Man-machine separation combined production equipment for firework black powder

A production equipment and black powder technology, applied in explosive processing equipment, offensive equipment, explosives, etc., can solve the problems of black powder crushing function, black powder screening, black powder quality decline, etc., to achieve man-machine Isolation and unmanned production, the realization of mechanized automatic production, and the effect of improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

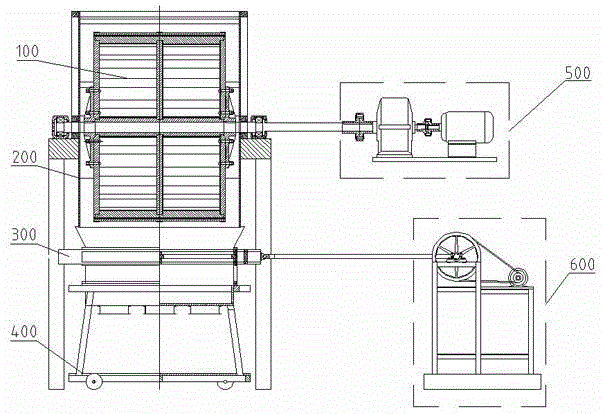

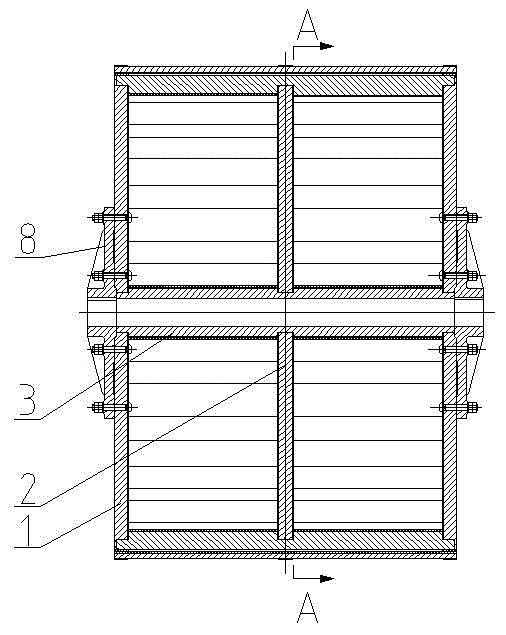

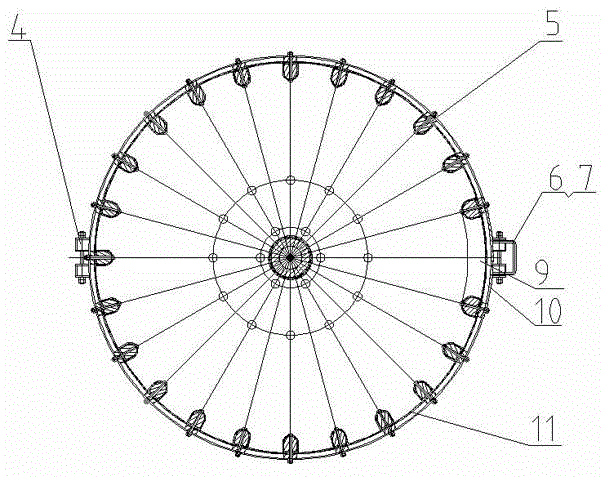

[0021] Combine figure 1 The man-machine isolation combined production equipment for fireworks and black medicine of the present invention is composed of a wooden drum 100, a hood 200, a motorized screen 300, a receiving trolley 400, a driving device 500, and a motorized screen driver 600. The main shaft 25 of the driving device 500 passes through the wood The drum 100 positions and supports the wooden drum 100, and the hood 200 covers the outside of the wooden drum 100 to support and protect the wooden drum 100. Below the hood 200 is a motorized screen 300, which is hung on the machine through a connecting cloth 19 On the cover 200 and below the motorized screen 300 is the receiving trolley 400, the connecting cloth 19 in the motorized screen 300 is placed in the trolley hopper box 23 of the receiving trolley 400, the wooden drum 100, the hood 200, the motorized screen 300 and the receiving The material trolley 400 is placed in the same workshop, and the driving device 500 and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com