Waterproofing ink-jet printing media and preparation method thereof

A technology of inkjet printing and media, applied in the direction of coating, etc., can solve the problems of reducing production efficiency, prolonging the preparation process, increasing labor costs, etc., and achieve the effects of improving production efficiency, shortening the preparation process, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

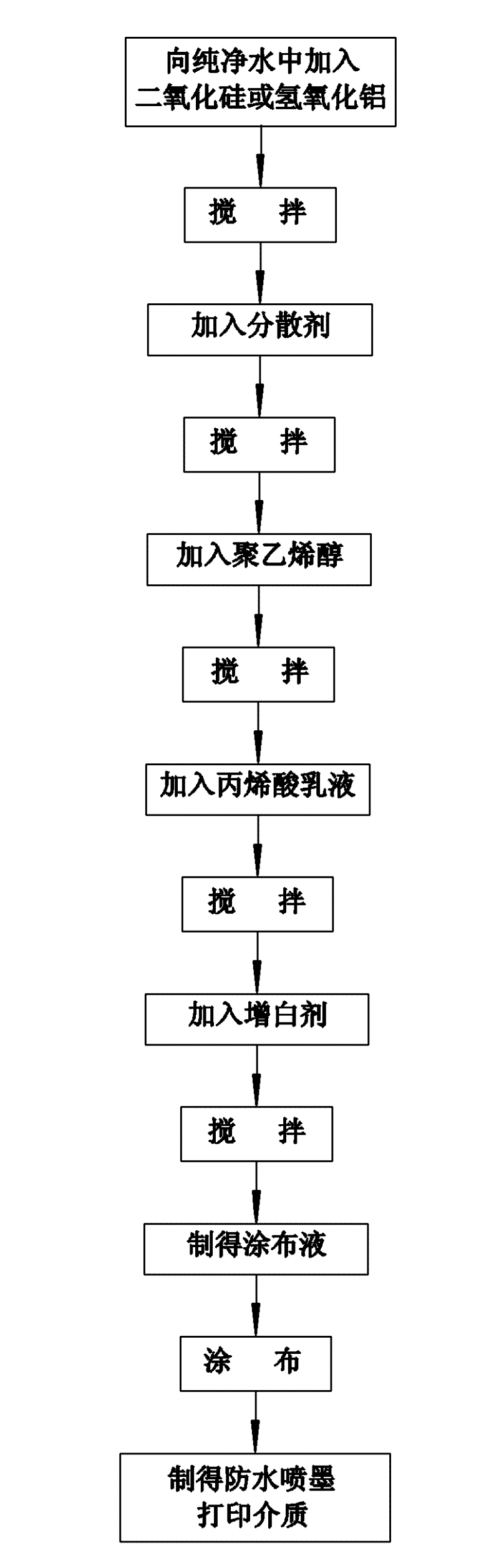

Image

Examples

Embodiment 1

[0018] Waterproof inkjet printing medium, including a sheet-shaped waterproof substrate, the sheet-shaped waterproof substrate is coated with a coating liquid on one side to form an ink-absorbing waterproof layer, and the coating liquid is prepared by dissolving the following raw materials and additives in purified water Preparation: silicon dioxide, 38 parts by weight; polyvinyl alcohol, 3 parts by weight; cationic acrylic acid, 60 parts by weight; dispersant, 0.1 parts by weight; whitening agent, 0.1 parts by weight.

[0019] As shown in the accompanying drawing, the preparation method of the above-mentioned waterproof inkjet printing medium comprises the following steps

[0020] 1.) Preparation of coating liquid: first add 38 parts by weight of silicon dioxide to 300 parts by weight of pure water, and stir continuously to disperse it. During the dispersion process, add 0.1 parts by weight of dispersant and disperse for 40 minutes to make Silica is evenly dispersed; then add...

Embodiment 2

[0022] Embodiment 2: Embodiment 2 is basically the same as Embodiment 1, the difference is that

[0023] The coating solution in this embodiment is prepared from the following raw materials and auxiliary agents: aluminum hydroxide, 25 parts by weight; polyvinyl alcohol, 5 parts by weight; cationic acrylic acid, 20 parts by weight; dispersant, 0.15 parts by weight; Brightener, 0.05 parts by weight.

[0024] The steps of preparing the coating solution in this embodiment are: firstly add 25 parts by weight of aluminum hydroxide to 200 parts by weight of pure water, and stir continuously to disperse it. During the dispersion process, add 0.15 parts by weight of a dispersant to disperse 30 minutes to make the aluminum hydroxide dispersed evenly; then add 5 parts by weight of polyvinyl alcohol and continue to stir; then add 20 parts by weight of cationic acrylic emulsion, mix and stir for 50 minutes, add 0.05 parts by weight of whitening agent, continue to stir evenly Thereafter, a...

Embodiment 3

[0025] Embodiment three: Embodiment three is basically the same as embodiment two, the difference is that

[0026] The coating solution in this embodiment is prepared from the following raw materials and auxiliary agents: aluminum hydroxide, 10 parts by weight; polyvinyl alcohol, 2 parts by weight; cationic acrylic acid, 40 parts by weight; dispersant, 0.05 parts by weight; Brightener, 0.15 parts by weight.

[0027] The steps of preparing the coating solution in this example are as follows: first add 10 parts by weight of aluminum hydroxide to 250 parts by weight of pure water, and stir continuously to disperse it. During the dispersion process, add 0.05 parts by weight of a dispersant to disperse 50 minutes to make aluminum hydroxide dispersed evenly; then add 2 parts by weight of polyvinyl alcohol and continue to stir; then add 40 parts by weight of cationic acrylic emulsion, mix and stir for 70 minutes, add 0.15 parts by weight of whitening agent, continue to stir evenly T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com