Multiple double-cavity conjoined capsule type high flow leakproof pump

A large flow, pump body technology, applied in the field of large flow non-leakage pumps, can solve the problems of short life, pollute the environment, easy to leak, etc., and achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

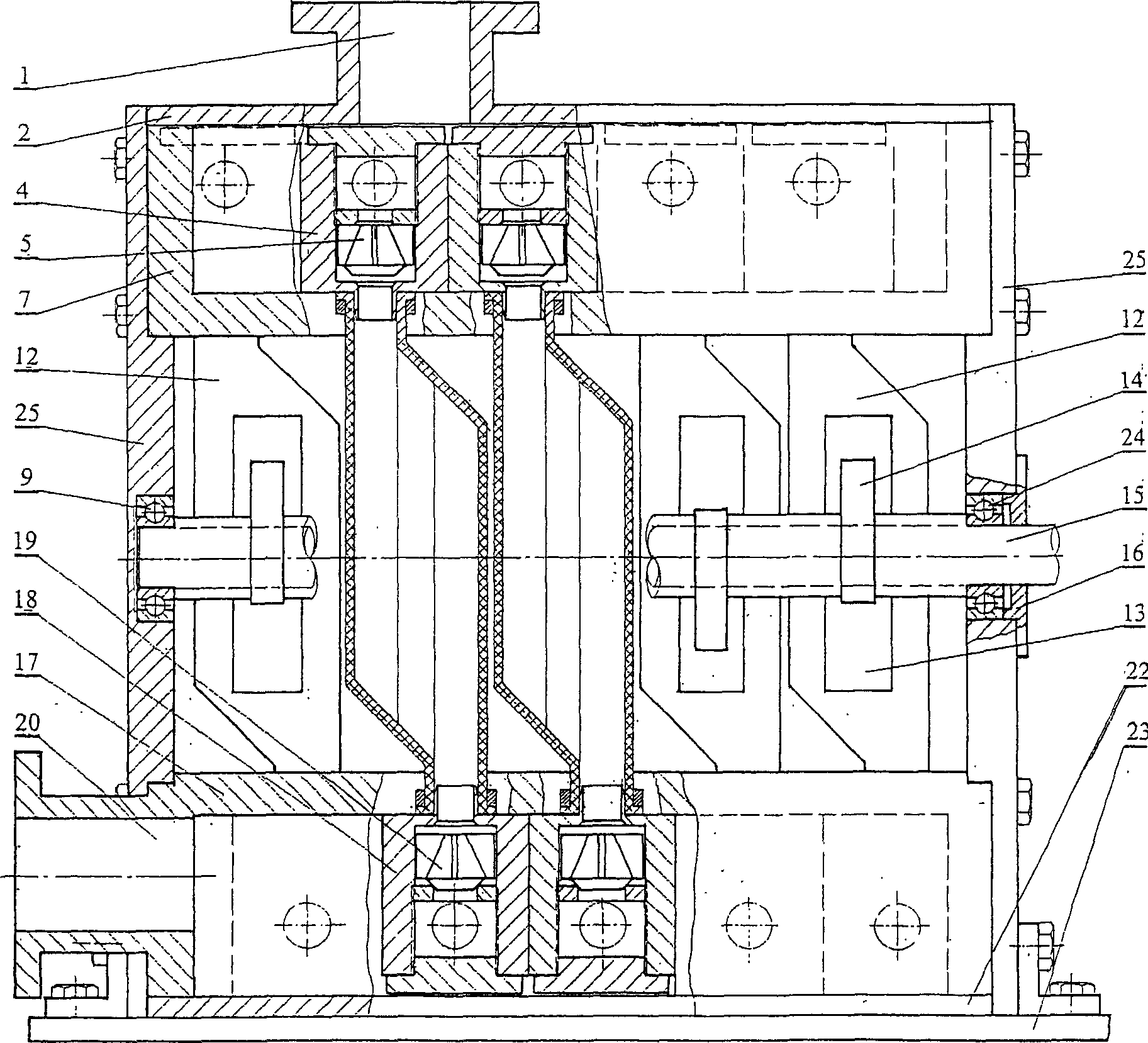

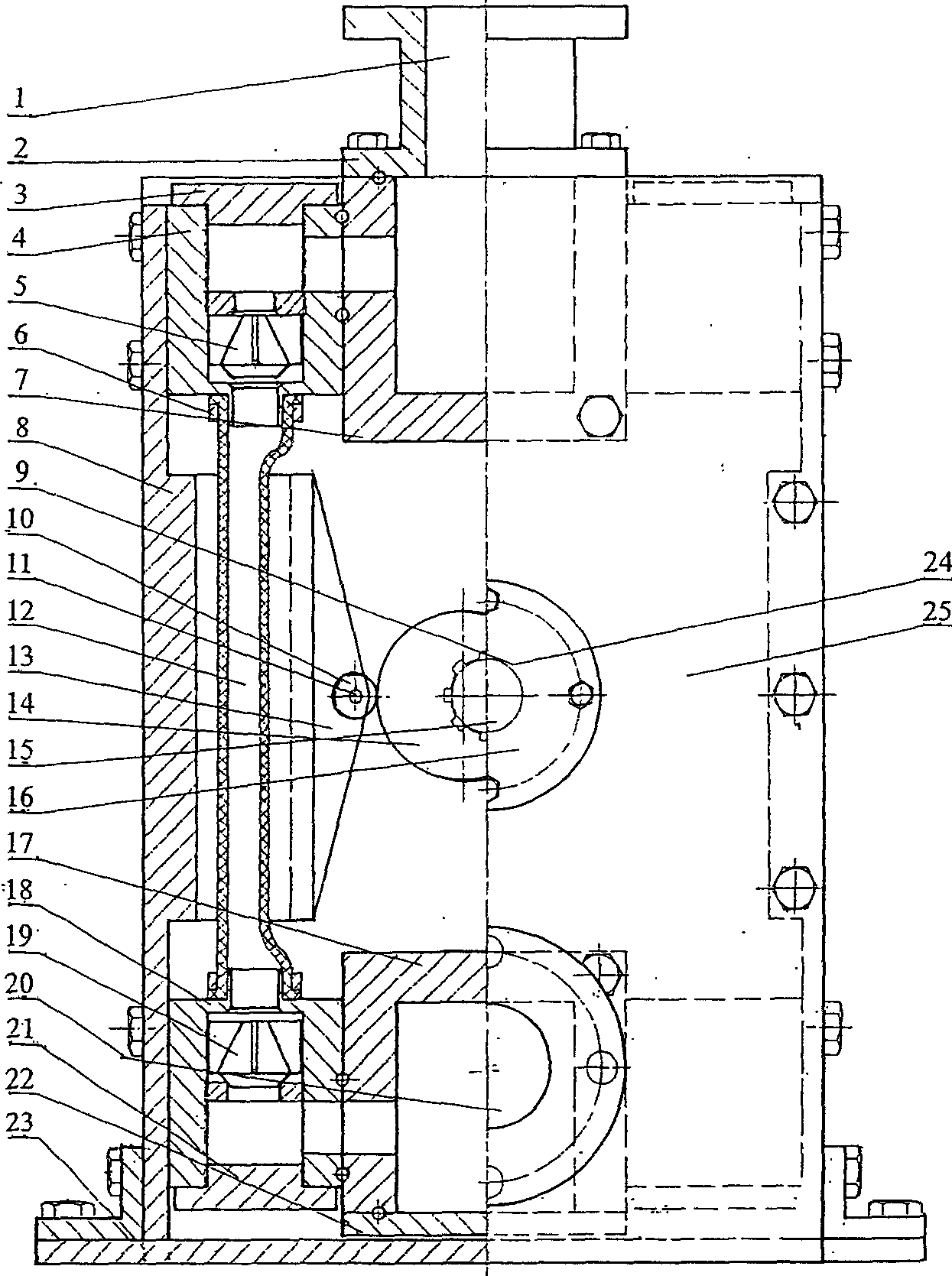

[0013] see figure 1 , the pump body is composed of a high-pressure water storage tank 7, a low-pressure water storage tank 17, two main boards 8, and two side plates 25. The main shaft 15 is arranged on the side plates 25 through bearings 9 and 24, and five cams 14 are installed On the main shaft 15, the main shaft 15 is connected with a 3.2KW motor (not shown) and rotates around the center of the bearings 9 and 24 under the drive of the motor, thereby driving each cam 14 to rotate, so that each cam 14 drives the corresponding pressure bracket respectively 13 makes a linear reciprocating motion, so that each pressure support 13 repeatedly squeezes ten double-chamber conjoined bladders 12 connected in parallel in two rows on the opposite side. , the high-pressure valve 5 and the low-pressure valve 19 are alternately opened and sealed. When the high-pressure valve 5 is opened, the low-pressure valve 19 is sealed to prevent the fluid from entering the capsule, forcing the fluid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com