Press felt and method for producing the same

A technology for a press felt and a production method, applied in textiles and papermaking, papermaking, papermaking, etc., can solve the problems of high cost and troublesome film production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

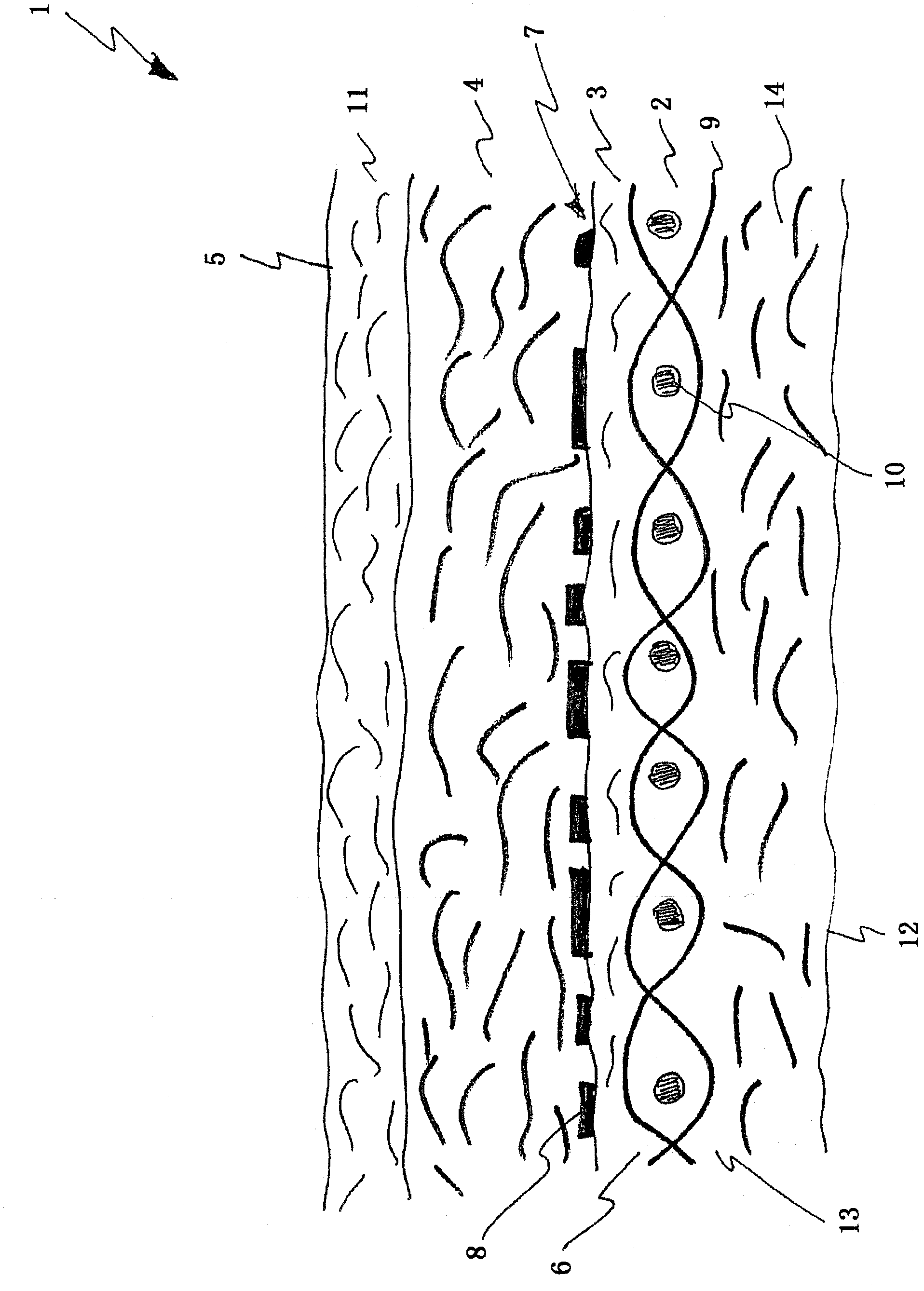

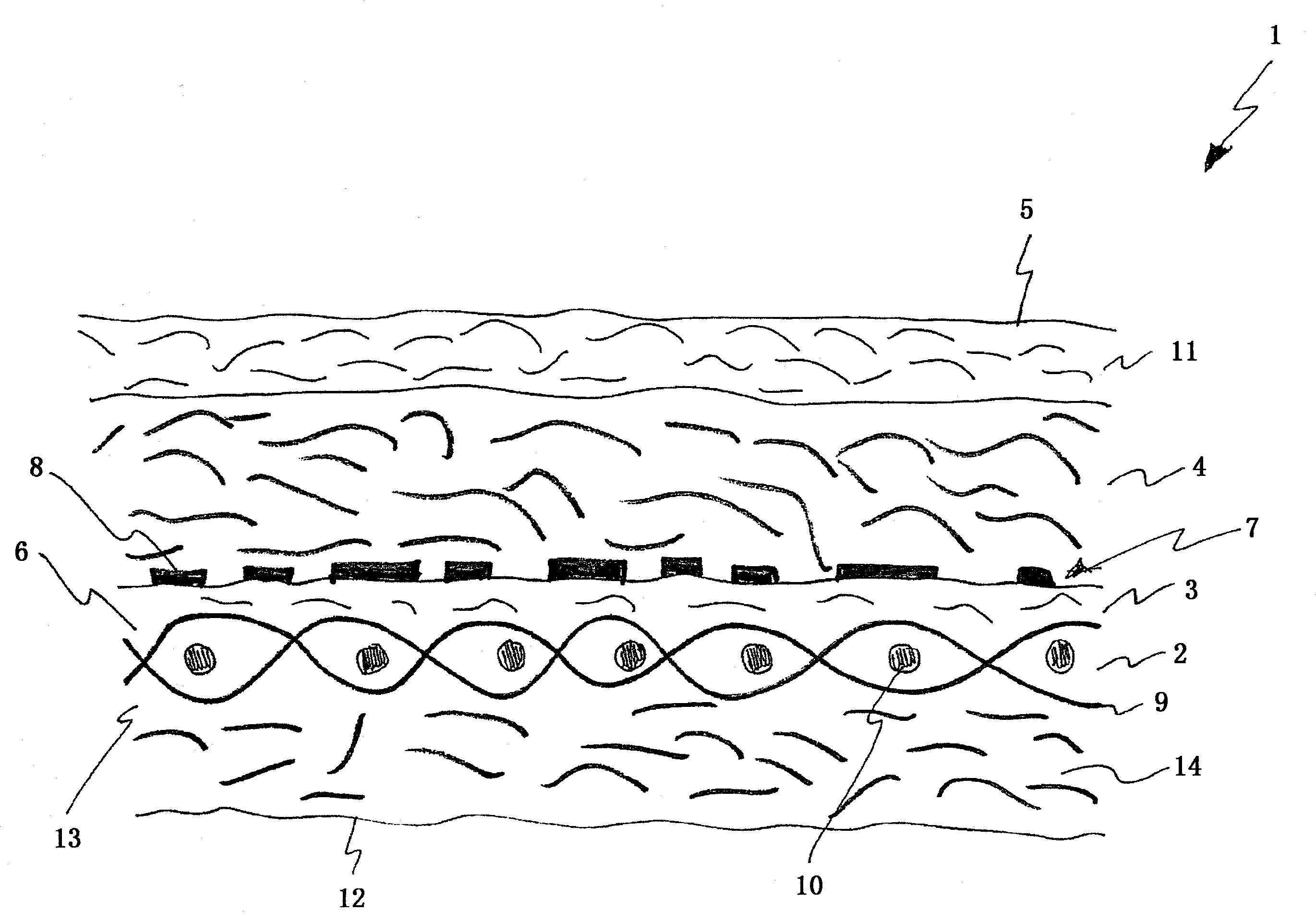

[0042] The press felt 1 has a load-bearing basic structure consisting of a fabric 2 as well as a first 3 and a second nonwoven fiber layer 4 . The first and second nonwoven fiber layers 3, 4 are superimposed on the side 6 of the basic structure 2 directed towards the paper side 5 of the press felt. The fabric 2 is composed of interwoven longitudinal threads 9 and transverse threads 10 . According to the invention, the pattern 7 of polymer pattern elements 8 printed on the first nonwoven fiber layer 3 is arranged between two superimposed nonwoven fiber layers 3 , 4 and partially covers it.

[0043] A further nonwoven fiber layer 11 providing the paper side 5 is arranged above the second nonwoven fiber layer 4 . As shown, the first nonwoven fibrous layer 3 is composed of finer fibers than the second nonwoven fibrous layer 4 .

[0044] When producing the press felt 1 firstly the first nonwoven fiber layer 3 is arranged on the basic structure 2 and combined with the basic struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com