Ultrasonic resonance frequency matching device

A resonant frequency and matching device technology, applied in the field of ultrasonic cleaning, can solve the problems of high cost, large volume of cleaning equipment, inconvenient operation, etc., and achieve the effect of enhancing the vibration amplitude and improving the effect of crushing or cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, various embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

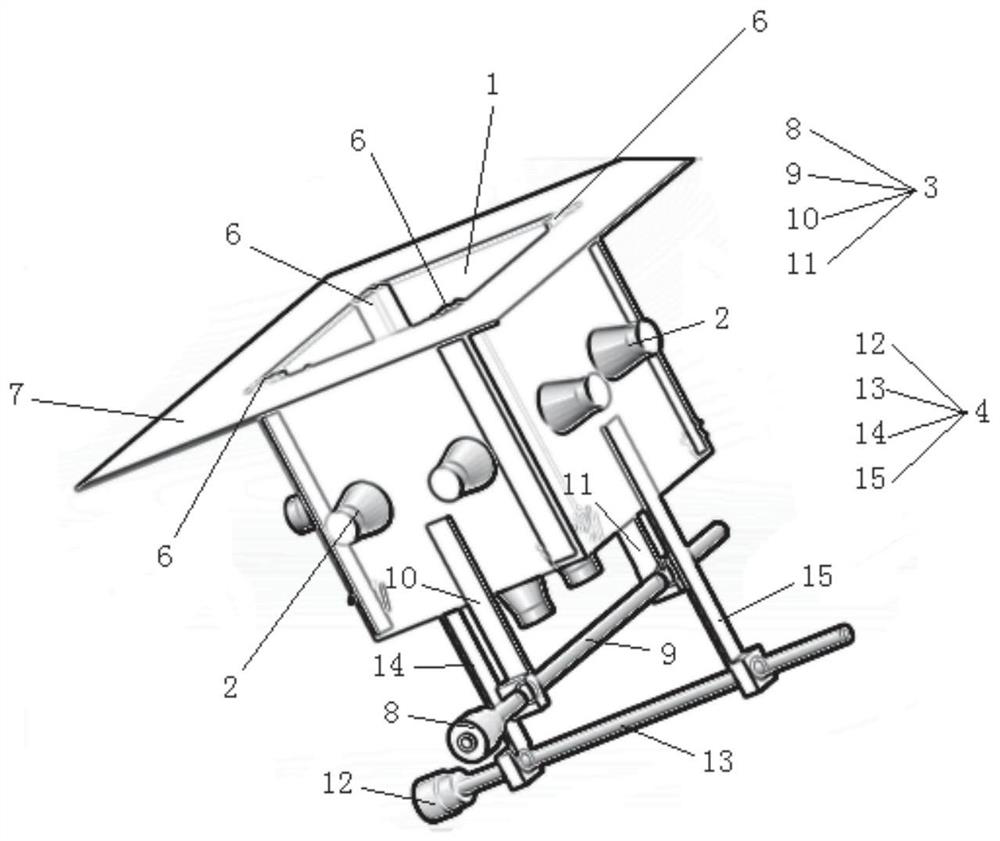

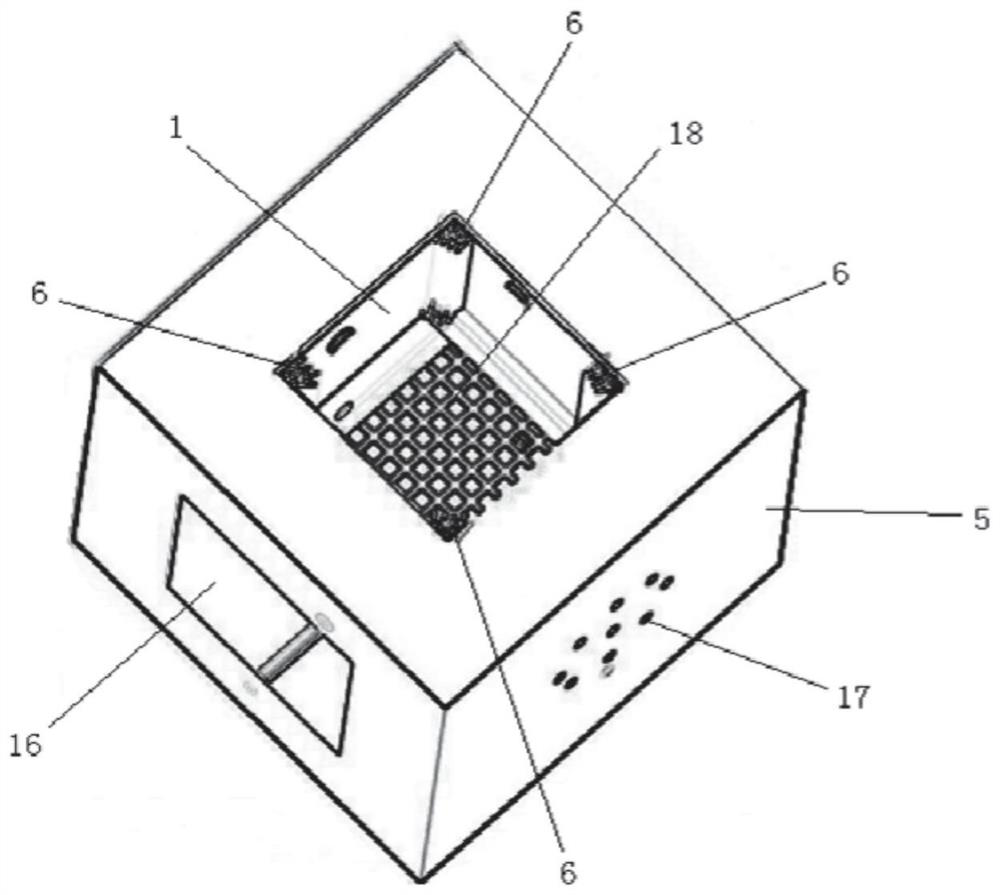

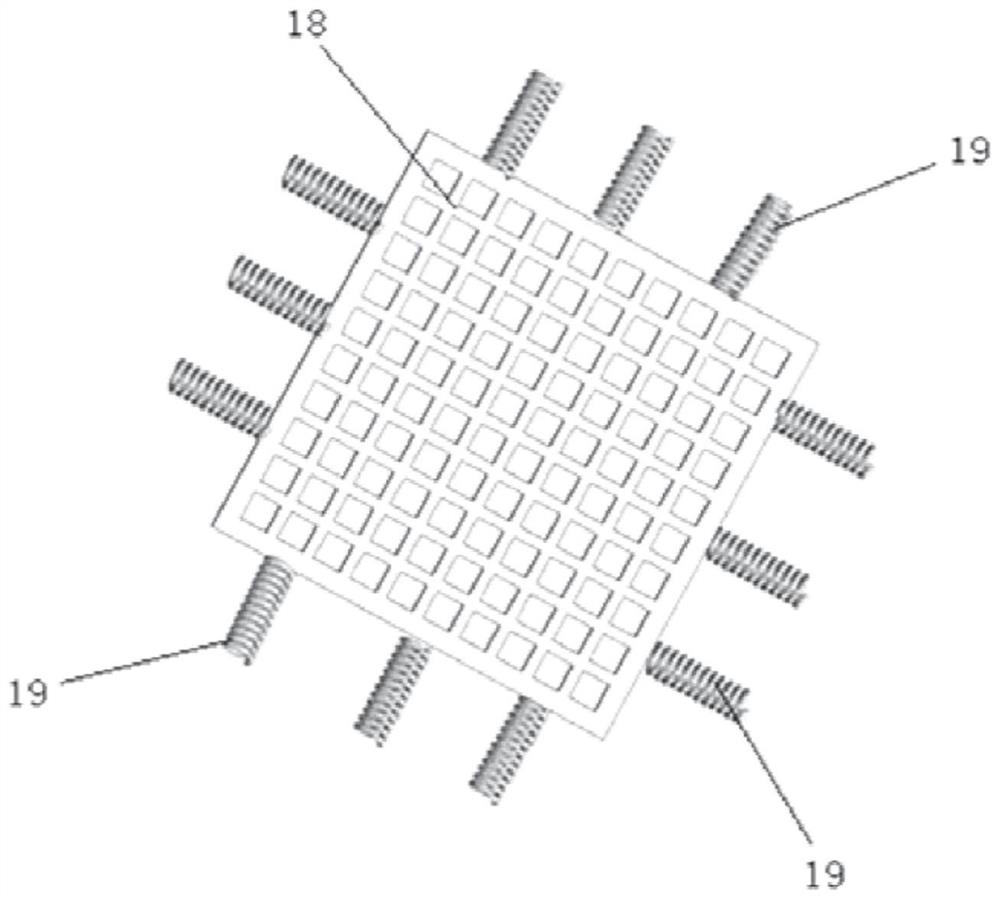

[0033] combine figure 1 and figure 2As shown, an ultrasonic resonance frequency matching device includes a water intake tank 1 , an ultrasonic vibrator 2 , an ultrasonic control circuit, an X-axis driving mechanism 3 , a Y-axis driving mechanism 4 and a housing 5 . The four sides and the bottom surface of the water tank 1 are made of steel plates or other plates suitable for ultrasonic cleaning. A foldable mechanism 6 is provided at the junction of the four sides and the bottom surface. The foldable mechanism 6 can be unfolded or folded. The water tank 1 can be The expansion or folding of the foldable mechanism 6 changes the volume size, that is, changes the length and width of the water intake tank 1. The foldable mechanism 6 is sealed with the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com