Integrated reinforcement bar pre-binding forming die constructing method for bridge construction

A bridge construction and construction method technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of difficult to readjust misplaced steel bars, low work efficiency, labor and time-consuming, etc., to achieve improved work efficiency, high work work efficiency, positioning accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

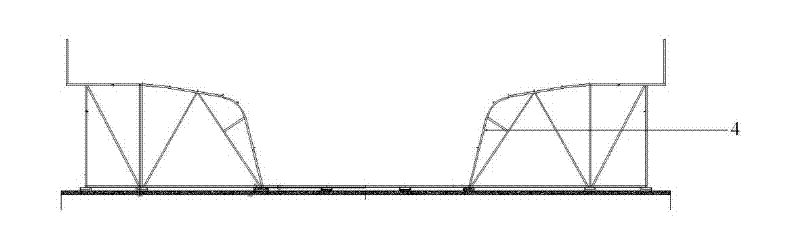

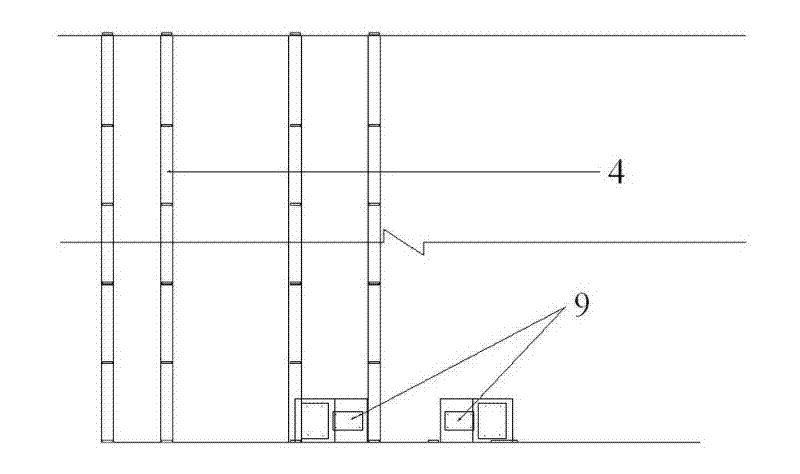

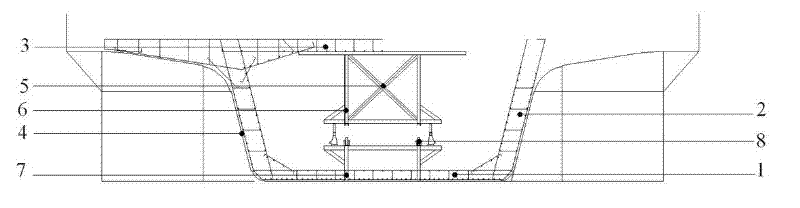

[0029] like Figure 1 to Figure 4 As shown, the general reference signs respectively represent: floor reinforcement cage 1, web reinforcement cage 2, bridge deck reinforcement cage 3, tying mold 4, false intima 5, telescopic support rod 6, weep hole model 7, anti-rail wheel 8. Support plate model 9.

[0030] The design purpose of the present invention is to provide an integral steel bar pre-binding method that facilitates the disassembly and assembly of the inner mold model based on the shortcomings of the existing pre-binding forming methods of steel bars. The general design concept is as follows:

[0031] First, bind the bottom plate reinforcement cage 1 and the web reinforcement cage 2 on a binding mold 4 for controlling the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com