Device for separating cotton-polyester blended fabrics and repolymerizing polyester

A polyester-cotton blended spinning and separation device technology, applied in recycling technology, plastic recycling and other directions, can solve the problems of difficult recycling of polyester-cotton blended fabrics, and the recycling and reuse of polyester-cotton blended fabrics have not been well resolved, and achieve continuous separation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

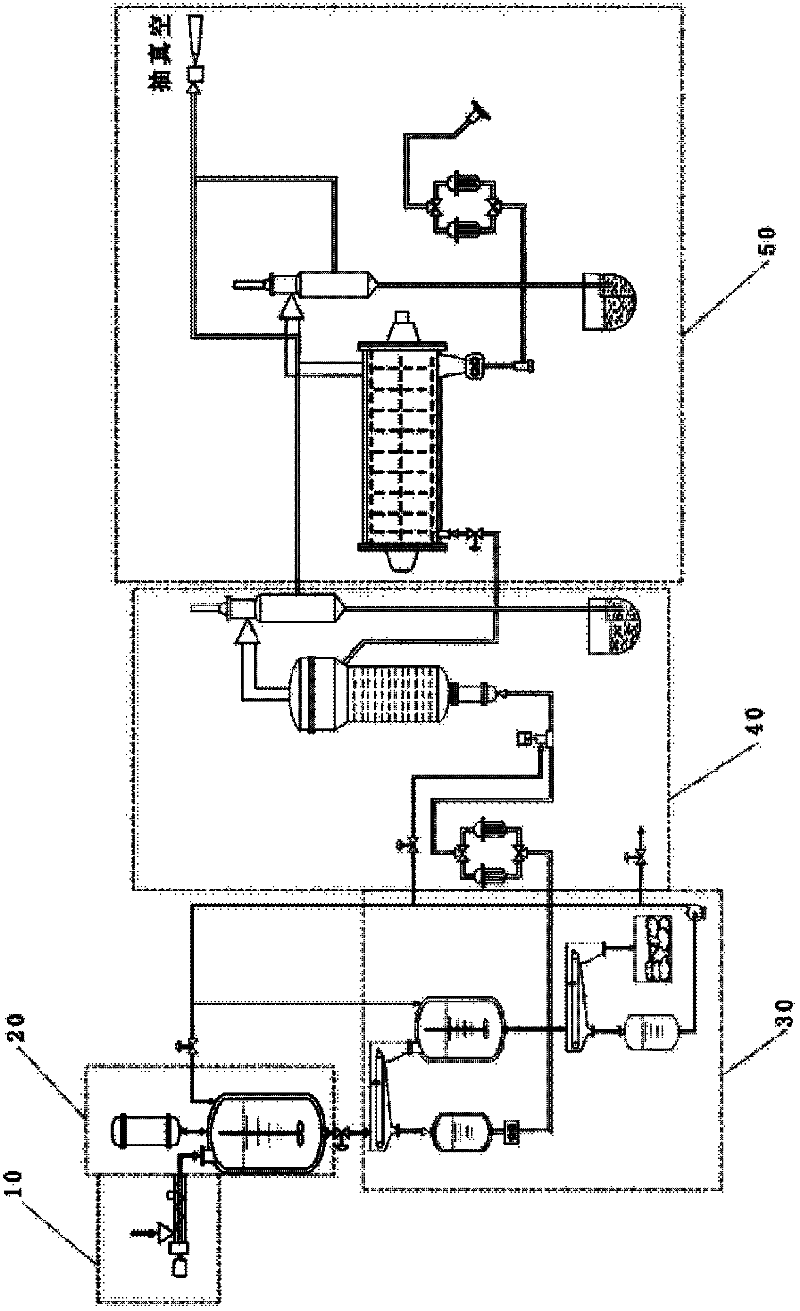

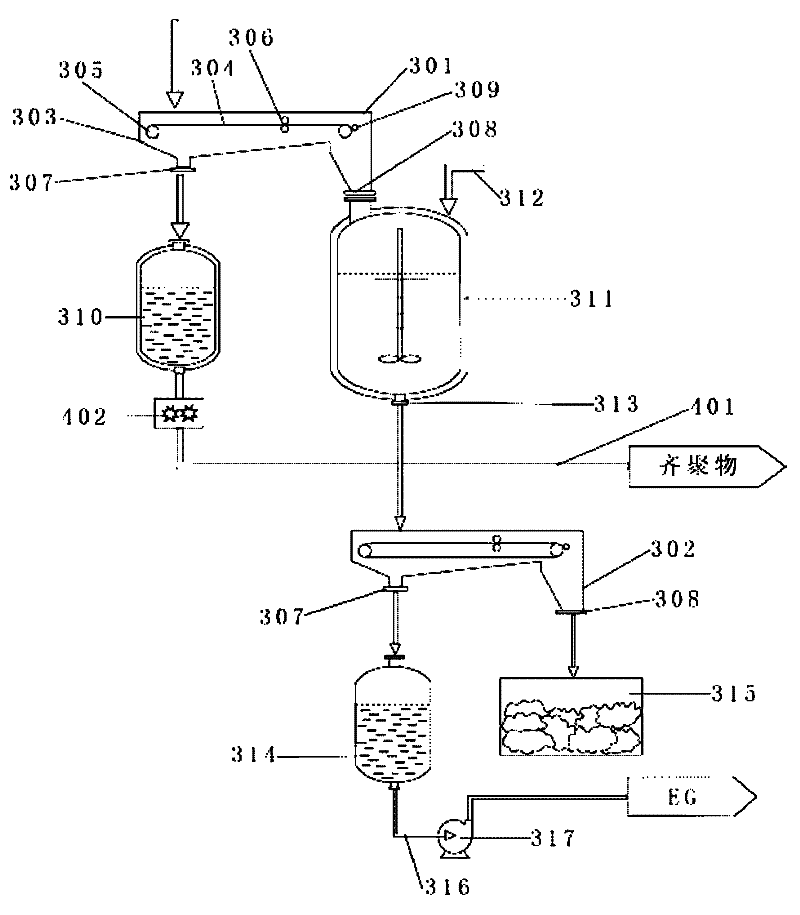

[0019] Such as figure 1 As shown, the device of the present invention includes a feeding mechanism 10 , an alcoholysis reaction mechanism 20 , a continuous separation mechanism 30 , a precondensation mechanism 40 and a final polycondensation mechanism 50 .

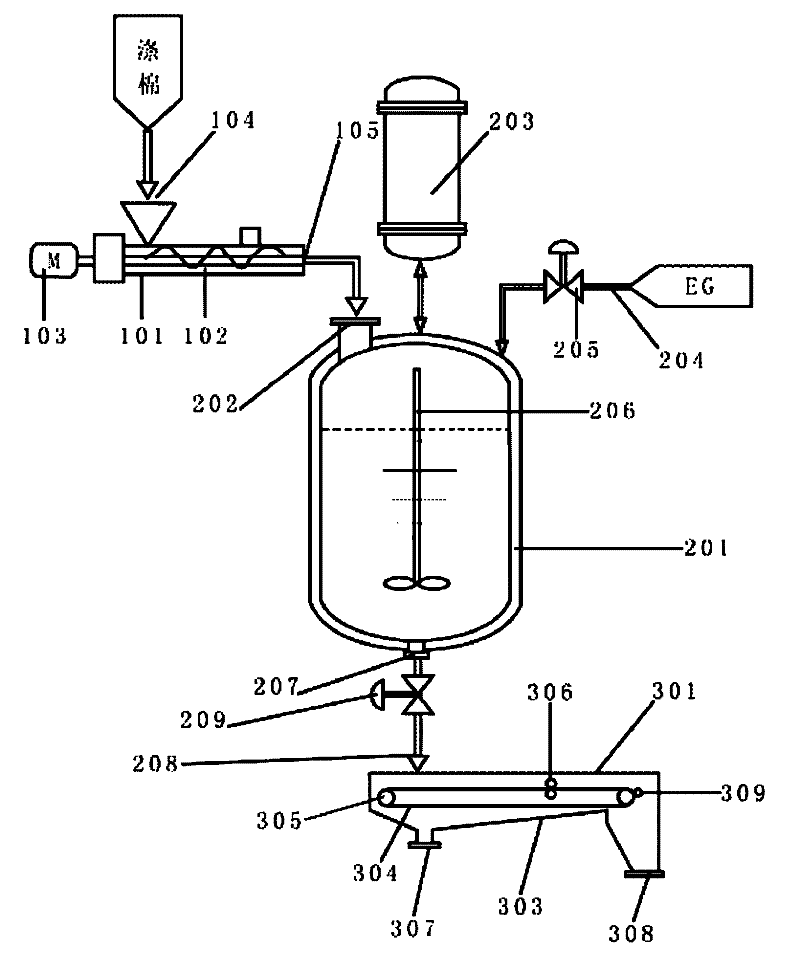

[0020] Such as figure 1 , figure 2 As shown, the feeding mechanism 10 includes a cavity barrel 101. A drive screw 102 is arranged in the cavity barrel 101. The power input end of the drive screw rod 102 is connected to the output shaft of the motor 103. One end of the cavity barrel 101 is provided with a material inlet 104, and the other end A discharge port 105 is provided.

[0021] Such as figure 1 , figure 2 As shown, the alcoholysis reaction mechanism 20 includes an alcoholysis reactor 201 with automatic heating function, the top of the alcoholysis reactor 201 is provided with a feed po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com