Calibration method for multi-robot system base coordinate system possessing cooperation relation

A base coordinate system and multi-robot technology, applied in the field of industrial robots and flexible manufacturing systems, can solve the problems of calibration method steps and accuracy differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

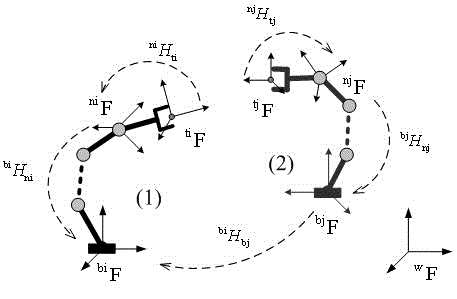

Method used

Image

Examples

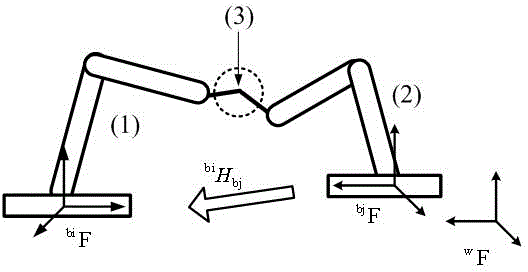

Embodiment Construction

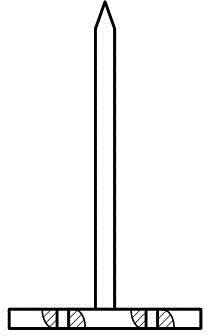

[0057] Taking the dual-robot collaborative system as an example, the hardware basis for realizing the present invention is as follows: Figure 5 shown. Figure 5 1 is a robot , 2 is a robot , 3 is the calibration finger, 4 is the robot controller, 5 is the robot The controller, 6 is the coordination controller, and 7 is the collaborative system teaching box. Among them, the controllers of each robot have installed joint position sensors and can complete the robot's forward kinematic transformation, and most industrial robots meet this requirement. The coordination controller 6 completes the planning and control of the collaborative motion among multiple robots, including tasks such as the calibration of the base coordinate system between the collaborative robots. Coordinating controller 6 is a functional component that can be physically realized by extending the system software on the existing robot controller. For the multi-robot collaborative system, the collaborat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com