Energy-saving spring type hydraulic power machine

A spring type, power machine technology, applied in the direction of brake actuators, fluid pressure actuation devices, fluid pressure actuation system components, etc., can solve safety accidents, safety hazards and other problems, to reduce consumption, smooth hydraulic flow, save energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

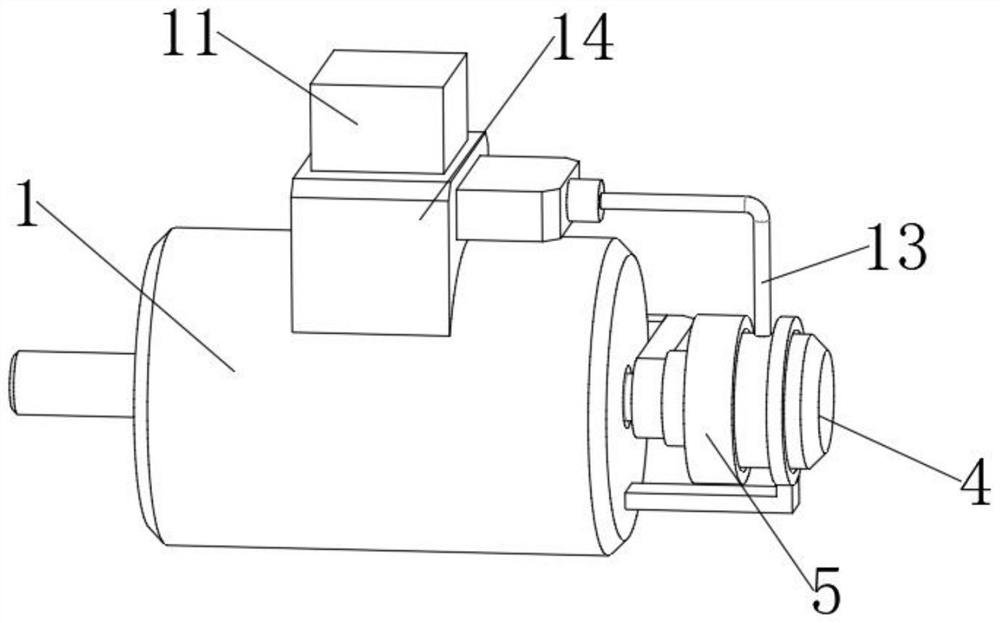

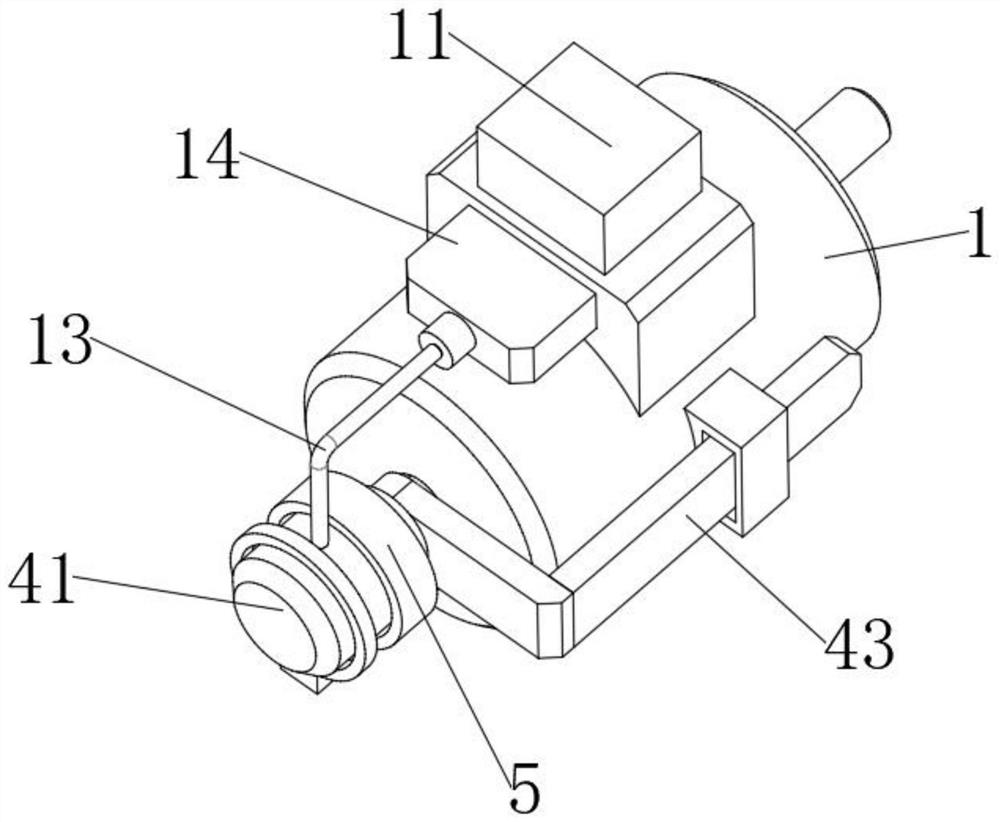

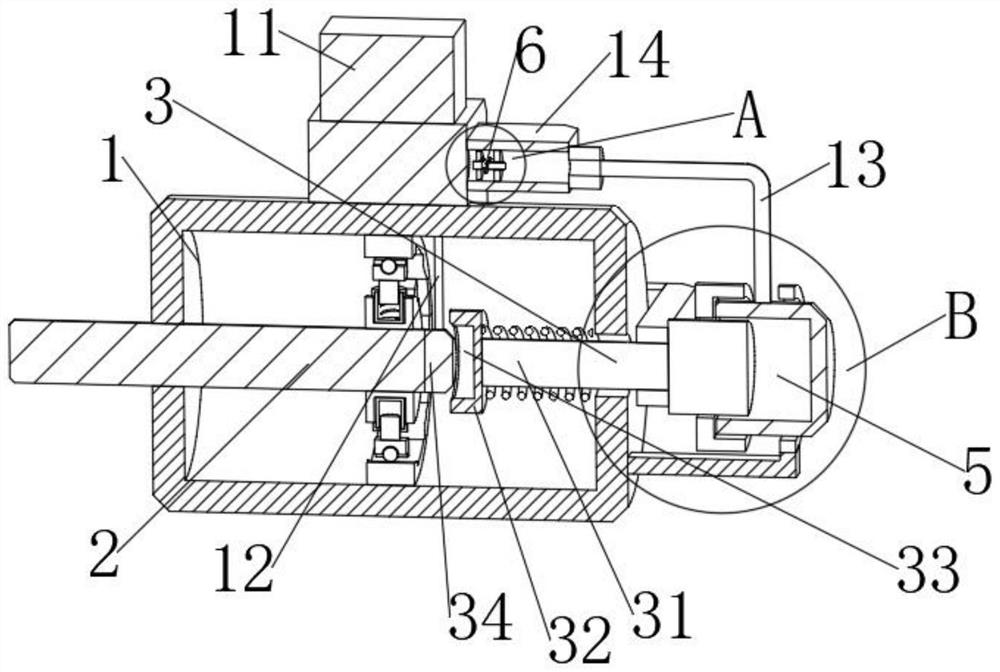

[0035] see Figure 1-3 , comprising a motor housing 1, the motor housing 1 is provided with a hydraulic shaft 2 for rotation, and the motor housing 1 is also provided with a braking mechanism 3, the braking mechanism 3 is used to stop the hydraulic shaft 2 from rotating;

[0036] The brake mechanism 3 includes a brake lever 31 slidably arranged on the motor housing 1. The brake lever 31 is provided with a groove 33, and the hydraulic shaft 2 is provided with a block 34 that is compatible with the groove 33. And the block 34 is slidably disposed in the groove 33 .

[0037] In this embodiment: in order to quickly stop the hydraulic shaft 2, a braking mechanism 3 is provided on the motor housing 1, and the braking mechanism 3 can accelerate the stopping of the hydraulic shaft 2, thereby reducing the consumption of hydraulic oil.

[0038] Stall: The brake lever 31 can be slid towards the direction close to the hydraulic shaft 2 through an external device, so that the block 34 on ...

Embodiment 2

[0041] This embodiment is an improvement made on the basis of Embodiment 1, please refer to Figure 1-3 , The brake lever 31 is also provided with a return spring 35 , and the brake lever 31 is elastically connected to the motor housing 1 through the return spring 35 .

[0042] In this embodiment: in order to reset the brake lever 31, a return spring 35 is provided on the brake lever 31. When the brake lever 31 loses its external limit, the return spring 35 will produce a reverse force on the brake lever 31. Push force, so that the brake lever 31 slides towards the direction close to the motor housing 1, and then the brake lever 31 is far away from the hydraulic shaft 2, so that the hydraulic shaft 2 can rotate again.

Embodiment 3

[0044] This embodiment is an improvement made on the basis of Embodiment 2, please refer to Figure 1-3 , The motor housing 1 is provided with a protrusion 32 that is compatible with the brake lever 31 , and the brake lever 31 is slidably disposed in the protrusion 32 .

[0045] In this embodiment: in order to support the brake lever 31, prevent the brake lever 31 from falling off when sliding on the motor housing 1, thus causing the brake lever 31 to be stuck between the hydraulic shaft 2, resulting in hydraulic pressure The rotating shaft 2 cannot resume rotation, and the motor housing 1 is also provided with a bump 32, and the brake lever 31 is slidably arranged in the bump 32, and the sliding of the brake lever 31 can be supported and limited by the bump 32 , thereby preventing the brake lever 31 from falling off from the motor housing 1 during the sliding process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com