Holding table

A workbench and workpiece technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as unusable, device quality degradation, device damage, etc., to reduce charge, suppress static electricity, and suppress electrostatic damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Next, an embodiment of the present invention will be described.

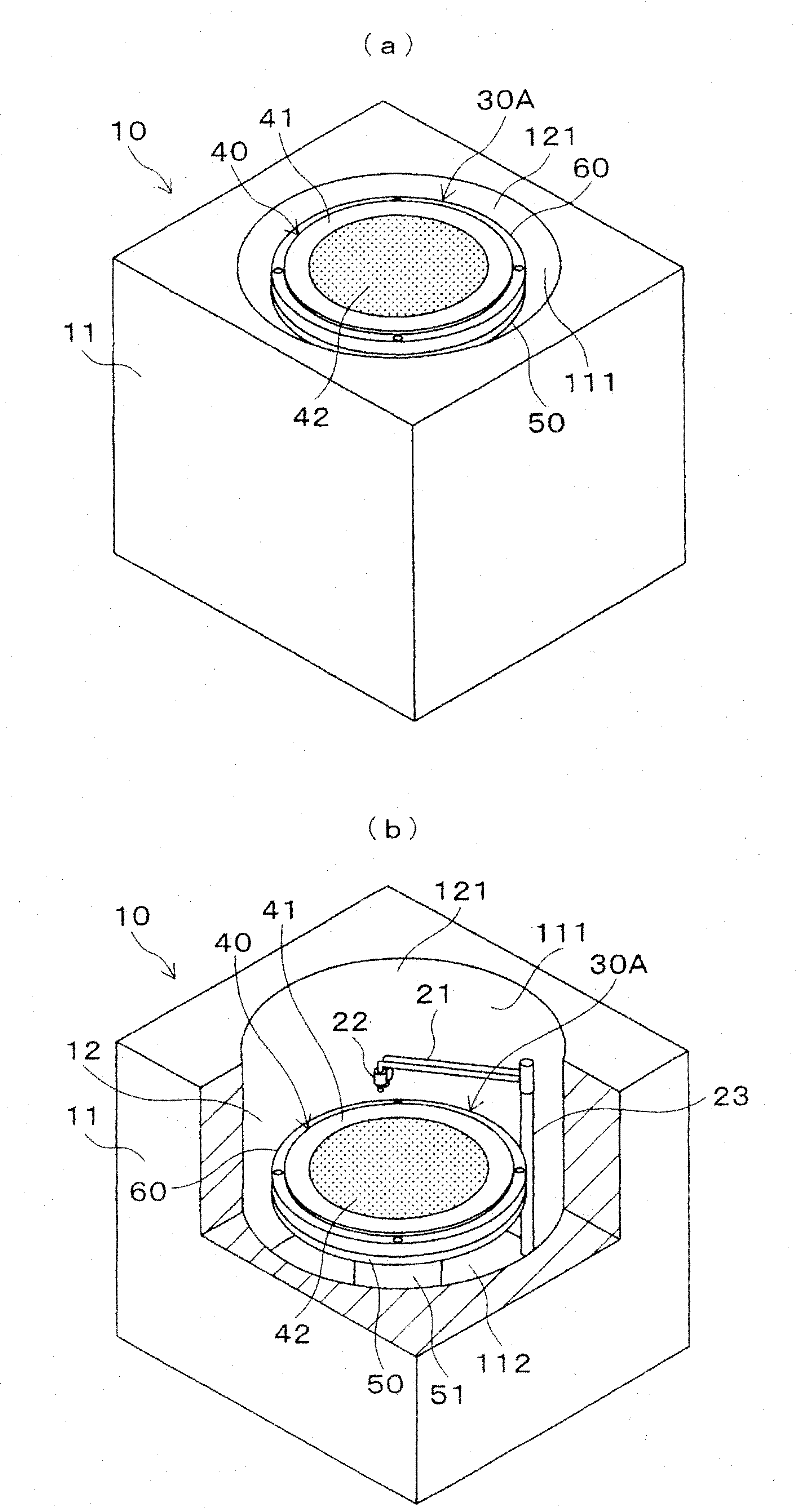

[0028] [1] Cleaning device

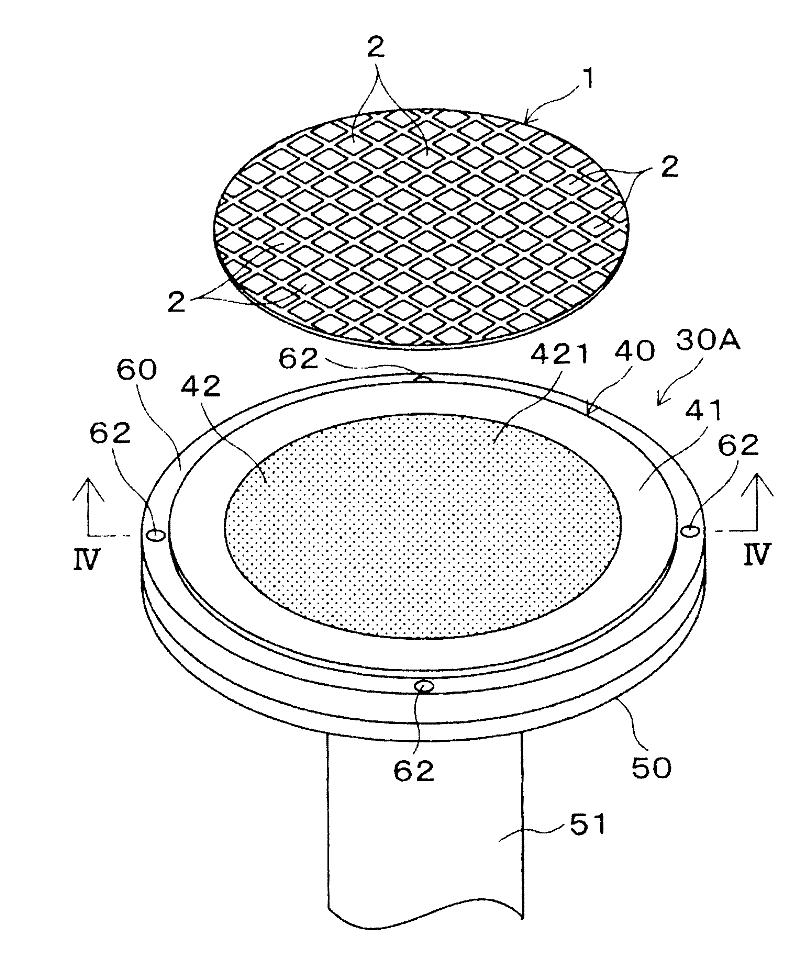

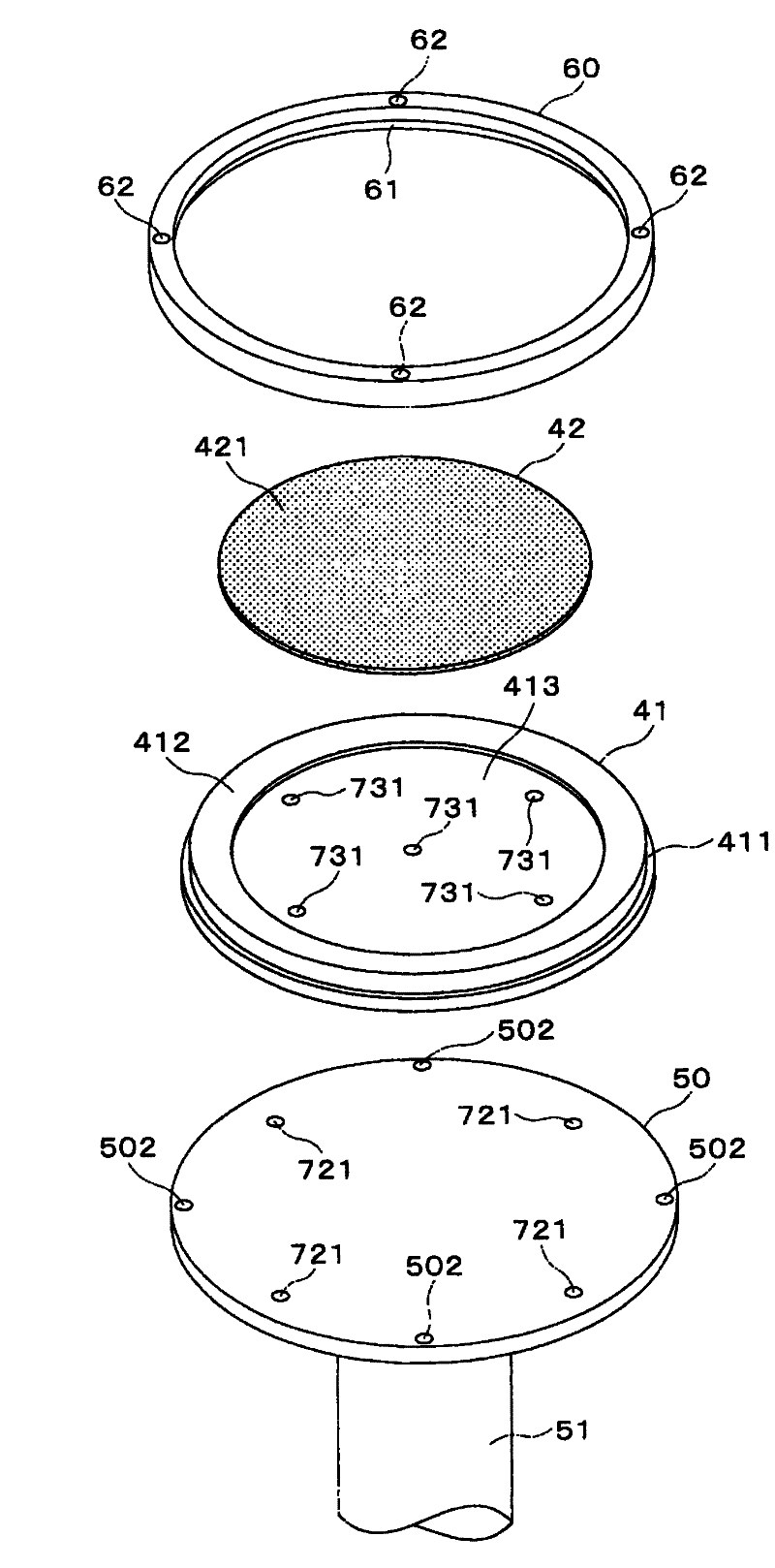

[0029] figure 1 The cleaning device 10 to which the holding table 30A of one embodiment is applied is shown. This cleaning device 10 is preferable as a device for cleaning a thin-plate-shaped workpiece subjected to predetermined processing with a processing device not shown. figure 2 The number 1 of the indicates the artifact here. The workpiece 1 is a disc-shaped semiconductor wafer on the surface of which a large number of rectangular-shaped devices 2 having electronic circuits are formed.

[0030] Examples of processing devices for the workpiece 1 include cutting (scribing) (including cutting with a cutting tool or cutting by laser irradiation), drilling with a laser, grinding, lapping, expanding ( エキスビンド: expand) A processing device such as split processing. The cleaning device 10 of the present embodiment is attached to the processing device described above, or is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com