High-milling type mill disk and high-milling type impregnating disk mill

A disc refiner and grinding disc technology, applied in textiles and papermaking, pulp beating/refining methods, fiber raw material processing, etc., can solve problems such as unstable machine operation, clogging, and poor grinding and dispersion of fine fiber bundles. Achieve the effect of low power consumption, small wear and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

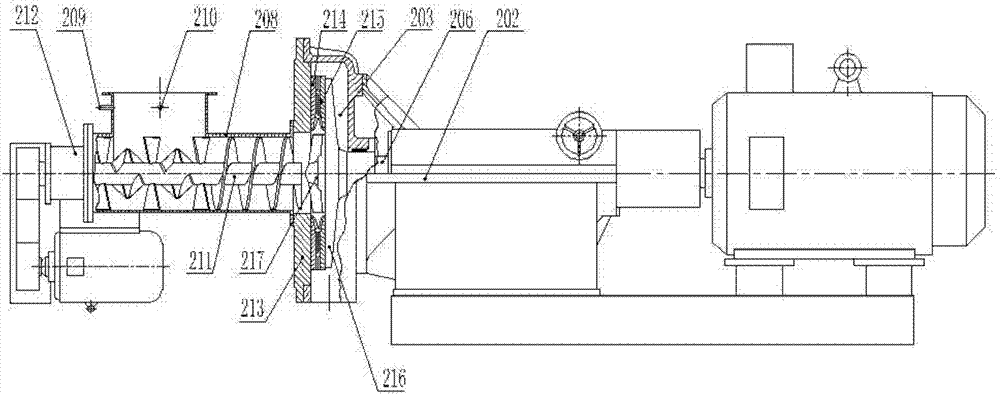

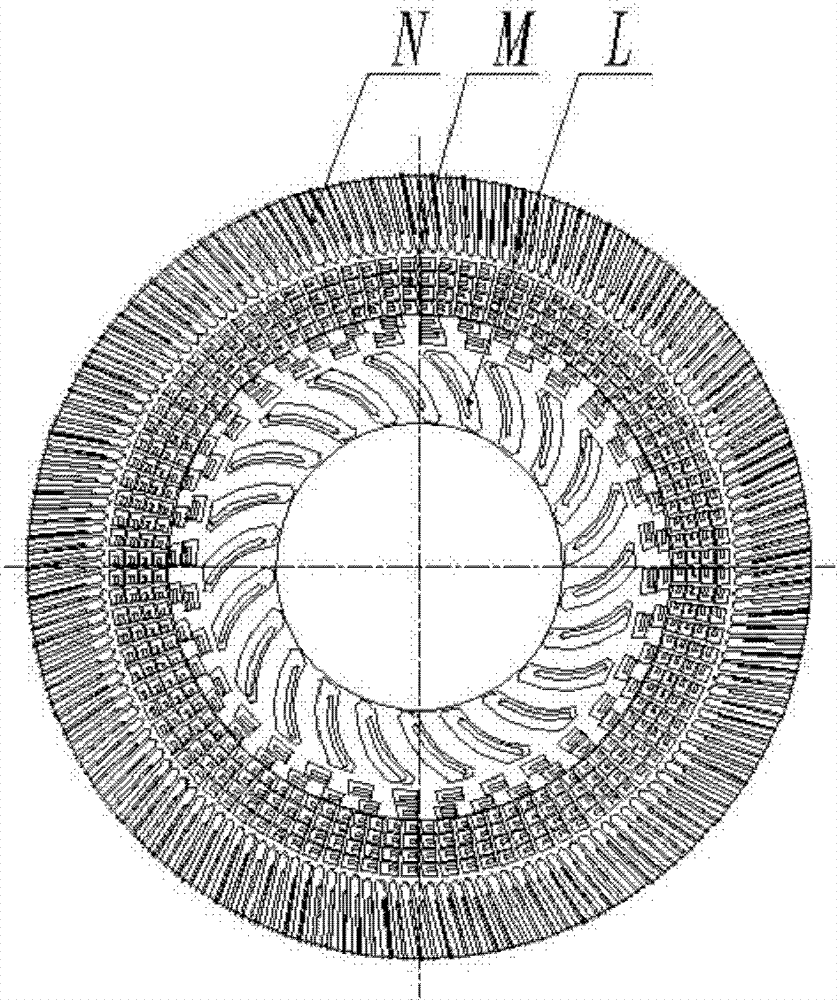

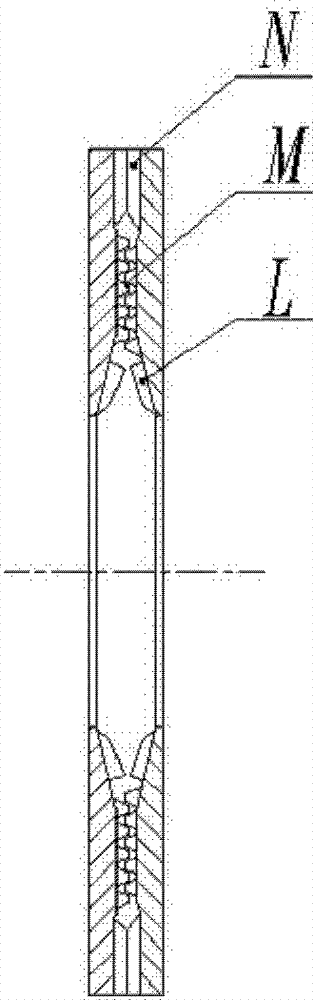

[0011] The high-grinding type immersion disc mill provided by the present invention has a casing comprising a feed channel 208, a disc mill chamber 203 and a main shaft bearing frame 202, and the fixed mill disc 214 is fixed on the cover 213 on one side of the disc mill chamber, and The channel 208 is connected to the disc grinding chamber 203 through the central opening of the fixed grinding disc 214. The feeding screw 211 is supported by the bearing 212 in the feeding channel 208, and the main shaft 206 is supported by the horizontal rotation of the bearing frame 202. The feeding screw 211 and the main shaft 206 Coaxial, the turntable 216 is fixedly installed on the shaft end where the main shaft 206 penetrates into the disc grinding chamber 203, the turntable 216 is fixed on the shaft end of the main shaft by the locking wing wheel 217 which plays the role of distributing materials, and the moving grinding disc 215 is fixedly installed on the On the rotating disk 216, the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com