Flexible magnetic strip and manufacturing method thereof

A flexible magnetic strip and manufacturing method technology, applied in the direction of inductance/transformer/magnet manufacturing, magnets, magnetic objects, etc., can solve the problems of short service life, easy falling off, magnetic influence of the magnetic strip, etc., and achieve improved service life and waterproof performance. Good and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

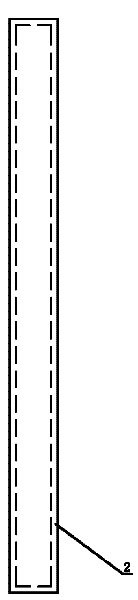

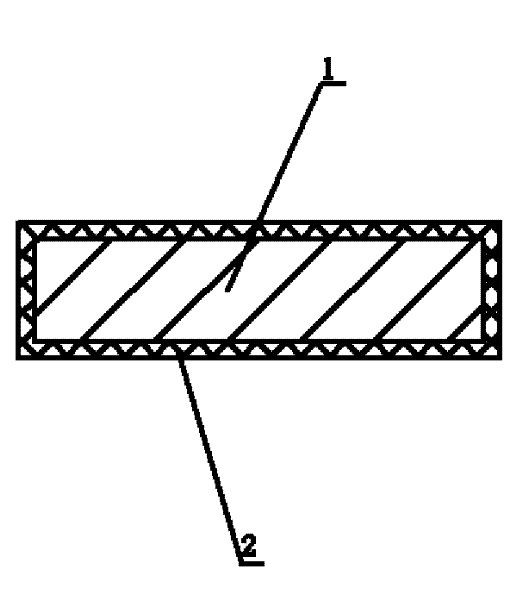

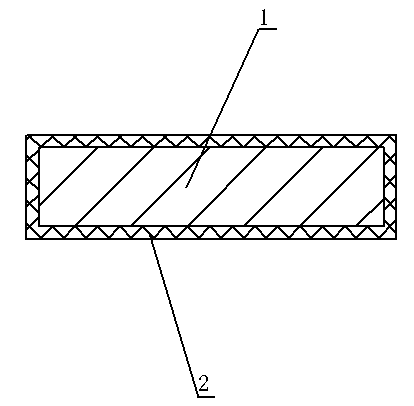

[0025] Such as figure 1 and figure 2 The shown flexible magnetic strip includes a flexible magnetic strip body 1, and a flexible protective sheath 2 made of a heat-shrinkable material is covered on the flexible magnetic strip body 1, and the flexible protective sheath 2 is closely attached to the flexible magnetic strip body 1. superior. The flexible protective sheath 2 is a rubber sheath, a plastic sheath or a rubber-plastic sheath.

[0026] The manufacturing method steps of manufacturing above-mentioned flexible magnetic strip are as follows.

[0027] (1) The magnetic powder is bonded into a flexible magnetic strip body 1 .

[0028] (2) Put the flexible protective cover 2 made of heat-shrinkable material on the flexible magnetic strip body 1 .

[0029] (3) Heating the semi-finished product formed in the above step (2). During the heating process, the flexible protective cover 2 undergoes thermal shrinkage deformation and is attached to the flexible magnetic strip body, ...

no. 2 approach

[0033] Such as figure 1 and figure 2 The shown flexible magnetic strip includes a flexible magnetic strip body 1, and a flexible protective sheath 2 made of a heat-shrinkable material is covered on the flexible magnetic strip body 1, and the flexible protective sheath 2 is closely attached to the flexible magnetic strip body 1. superior. The flexible protective cover 2 is made of heat-shrinkable PE, heat-shrinkable PP, heat-shrinkable PVC, heat-shrinkable ABS, heat-shrinkable EVA, heat-shrinkable PET or heat-shrinkable silicone.

[0034] The manufacturing method steps of manufacturing above-mentioned flexible magnetic strip are as follows.

[0035] (1) The magnetic powder is bonded into a flexible magnetic strip body 1 .

[0036] (2) Put the flexible protective cover 2 made of heat-shrinkable material on the flexible magnetic strip body 1 .

[0037] (3) Heating the semi-finished product formed in the above step (2). During the heating process, the flexible protective cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com