Self-tightening and position-adjustable tailstock for grinder

An automatic technology for tailstock adjustment, which is applied in the direction of grinding workpiece supports, etc., can solve the problems of inability to adjust the jacking force, consume manpower, and cannot adjust the jacking force, and achieve the adjustable function of the cylinder jacking force and facilitate the axis The effect of telescopic adjustment and quick clamping range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

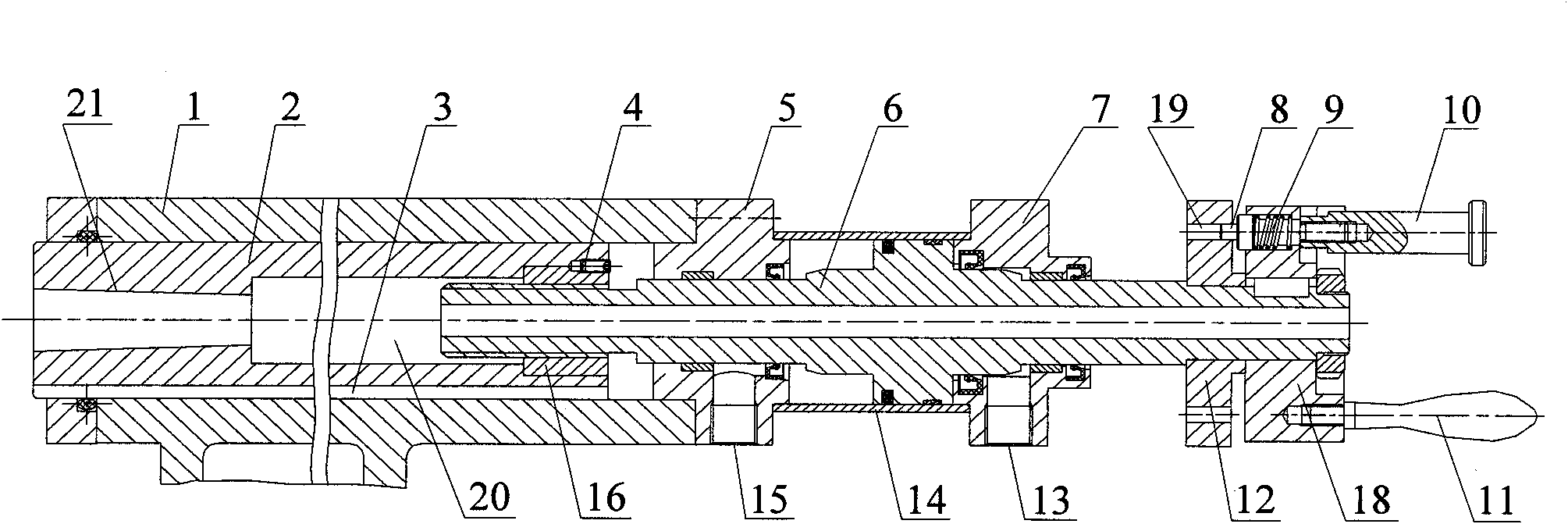

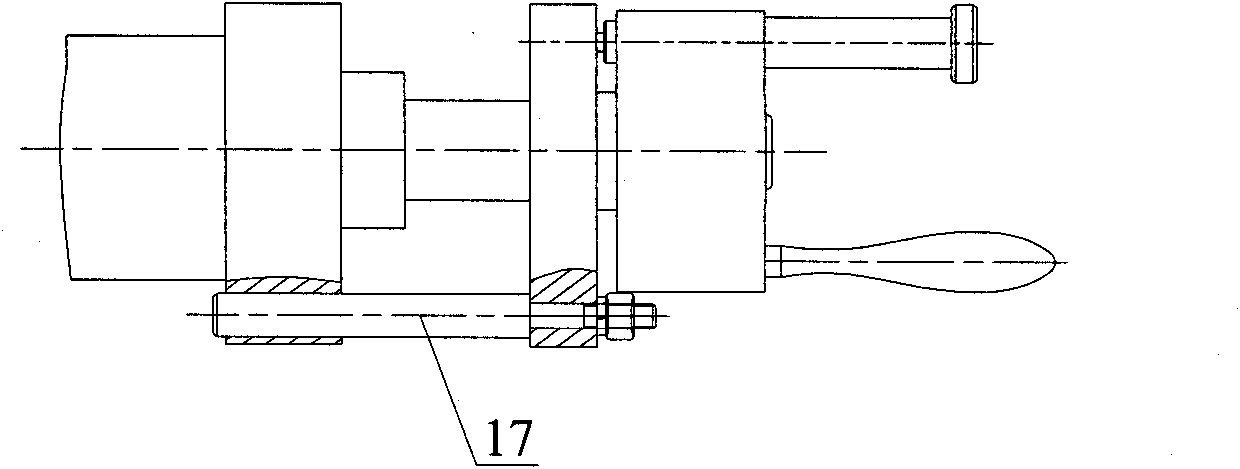

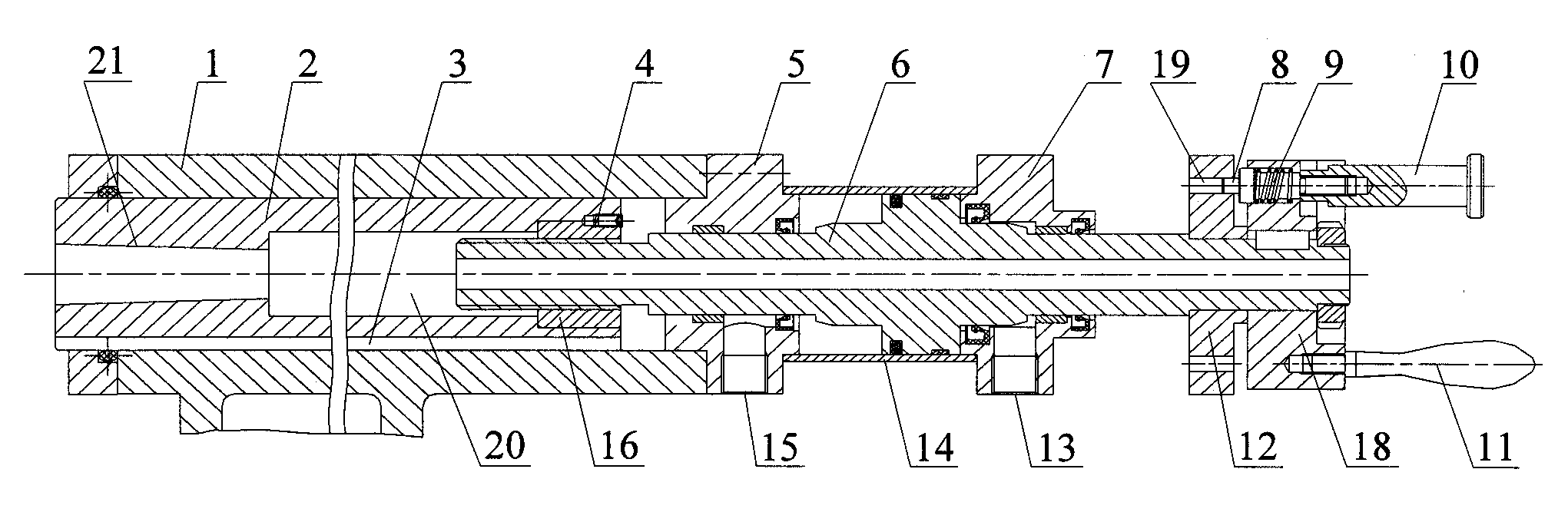

[0016] Such as Figure 1-2 As shown, the automatic tightening and position-adjustable tailstock for a grinding machine according to the embodiment of the present invention includes a sleeve 2 with a Morse taper hole 21 installed inside the tailstock box 1, and the surface of the sleeve 2 is set There is a longitudinal guide groove, and the guide groove is connected with the guide key 3 installed in the tailstock box body 1, so that the guide groove can slide along the guide key 3; the non-working end of the tailstock box body 1 Fixedly connected with a cylinder 14, the two ends of the cylinder 14 are respectively the front end cover 5 and the rear end cover 7, and the piston rod 6 of the cylinder 14 passes through the center of the front end cover 5 and the rear end cover 7; one end of the piston rod 6 is processed The external thread is inserted into the inner hole 20 of the sleeve 2, and a nut 16 matching the external thread of the piston rod 6 is fixed at the end of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com