Multi-cyclone separation filter equipment

A technology of cyclone separation and filtration device, which is applied in the direction of combined device, separation method, and dispersed particle separation, etc., which can solve the problems of easy blockage of the filter device and poor dust isolation effect, and achieve the effect of quick and convenient cleaning and increased suction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

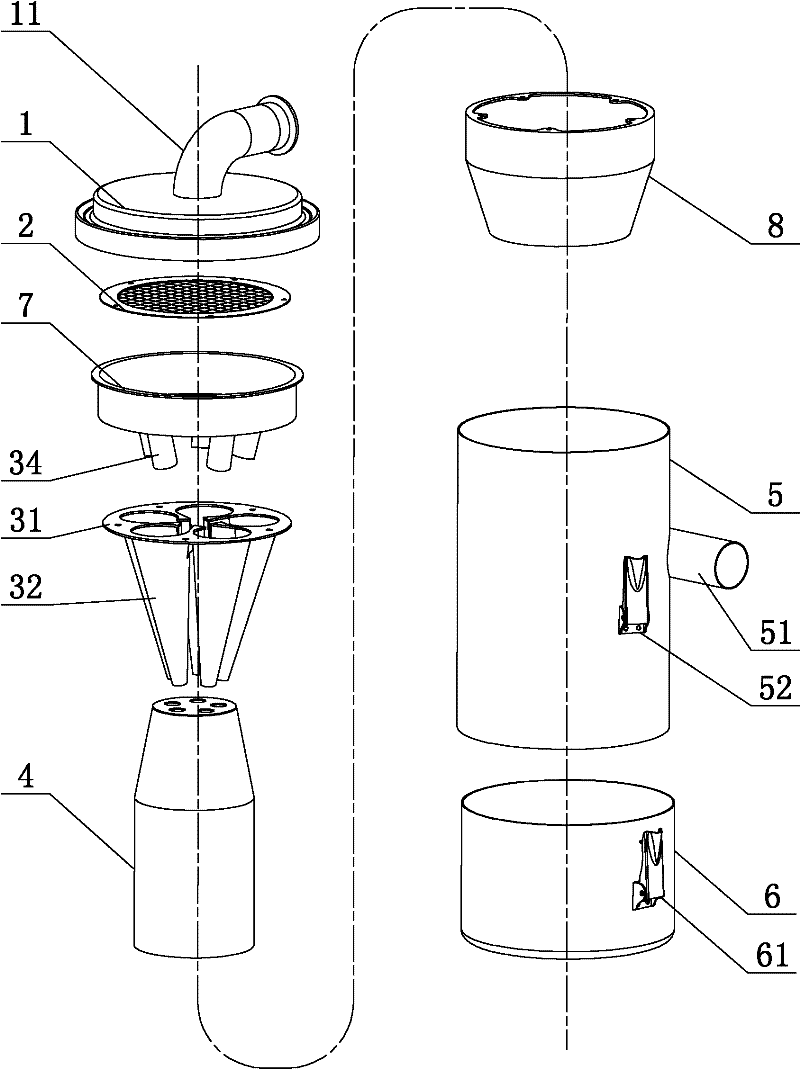

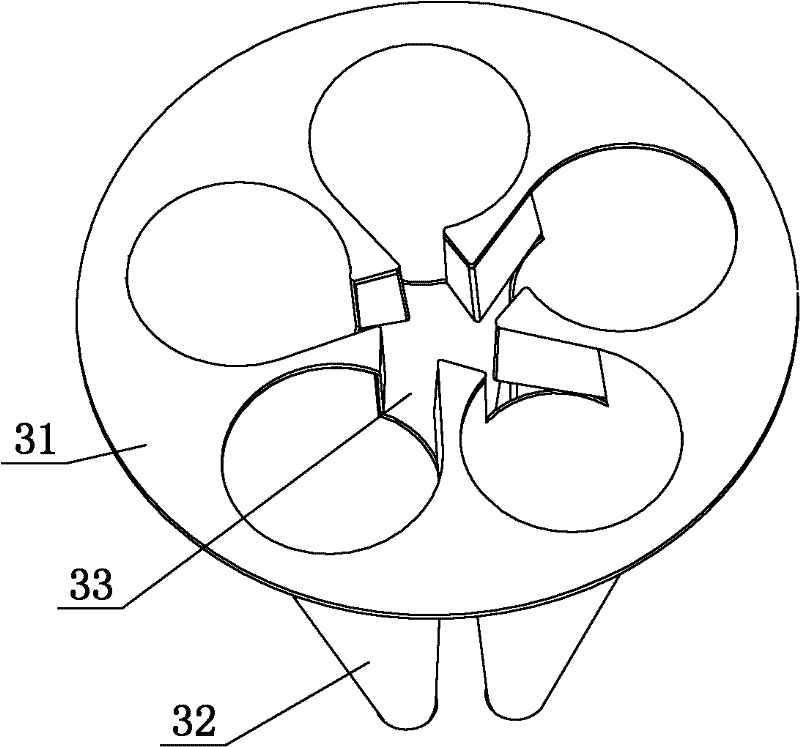

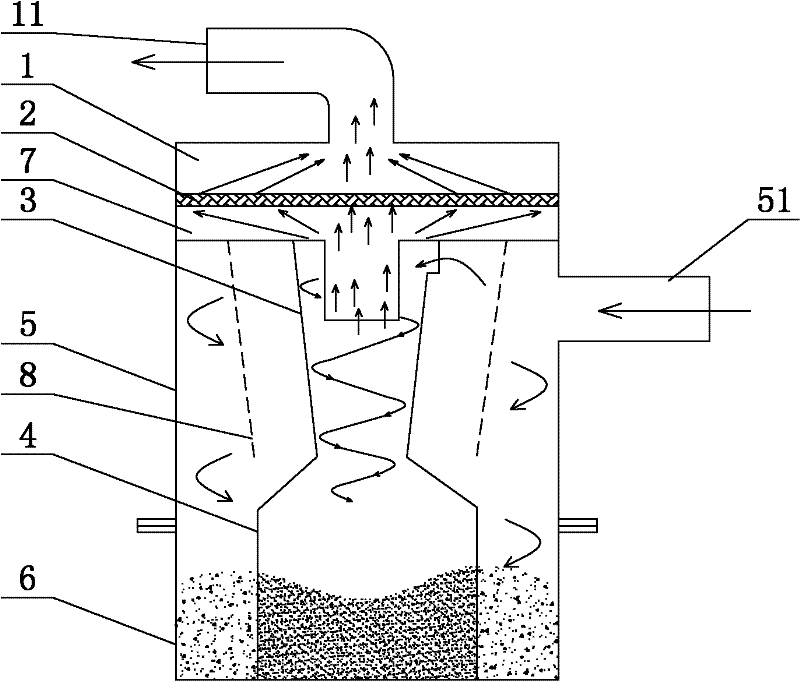

[0017] refer to Figure 1 to Figure 4 It is an embodiment of the multiple cyclone separation type filter device of the present invention, and the multiple cyclone separation type filter device includes a filter barrel cover 1, a filter screen device 2, a filter screen seat 7, an inner cyclone device 3, an inner dust collection bucket 4, and a filter bucket 5 , the outer dust collection barrel 6, the filter barrel cover 1 is covered on the filter barrel 5, the outer dust collection barrel 6 is arranged at the bottom of the filter barrel 5, the filter barrel cover 1 is provided with an air outlet pipe 11, the The side wall of the filter barrel 5 is provided with an air inlet pipe 51, and the filter barrel 5 is successively provided with a filter screen device 2, a filter screen seat 7, an inner cyclone device 3, and an inner dust collection bucket 4 from top to bottom, such as figure 2 As shown, the inner cyclone device 3 includes a cyclone flange 31 and a cyclone cone 32. Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com