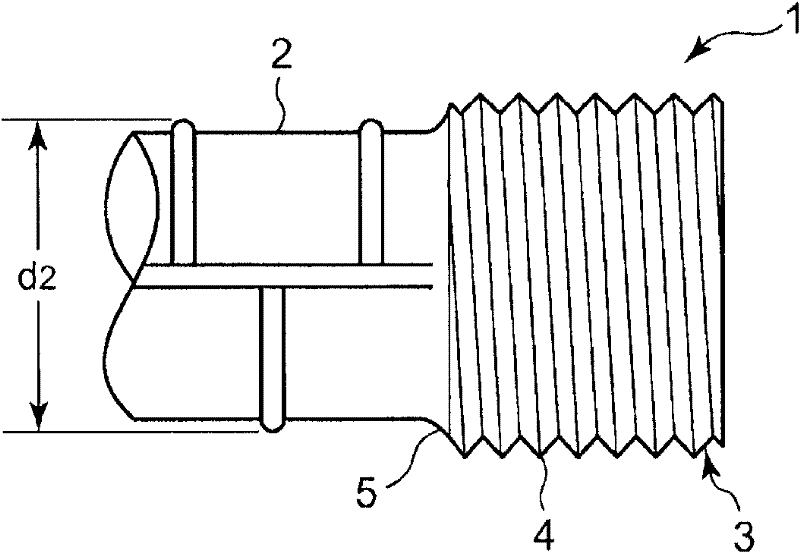

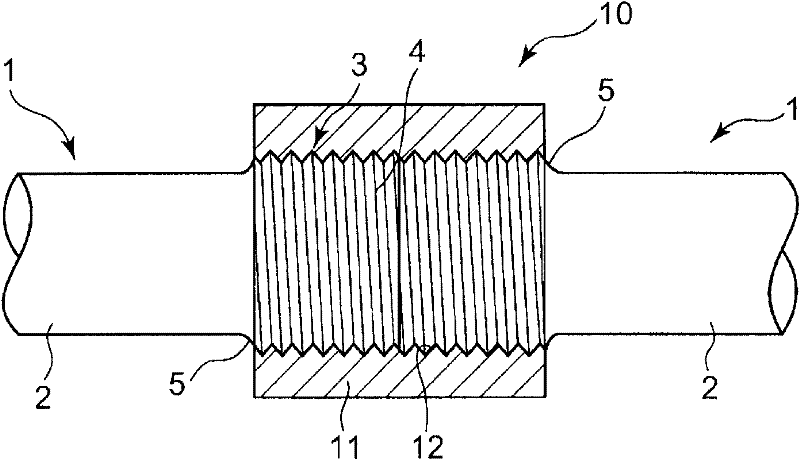

[0025] Next, one embodiment of a reinforcing bar and a reinforcing bar joint in the present invention will be described based on the drawings. Such as figure 1 As shown, the steel bar 1 of an example of this embodiment is used as the main bar of the beam or column which becomes a reinforced concrete, and the threaded part 3 is formed in the end part. That is, the reinforcing bar 1 of this embodiment is provided with the reinforcing bar main body 2 and the threaded part 3 . The steel bar 1 (that is, the steel bar body 2) is not particularly limited as long as it is used as the main bar of a reinforced concrete beam or column. (The common name of the steel bar is D25), the diameter is 28.6mm (the common name of the steel bar is D29), the diameter is 31.8mm (the common name of the steel bar is D32), the diameter is 34.9mm (the common name of the steel bar is D35), the diameter is 38.1mm (the common name of the steel bar is D38) ), steel bars with a diameter of 41.3mm (commonly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com