Ejector sleeve device mechanism

A pipe groove and material trough technology is applied in the field of integrated circuit testing and sorting machines, which can solve the problems of unstable limit function of the push pipe device, partial replacement of the push pipe groove, and left and right shaking of the material pipe, so as to save the vertical direction. Space, manpower saving, and the effect of reducing manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

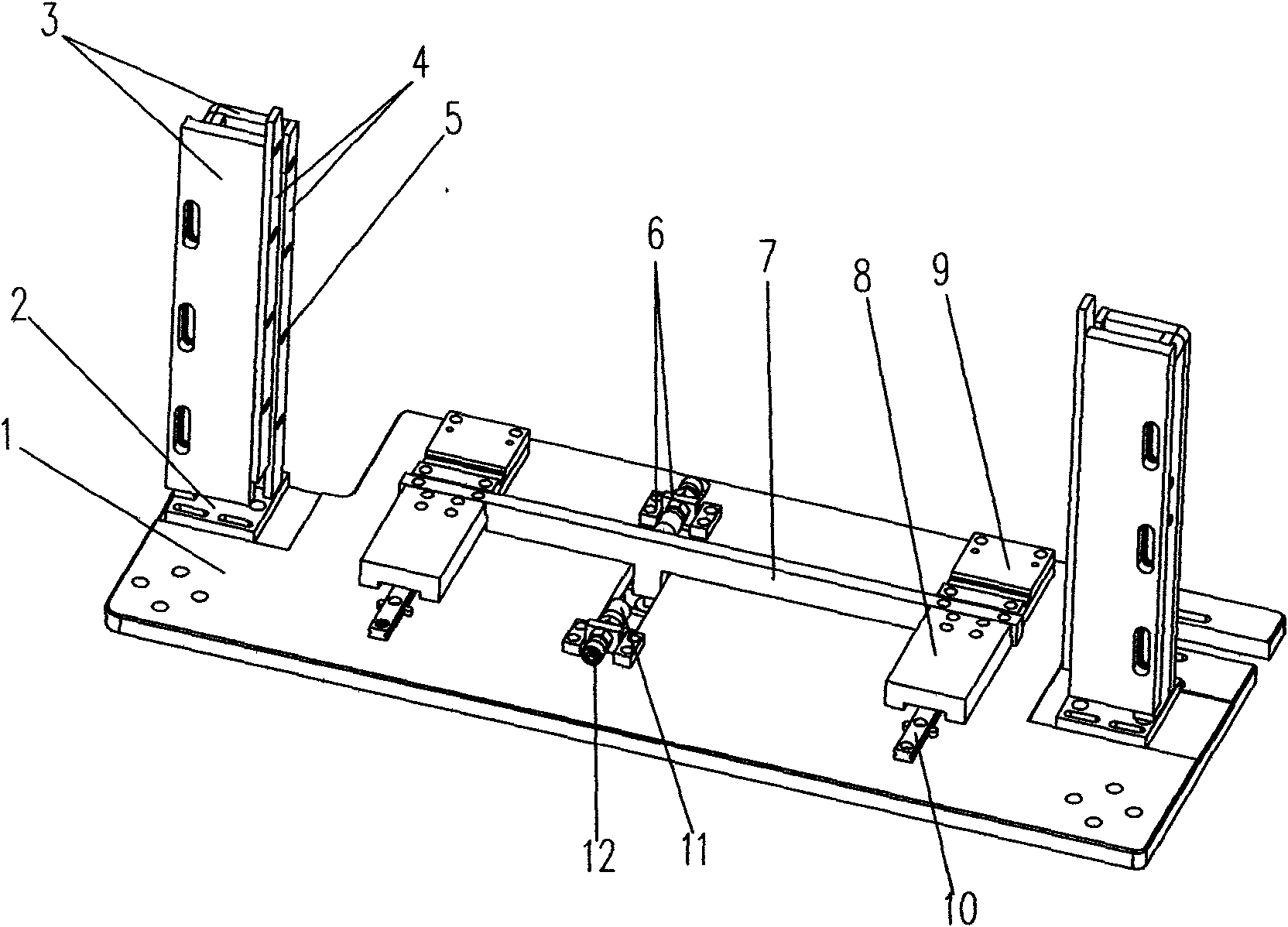

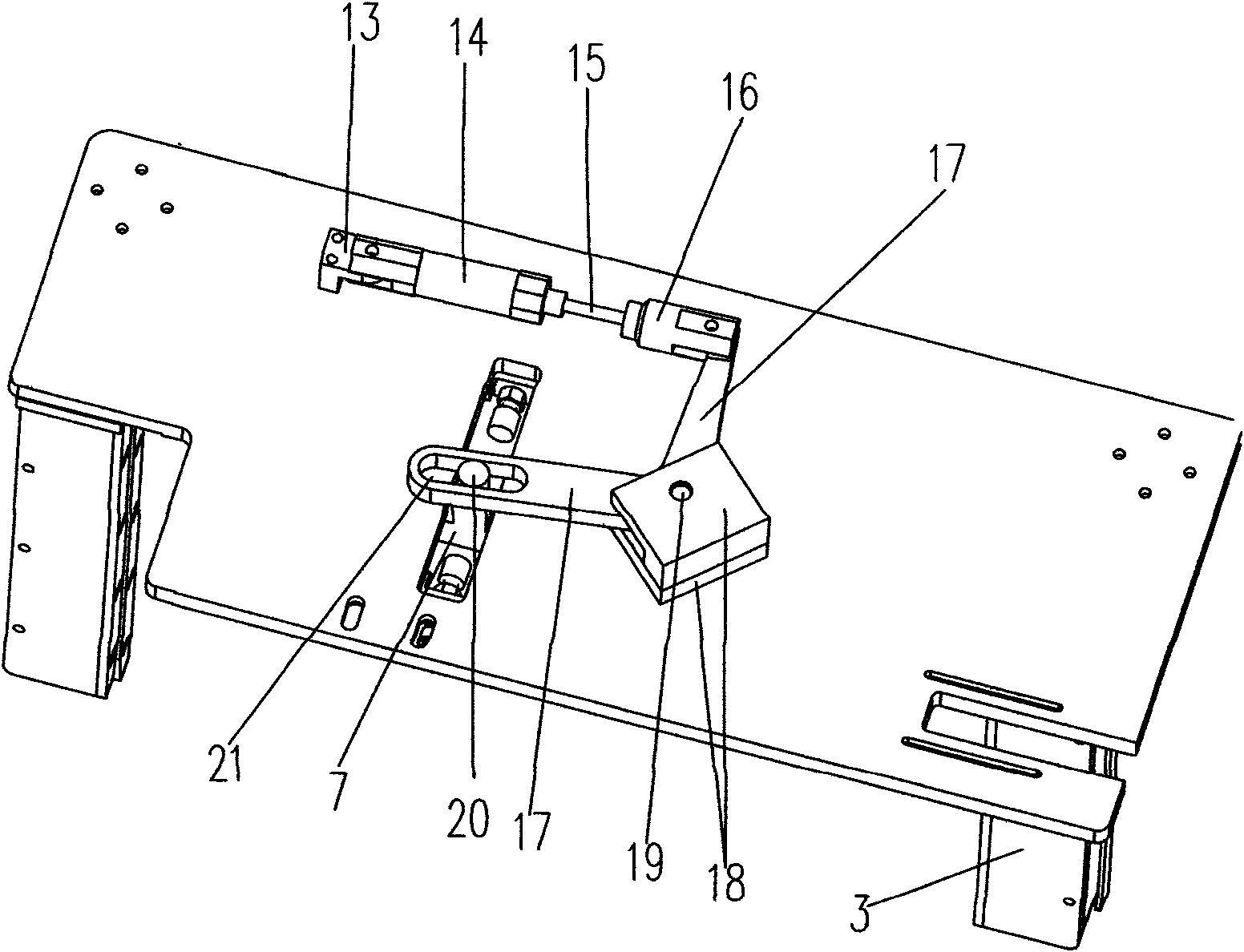

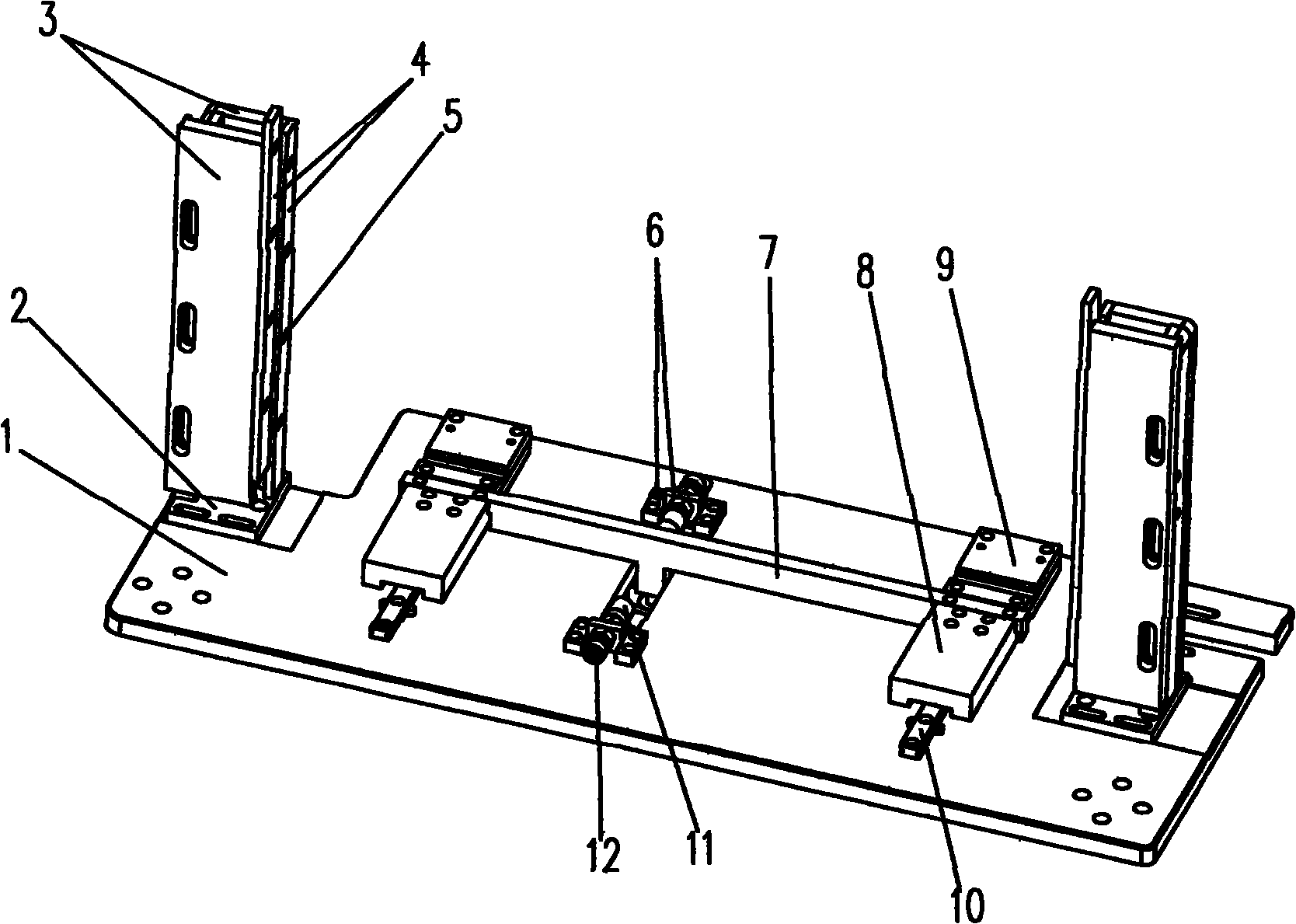

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings: Figure 1-2 Shown: a pipe pushing device mechanism, which includes: a bottom plate 1;

[0023] A feeding mechanism and a tube pushing mechanism arranged on one side of the bottom plate 1; the two feeding slots 3 of the feeding mechanism are respectively arranged at both ends of the bottom plate 1; two sliding rails 10 of the tube pushing mechanism It is fixed in parallel between the two feeding troughs (3) on the bottom plate 1; the sliding rail 10 is fixed with two push tube groove fixing plates 8; the two push tube groove fixing plates (8 ) The connecting rod 7 of the pipe pushing device is embedded between;

[0024] A driving device arranged on the other side of the bottom plate 1; one end of the cylinder block 14 of the driving device is connected to an L-shaped single elbow joint 13; the other end of the cylinder block 14 is connected to a cylinder piston rod 15; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com