Thread plug-in type electronic control hydraulic lock

An electronically controlled hydraulic and screw-insert technology, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of low control response flexibility, difficult system integration, complicated installation, etc., and achieve the overall structure Compactness, low overall cost and low maintenance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

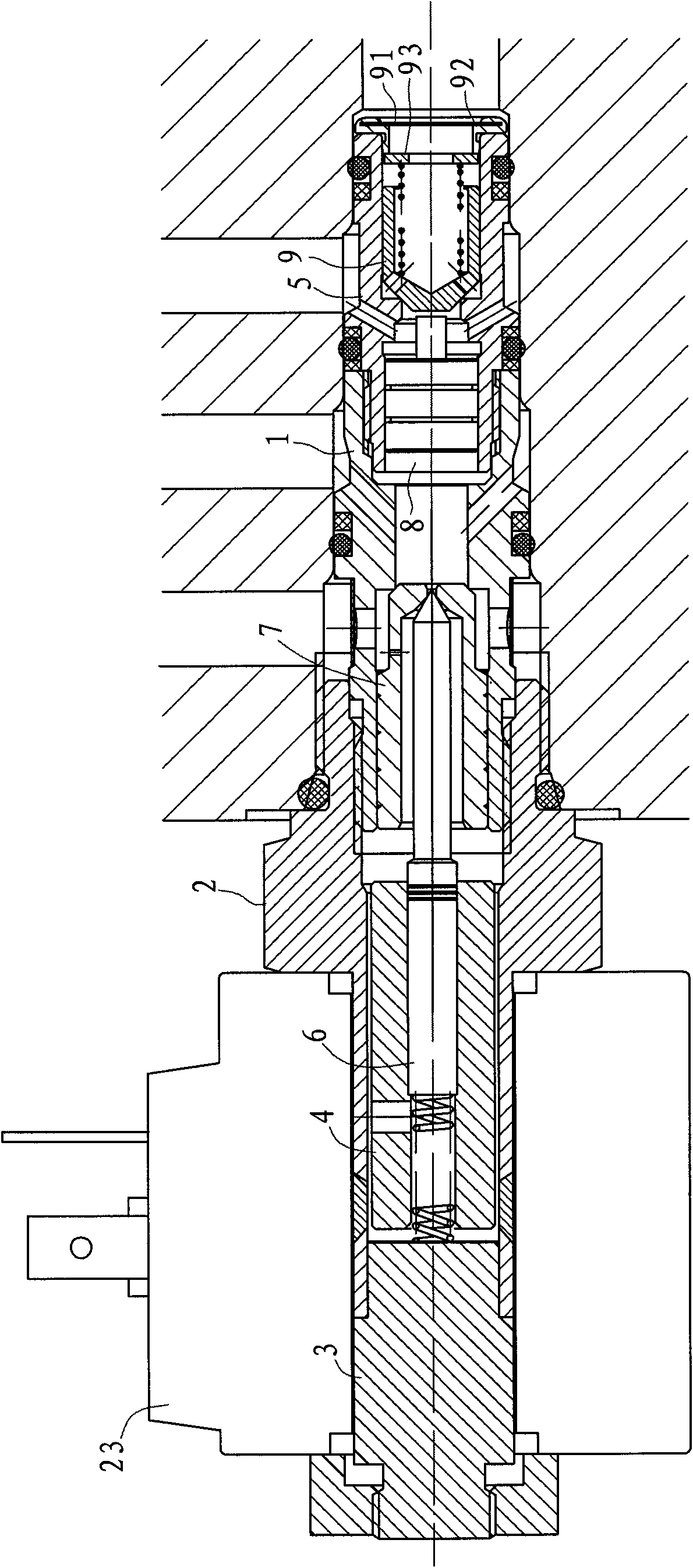

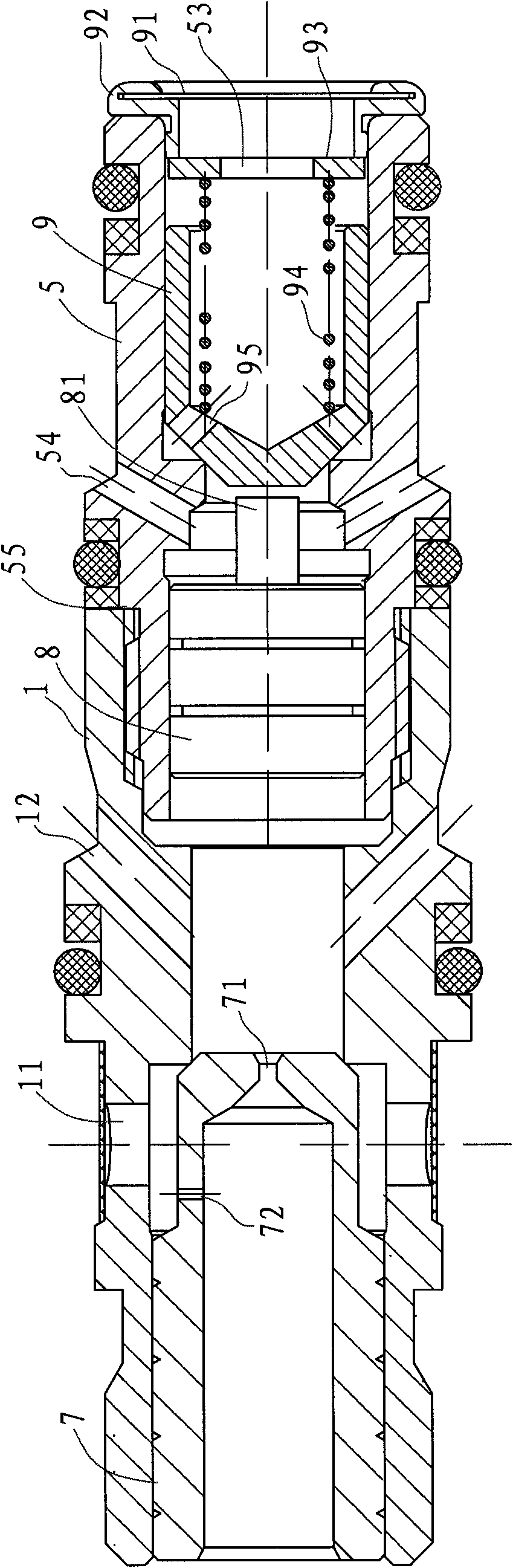

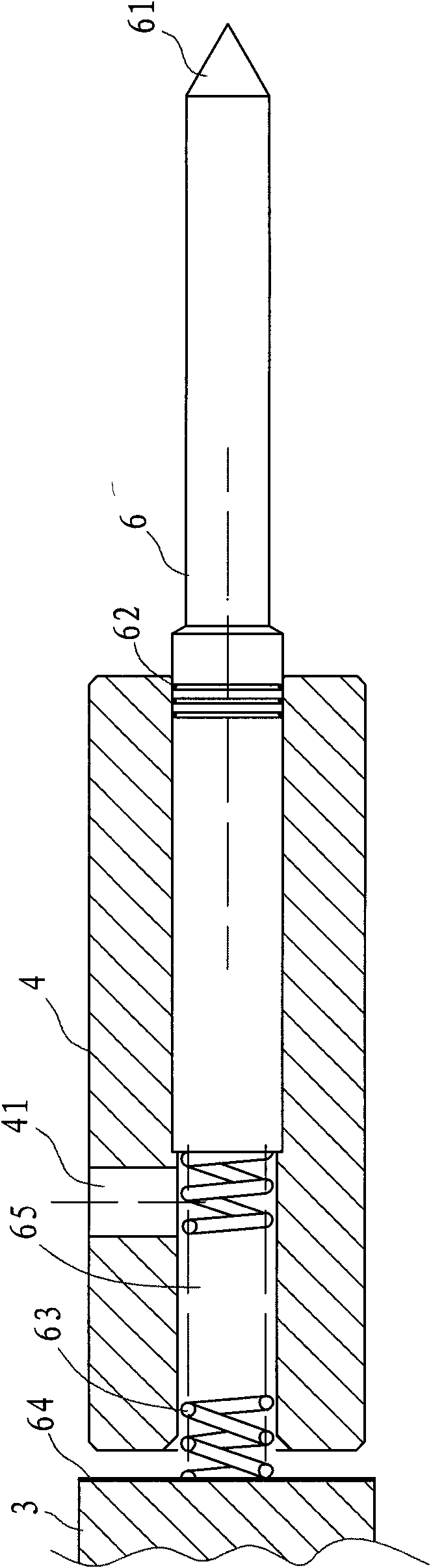

[0028] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the threaded plug-in electronically controlled hydraulic lock in this embodiment includes a magnetic sleeve 2, a fixed iron 3, a moving iron 4, a coil 23, a first reset member 63, a main spool 7, a pilot spool 6, a valve Cover 5, piston 8, valve seat 1, one-way valve core 9, second reset member 94, spring seat 93 and filter screen seat 92.

[0029] The magnetic sleeve 2 is hollow to form an inner cavity, including the body 21 and the extension tube 22 extending backward from the body 21. The fixed iron 3 is arranged at the rear end of the extension tube 22, and the coil 23 is wrapped on the outside of the aforementioned fixed iron and the extension tube. The fixed iron can generate a magnetic field that attracts the moving iron to move backward, and the first reset mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com