Integrally moving and cluster well switching device of drilling machine

A technology for switching devices and cluster wells, applied to drilling equipment, earthwork drilling, drilling equipment and methods, etc., can solve the problems of transportation weight, difficult transportation shape, complex drilling rig structure, difficult production and maintenance, etc., to achieve Improve the utilization rate of equipment and transportation efficiency, reduce the installation intensity of workers, and reduce the number of transportation vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Cluster Well Drilling

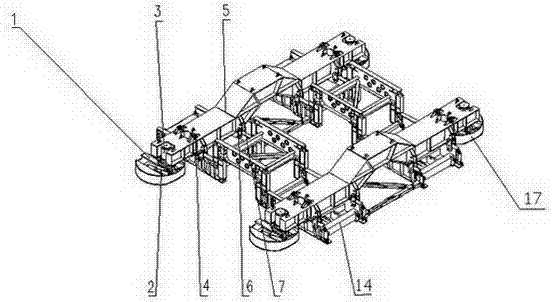

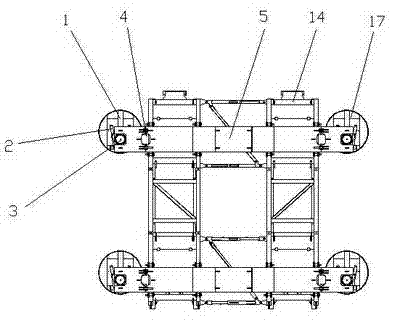

[0028] see figure 1 , figure 2 and Image 6 , First, connect the fixed lugs 7 on the two transport beams 5 with the rig base frame 14 with the fixing pins 6, so that the two transport beams 5 and the drilling rig base frame 14 become a whole, and the four transport beams 5 at both ends of the The cluster well device is connected with the transport beam 5 by the lifting cylinder 3 with the sliding seat. When the drilling rig moves forward as a whole, the four lifting cylinders 3 with sliding seats are pushed out at the same time, so that the supporting disc 17 is supported to the ground, and the base frame 14 of the drilling rig is lifted up at the same time, and then the four are installed in the supporting disc 17 At the same time, the stepping oil cylinder 2 is extended, so that the lifting oil cylinder 3, which is sleeved on the slide rail 1 and connected with the sliding seat, drives the transport beam 5 and the drilling rig base frame 14...

Embodiment 2

[0030] The overall movement of the drilling rig

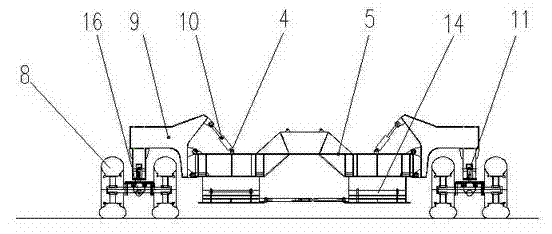

[0031] see image 3 , Figure 4 and Figure 5 First, connect the connecting lug 18 on the upper part of the hauling tire mounting frame 9 of the whole machine with the lifting cylinder 10, and the other end of the jacking cylinder 10 is connected with the connecting lug 4 on the transport beam 5, and the whole hauling tire The axle mounting seat 11 at the bottom of the mounting frame 9 is connected with the axle 16, so that the whole machine hauling tire mounting frame 9, the axle 16 and the tire 8 are integrated (see Figure 4 ), at this time the tire 8 and the drilling rig base frame 14 are arranged vertically. When the drilling rig needs to be moved as a whole, the jacking cylinder 10 starts to lift. With the extension of the cylinder, the tire 8 slowly rolls close to the wellhead, and the transport beam 5 is also lifted. At this time, the hauling tire of the whole machine is installed The middle connecting lug plate 19 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com