Optical semiconductor device module

An optical semiconductor element and technology for emitting light, which is applied to optical elements, semiconductor lasers, light guides, etc., can solve the problems of high manufacturing cost, insufficient sealing of optical semiconductor elements, and inability to use plastic lenses, so as to reduce manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

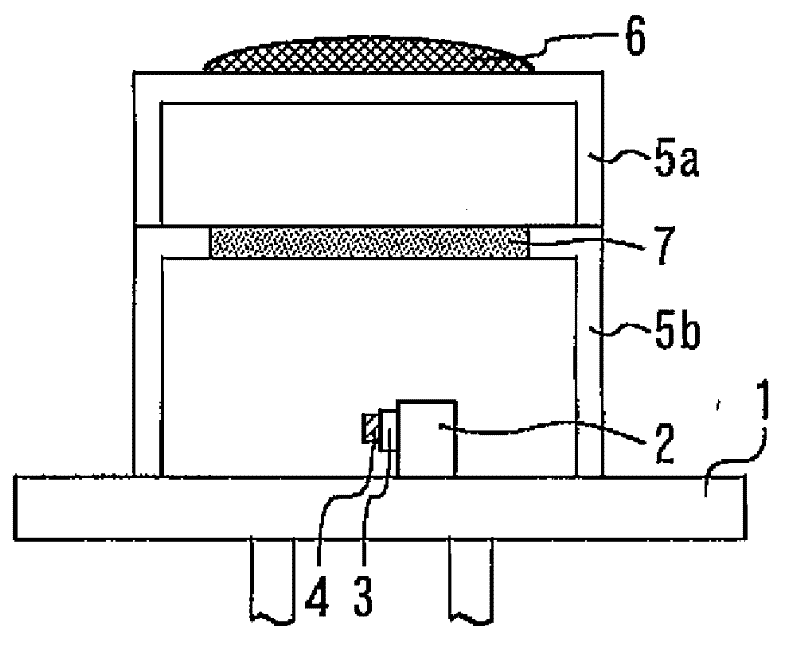

[0027] figure 1 It is a cross-sectional view showing the optical semiconductor element module of the first embodiment. A semiconductor laser 4 (optical semiconductor element) is mounted on the stem 1 via a heat sink 2 and a sub-fixture 3. A cover 5 is fixed to the stem 1 so as to cover the semiconductor laser 4. A plastic lens 6 and a glass plate 7 are mounted on the cover 5. The plastic lens 6 condenses the emitted light of the semiconductor laser 4. The glass plate 7 seals the semiconductor laser 4.

[0028] In this way, by using the glass plate 7, the semiconductor laser 4 can be sufficiently sealed. In addition, by using the plastic lens 6, the manufacturing cost can be reduced.

[0029] figure 2 It is a cross-sectional view showing a modification of the optical semiconductor element module of the first embodiment. The cover 5 has a mark 8 (guide) at the position where the plastic lens 6 is attached. With this mark 8, the plastic lens 6 can be attached to the cover 5 wit...

Embodiment approach 2

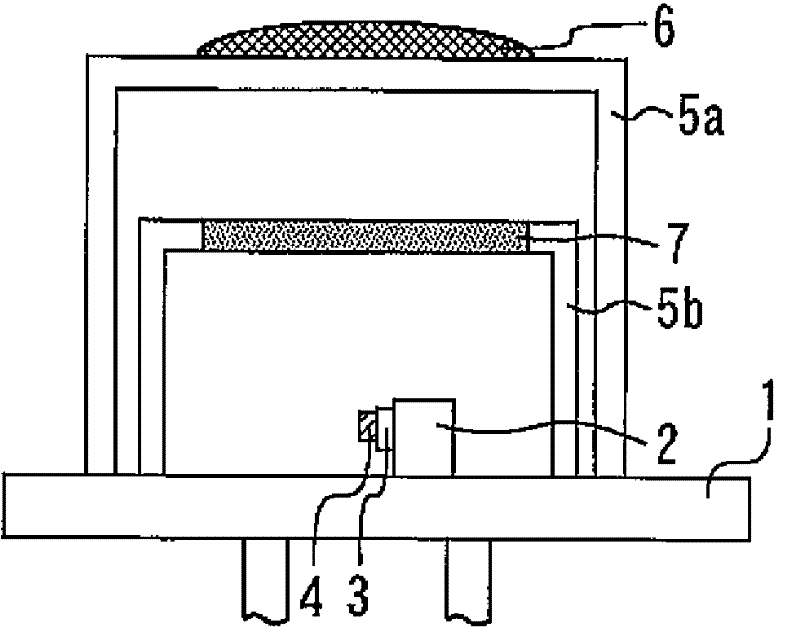

[0031] image 3 It is a cross-sectional view showing the optical semiconductor element module of the second embodiment. The cover 5 a (first cover) to which the plastic lens 6 is mounted and the cover 5 b (second cover) to which the glass plate 7 is mounted are different members. The cover 5a overlaps the cover 5b. Thereby, the cover parts 5a and 5b can be manufactured by the conventional technique.

[0032] Figure 4 It is a cross-sectional view showing Modification 1 of the optical semiconductor element module of the second embodiment. In this modification, the cover 5b is overlapped on the cover 5a, and the plastic lens 6 is closer to the semiconductor laser 4 than the glass plate 7 is. Therefore, since the plastic lens 6 is close to the light-emitting part, it is easy to condense light.

[0033] Figure 5 It is a cross-sectional view showing Modification 2 of the optical semiconductor element module of the second embodiment. In this modification, the upper cover part 5a is ...

Embodiment approach 3

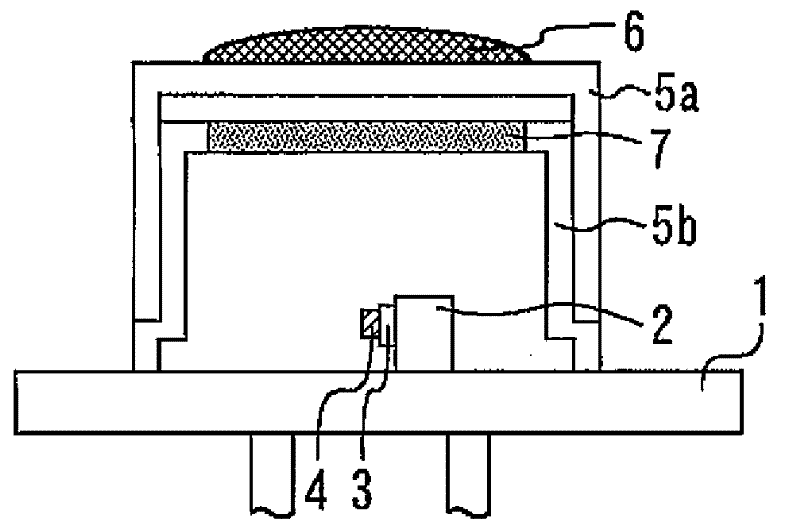

[0035] Image 6 It is a cross-sectional view showing the optical semiconductor element module of the third embodiment. The cover part 5a to which the plastic lens 6 is mounted and the cover part 5b to which the glass plate 7 is mounted are different members. The cover 5a and the cover 5b are respectively fixed to the stem 1. The cover 5a covers the cover 5b. Thereby, the cover parts 5a and 5b can be manufactured by the prior art, and the cover parts 5a and 5b can be fixed to the stem 1 by the prior art.

[0036] Figure 7 It is a cross-sectional view showing a modification of the optical semiconductor element module of the third embodiment. In this modification, the inner wall of the outer cover 5a and the outer wall of the inner cover 5b are in contact. Therefore, if the position of the inner cover part 5b is determined, the position of the outer cover part 5a is automatically determined, so there is no need for positioning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com