New glue dissolving technology of soft capsules

A soft capsule and new technology technology, applied in the field of soft capsule sol technology in the pharmaceutical industry, can solve problems such as glue quality and achieve the effect of accelerating the melting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

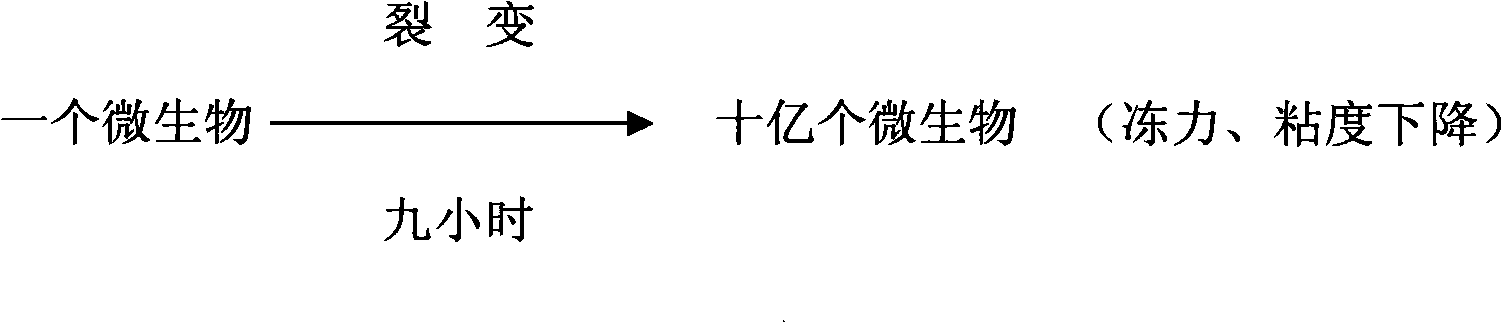

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Open the feeding port, put in the weighed purified water, glycerin, and sorbitol according to the sol formula, close the feeding port, start stirring, and raise the temperature of the mixed solution to 62°C, and keep the temperature of the interlayer water at 60°C during the entire sol process ℃~80℃.

[0033] (2) Open the feeding port, slowly add gelatin into the sol tank while stirring, and control the speed of glue feeding to avoid gelatin agglomeration and affect the effect of gelatinization. After the glue feeding is completed, close the feeding port and lock it tightly, and turn on the vacuum pump to vacuumize the negative pressure sol.

[0034] (3) During the sol process, observe the conditions in the tank and the changes in temperature and pressure at all times to prevent the glue from being sucked away. After the pressure reaches -0.06Mpa, turn off the vacuum pump and maintain this negative pressure for 45 minutes. Break the vacuum to observe that the gela...

Embodiment 2

[0038] (1) Open the feeding port, put in the weighed purified water, glycerin, and sorbitol according to the sol formula, close the feeding port, start stirring, and raise the temperature of the mixed solution to 65°C, and keep the temperature of the interlayer water at 60°C during the entire sol process ℃~80℃.

[0039] (2) Open the feeding port, slowly add gelatin into the sol tank while stirring, and control the speed of glue feeding to avoid gelatin agglomeration and affect the effect of gelatinization. After the glue feeding is completed, close the feeding port and lock it tightly, and turn on the vacuum pump to vacuumize the negative pressure sol.

[0040] (3) During the sol process, observe the conditions in the tank and the changes in temperature and pressure at all times to prevent the glue from being sucked away. After the pressure reaches -0.06Mpa, turn off the vacuum pump and maintain the negative pressure for 40 minutes. Break the vacuum to observe that the gelat...

Embodiment 3

[0044] (1) Open the feeding port, put in the weighed purified water, glycerin, and sorbitol according to the sol formula, close the feeding port, start stirring, and raise the temperature of the mixed solution to 68°C, and keep the temperature of the interlayer water at 60°C during the entire sol process ℃~80℃.

[0045] (2) Open the feeding port, slowly add gelatin into the sol tank while stirring, and control the speed of glue feeding to avoid gelatin agglomeration and affect the effect of gelatinization. After the glue feeding is completed, close the feeding port and lock it tightly, and turn on the vacuum pump to vacuumize the negative pressure sol.

[0046] (3) During the sol process, observe the conditions in the tank and the changes in temperature and pressure at all times to prevent the glue from being sucked away. After the pressure reaches -0.06Mpa, turn off the vacuum pump and maintain the negative pressure for 50 minutes. Break the vacuum to observe that the gelat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com