Interlocking control device of wheel tug assembling line and vehicle-receiving off-line equipment and collocation method

An interlocking control and final assembly line technology, applied in the direction of motor vehicles, transportation and packaging, can solve the problems of tail collision, operation quality failure of plate conveyor chain 6, affecting normal operation, etc., to avoid accidents and avoid personal safety accidents. , the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

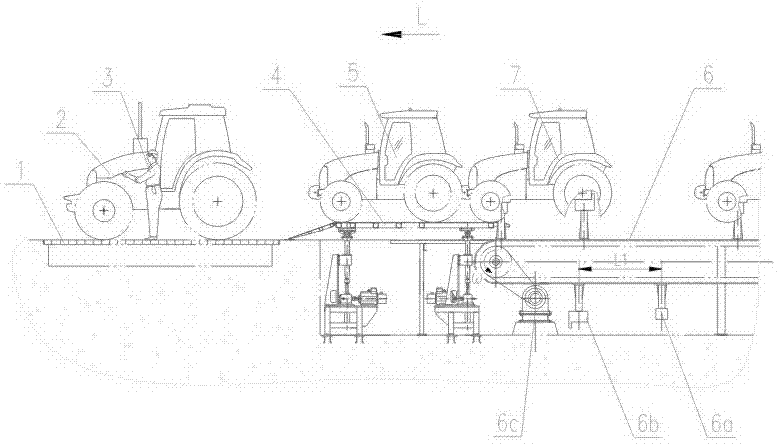

[0079] Embodiment 1, the solution to the problem of the collision between the wheeled trailer to be off-line after final assembly on the assembly line plate conveyor chain and the wheeled trailer on the receiving platform in the receiving and off-line platform assembly.

[0080] Depend on Figure 15 , Figure 16 , Figure 17 It is known that the guided ejector rod assembly 10a in the double fulcrum lifting assembly 10 and the guided A ejector rod assembly / guided B ejector rod in the single fulcrum A lifting assembly / single fulcrum B lifting assembly "8 / 9" Under the common support of the components " 8a / 9a ", there is an F wheel drag 34 on the car receiving platform of its car receiving and off-line platform assembly 4 .

[0081] Now, the light beam β sent by the light emitter in the diffuse reflection photoelectric switch 21 in the diffusion reflection photoelectric sensor assembly 15 is blocked by the obstruction F wheel 34 when passing by, and part of the light is reflecte...

Embodiment 2

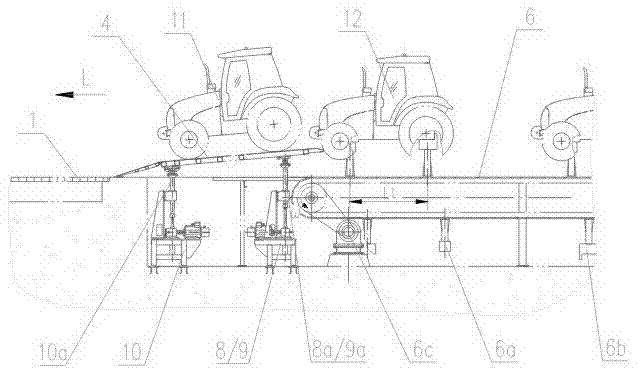

[0085] Embodiment 2, the solution to the problem of the rear end of the tilting car receiving platform colliding with the wheel drag after final assembly on the assembly line plate type conveyor chain.

[0086] Depend on Figure 18It is known that there is a wheel trailer F34 on the receiving platform of the off-line platform assembly 4, and the guide A push rod assembly / Under the action of the jacking force of the guide rod assembly "8a / 9a", the two rollers with the guide rod assembly 10a in the double fulcrum lifting assembly 10 start to rotate as double fulcrums, and force the rollers on it to Towing the F34 can slide down the slope by itself according to its own gravity;

[0087] At this moment, when the car receiving platform tilts to the angle at which the F wheeled trailer 34 begins to slide, the light beam β sent by the light emitter of the diffuse reflective photoelectric switch 21 in the diffuse reflective photoelectric sensor assembly 15 can still be blocked by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com