Insulation layer thermal-shrinkage furnace for capacitor

A heat shrinkable furnace and insulating layer technology, which is applied in capacitors, capacitor manufacturing, circuits, etc., can solve the problems of poor heat shrinkage performance, inability to use, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

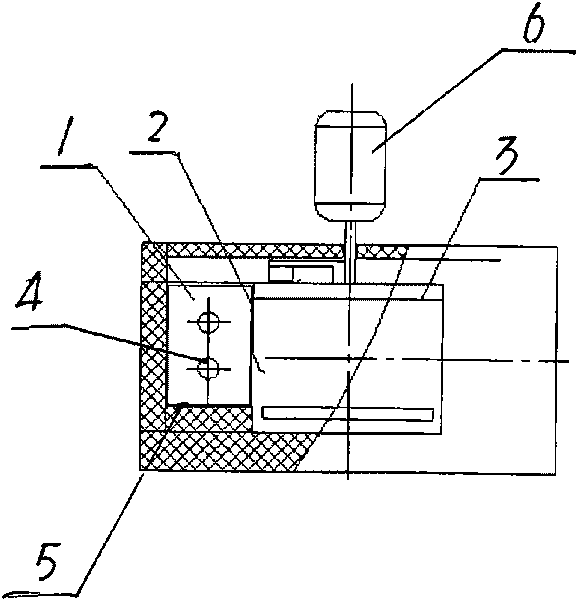

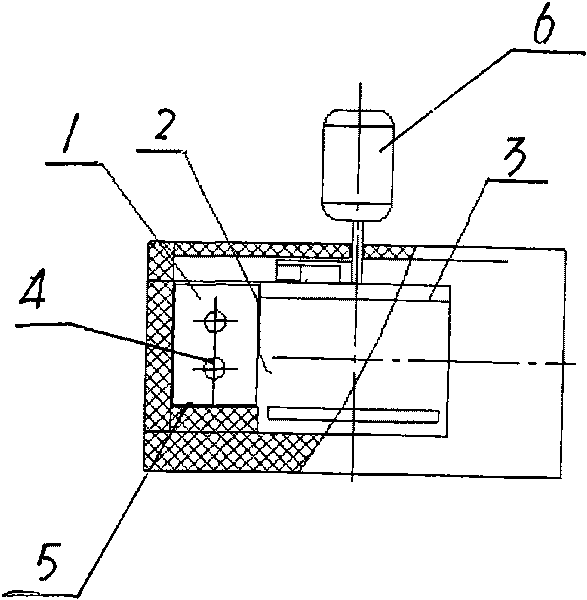

[0009] exist figure 1 In the process, the capacitor covered with the insulating protective layer enters the heat-shrinkable furnace under the conveying belt 5, and the electric heater 1 heats the insulating layer of the capacitor through the temperature control system. Plate 3 is hollow, and its entrance to air inlet at air outlet 4 places is from large to small in size, and air outlet baffle plate 2 is communicated with blower port, and outlet size is from high temperature section to low temperature section from large to small. The temperature of the furnace is heated by the electric heater 1, and the temperature of the furnace is regulated by the temperature controller with the temperature adjustment function. The motor drives the drum fan 6 to make the temperature in the furnace uniform. The gas flow direction of the gas plays a key role. When the capacitors covered with the insulating protective layer pass through, in sequence, at a temperature of 120°C-240°C and a flow ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com