Novel adjustable liquid spraying ring

An adjustable, liquid ring technology, used in furnace types, furnaces, heat treatment equipment, etc., can solve problems such as passive work and achieve good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

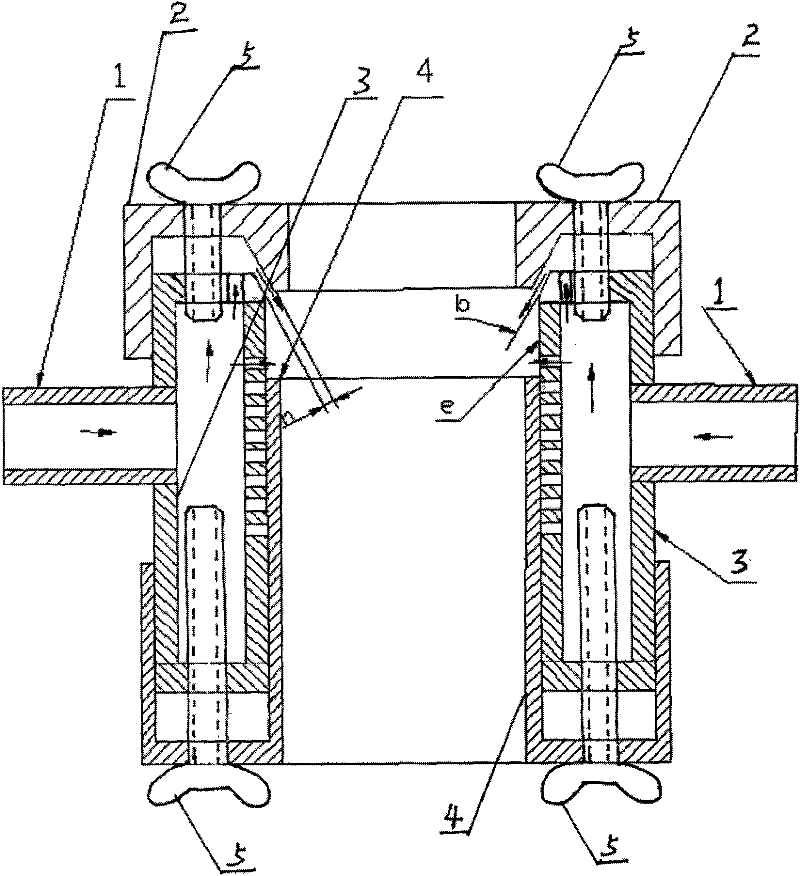

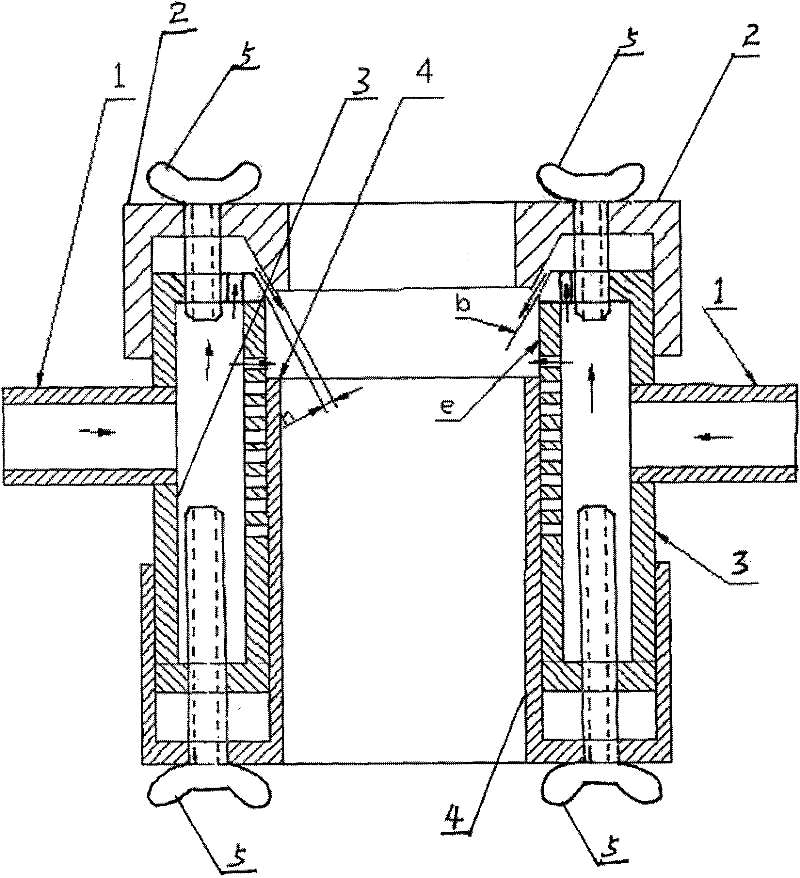

[0009] Between the inclined cone surface of the water curtain adjustment cap (2) and the inclined cone surface on the liquid spray ring (3), a liquid spray channel b that can be closed and opened is respectively arranged, and the liquid spray ring (3) is connected with the water There is an adjustable butterfly screw (5) on the curtain adjustment cap (2), unscrew the butterfly screw (5) to open the channel b on the inclined cone surface of the water curtain adjustment cap (2), and tighten the water curtain adjustment The channel b of the oblique cone surface of the cap (2) is closed; a plurality of small liquid spray holes are respectively opened on the inner test e surface corresponding to the opposite liquid spray ring (3), and the liquid spray ring (3) and the water mist adjustment sleeve (4) is provided with an elastically adjustable butterfly screw (5), so, tightening or loosening the butterfly screw (5) and the advance and retreat of the water mist adjustment sleeve (4) c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com