Method for extracting and separating silver by double-aqueous phase system

An aqueous two-phase system and extraction technology, applied in the field of analytical chemistry, can solve problems such as reports of no extraction and separation of silver, and achieve the effects of avoiding toxic reagents, high extraction rate and little interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

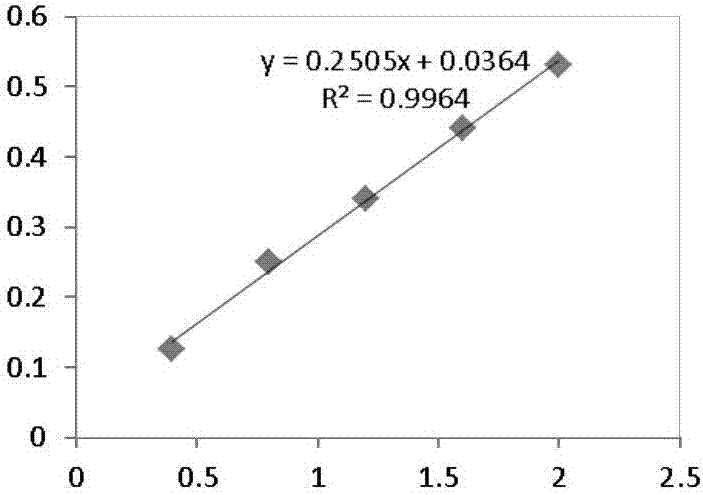

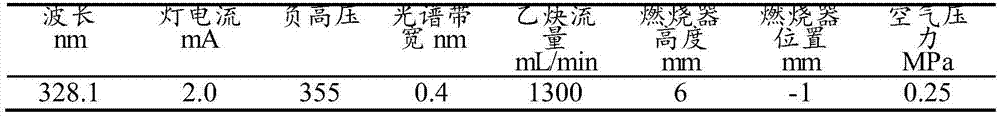

Method used

Image

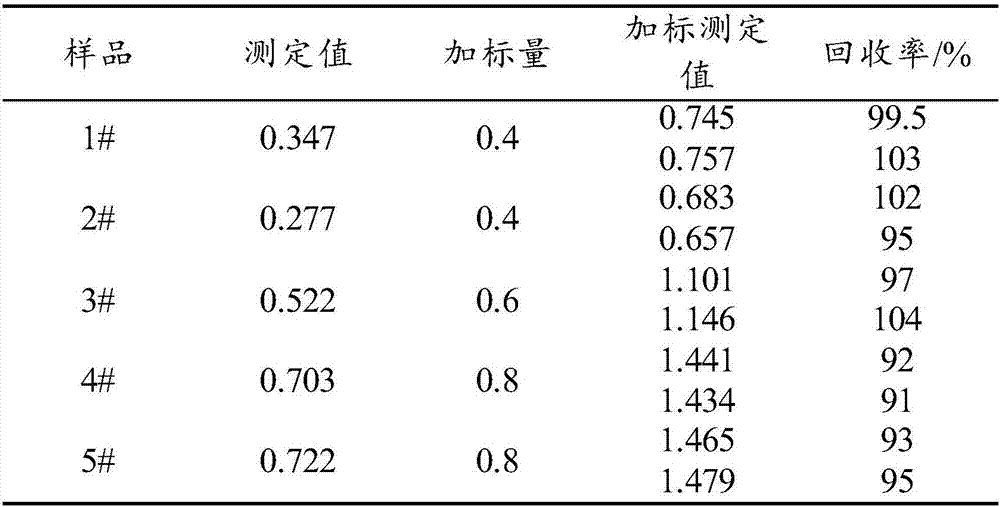

Examples

Embodiment 1

[0052] In a 15mL plastic colorimetric tube, add 0.20mL of Ag-containing + solution, 1mL0.2mol L -1 KSCN solution, 1.0mL0.001mol L -1 CTMAB solution, 1mL KCl-HCl buffer solution with pH=1, 3mL propanol, dilute to 10mL with water, then add 2.0g (NH 4 ) 2 SO 4 , oscillated for about 1 min, and stood still for 10 min. The solution was divided into two phases of propanol and water, and the propanol phase was located in the upper layer. Record the volume of the upper layer.

[0053] Upper strata propanol solution directly measures absorbance with flame atomic absorption spectrometry of the present invention, utilizes regression analysis method, reads Ag in the solution by instrument software + The concentration is 0.745μg·mL -1 , the volume of the supernatant is 3.0mL, the calculated Ag + The extraction rate is 103%.

Embodiment 2

[0055] In a 15mL plastic colorimetric tube, add 0.30mL of Ag containing + solution, 0.8mL0.3mol L -1 KSCN solution, 1.0mL0.002mol L -1 CTMAB solution, 1mL KCl-HCl buffer solution with pH=2, 3mL propanol, dilute to 10mL with water, then add 2.0g (NH 4 ) 2 SO 4 , oscillated for about 1 min, and stood still for 10 min. The solution was divided into two phases of propanol and water, and the propanol phase was located in the upper layer. Record the volume of the upper layer.

[0056] Upper strata propanol solution directly measures absorbance with flame atomic absorption spectrometry of the present invention, utilizes regression analysis method, reads Ag in the solution by instrument software + The concentration is 0.522μg·mL -1 , the volume of the supernatant is 3.0mL, the calculated Ag + The extraction rate is 97%.

Embodiment 3

[0058] In a 15mL plastic colorimetric tube, add 0.40mL of Ag containing + solution, 0.6mL0.4mol L -1 KSCN solution, 0.2mL0.1mol L -1 CTMAB solution, 1mL KCl-HCl buffer solution with pH=3, 3mL propanol, dilute to 10mL with water, then add 1.8g (NH 4 ) 2 SO 4 , oscillated for about 1 min, and stood still for 10 min. The solution was divided into two phases of propanol and water, and the propanol phase was located in the upper layer. Record the volume of the upper layer.

[0059] Upper strata propanol solution directly measures absorbance with flame atomic absorption spectrometry of the present invention, utilizes regression analysis method, reads Ag in the solution by instrument software + The concentration is 0.703μg·mL -1 , the volume of the supernatant is 3.0mL, the calculated Ag + The extraction rate is 93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com