Upward in and out basket type extraction automatic feeding and discharging system and process

An automatic feeding and discharging system technology, applied in transportation, packaging, loading/unloading, etc., can solve problems such as difficult slag discharge, limited production scale and production capacity, and unsafety, so as to avoid human pollution and reduce manual intervention , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

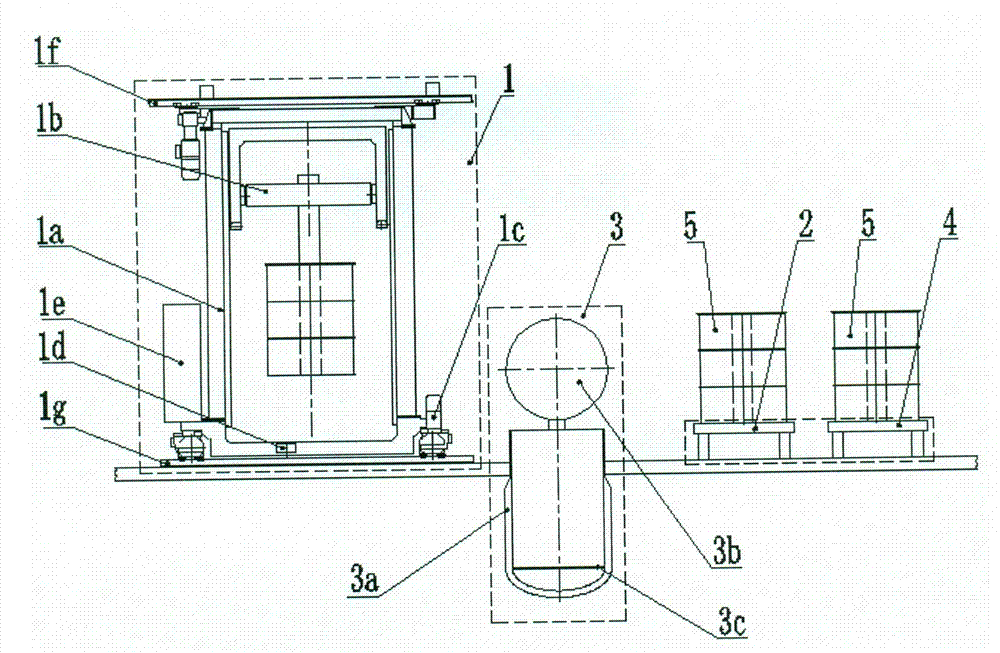

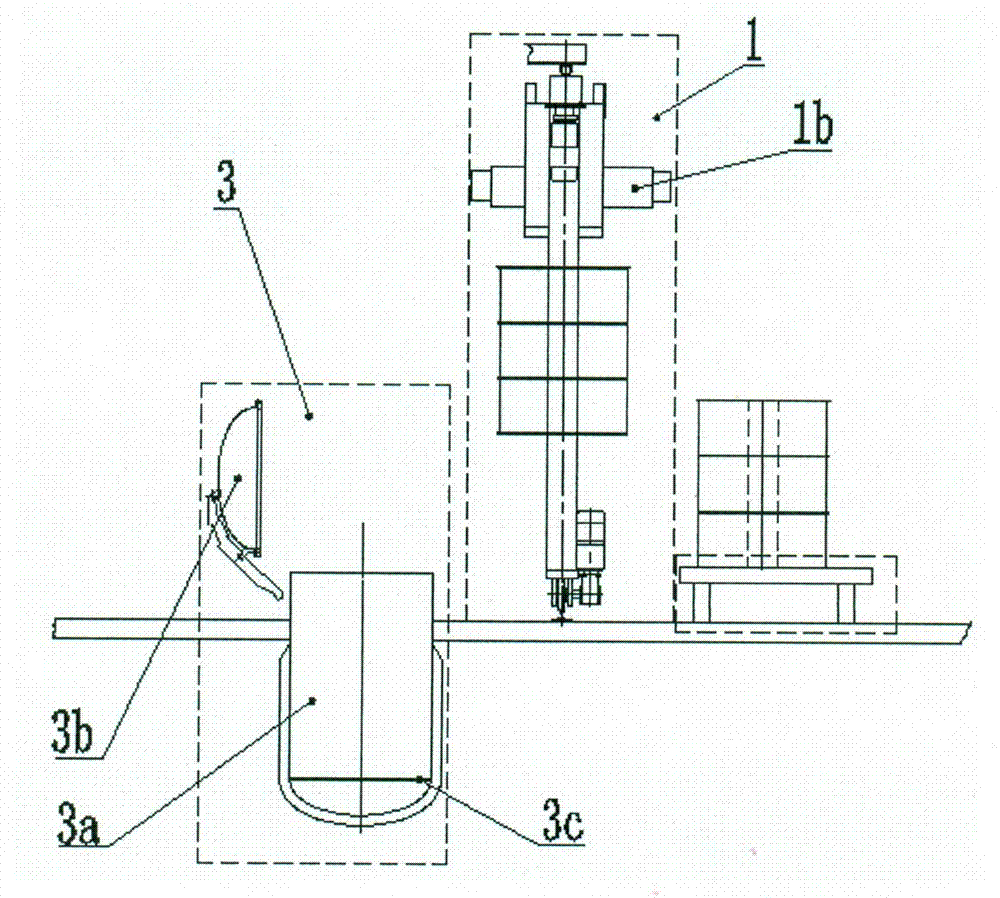

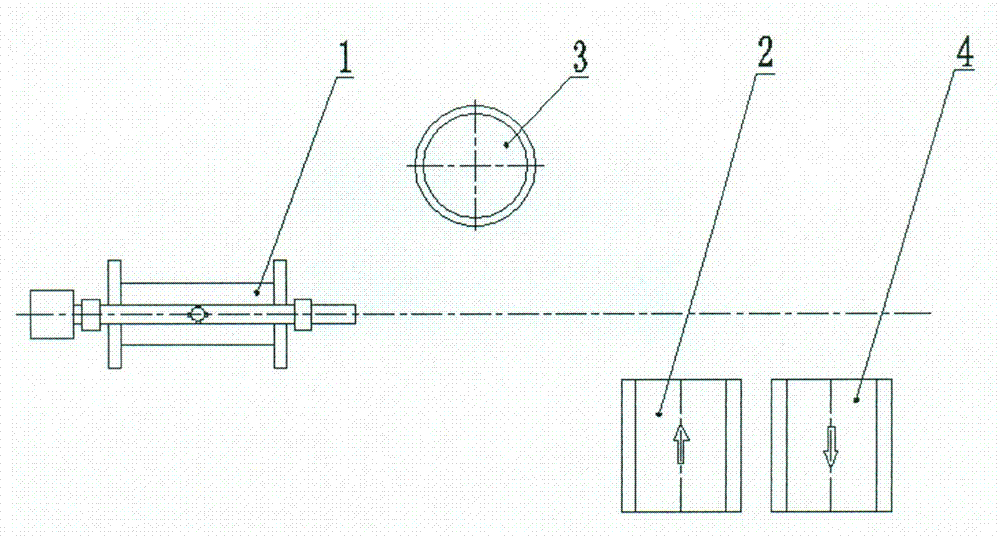

[0026] As shown in Figure l, figure 2 , image 3 As shown, the system of the present invention includes an extraction tank 3, a material basket 5 that can be placed in the extraction tank, an inlet platform 2 and an outlet platform 4 for turnover and placement of the material basket, and can be moved to the inlet platform 2 and the outlet platform 4 and the extraction tank Beside, the automatic feeding cart 1 that transfers the material basket obtained from the entrance platform and puts it in from the top of the extraction tank, or takes out the material basket from the top of the extraction tank and transfers it to the exit platform. One or more extraction tanks can be installed, but in large-scale modern production, more than one is usually installed. Such as Figure 4 As shown, two rows of extraction tanks 3 are arranged along both sides of the automatic feeding car 1 . The front end of the entrance platform 2 is docked with the automatic feeding vehicle 1, and the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com