Automatic electrostatic discharge detection system

An electrostatic discharge and automatic technology, applied in the direction of electromagnetic field characteristics, etc., can solve the problems of complicated wiring, marked grouped lines, old and rusted lines, etc., to achieve the effect of improving time and safely protecting electrostatic discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

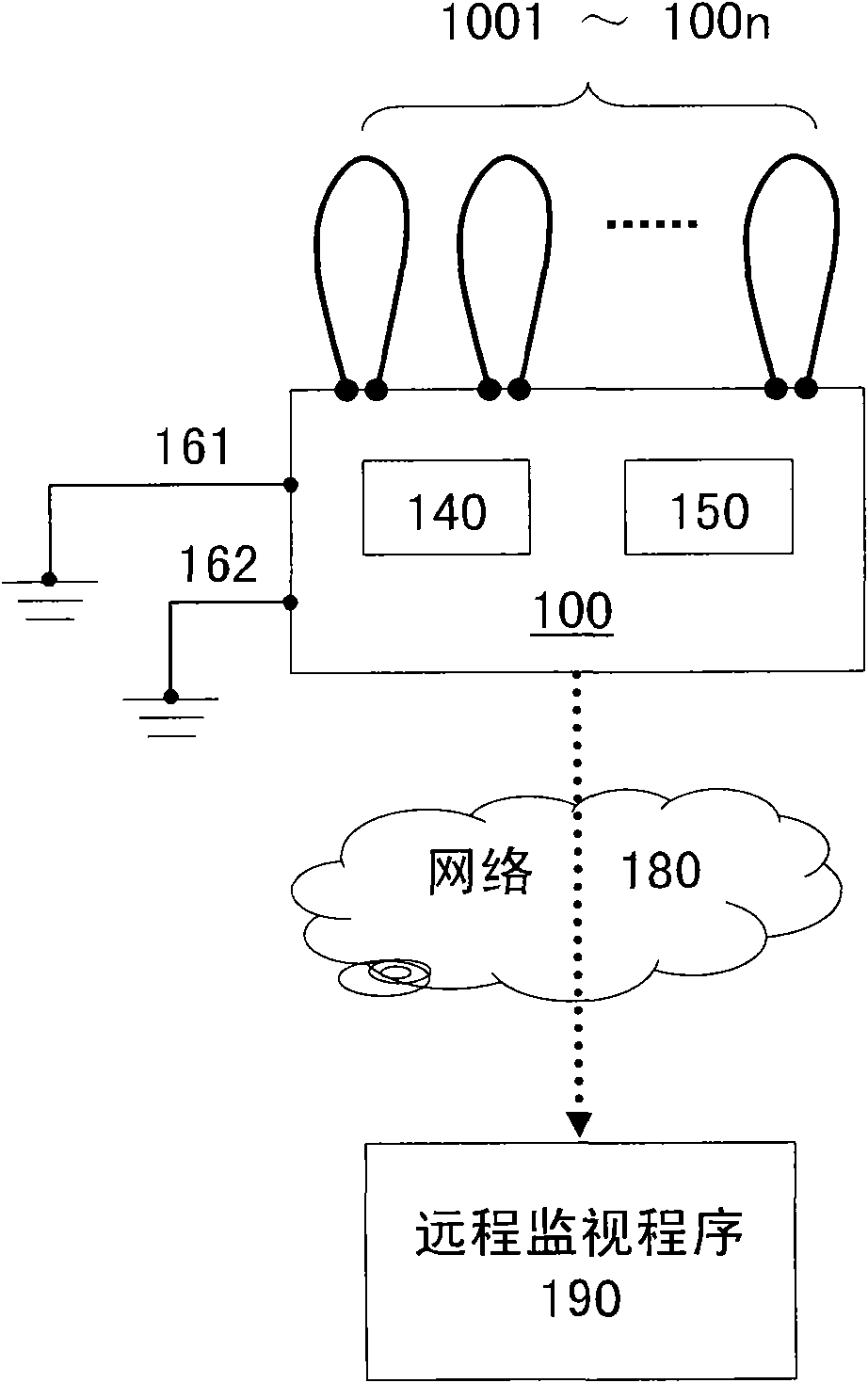

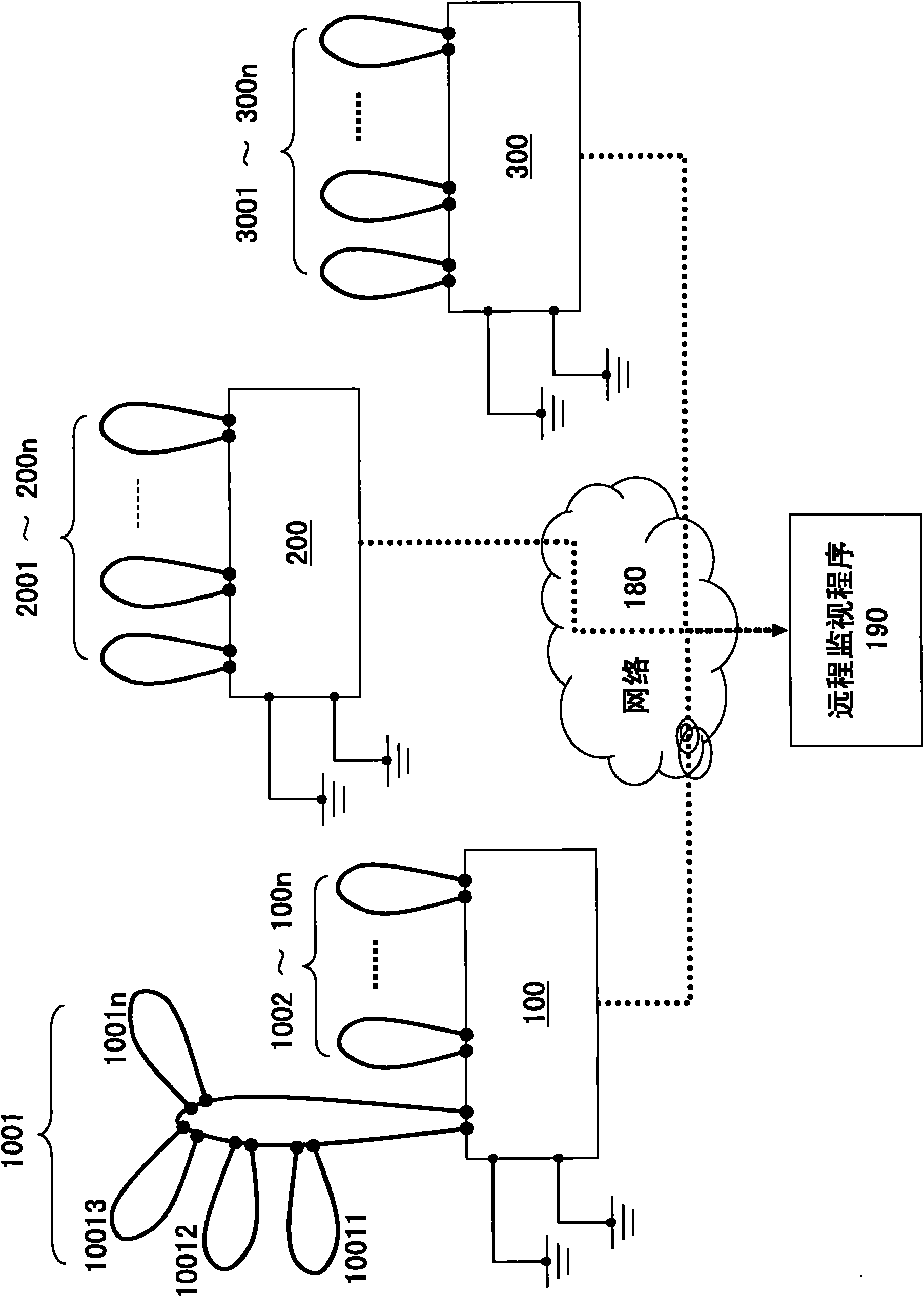

[0023] An electrostatic discharge automatic detection system proposed by the present invention can connect multiple current loops, and detect the electrostatic discharge of multiple electronic devices connected in series provided by the current loop for each current loop. Is the situation abnormal. The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings, and the technical features of the present invention will be described in detail.

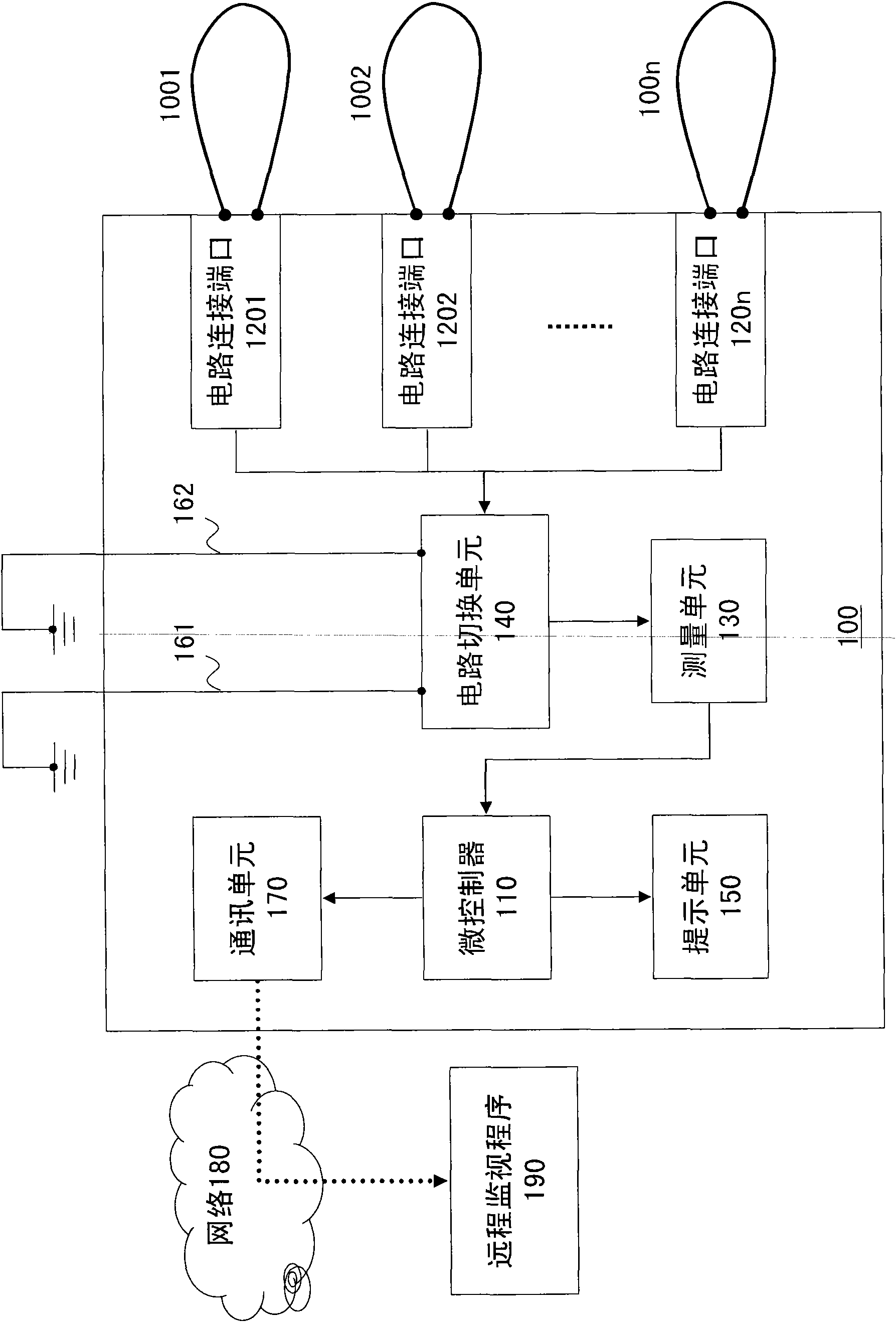

[0024] With reference figure 1 , is a schematic diagram illustrating an embodiment of an automatic electrostatic discharge (ESD) detection system. The electrostatic discharge automatic detection system 100 of the present invention is composed of a microcontroller 110, circuit connection ports 1201-120n, a measurement unit 130, a circuit switching unit 140, a prompt unit 150 and two grounding wires 161, 162 .

[0025] A plurality of circuit connection ports 1201-120n are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com