Calcium sulfate whisker modified polystyrene composite material and preparation process thereof

A technology of calcium sulfate whiskers and polystyrene, which is applied in the field of polystyrene composite materials and its preparation technology, can solve the problems of poor heat resistance, low tensile strength of impact-resistant polystyrene, and limited use, and achieve tensile strength High tensile strength and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

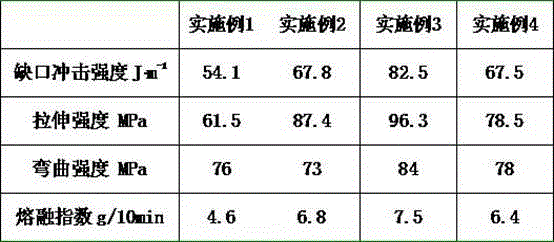

Examples

Embodiment 1

[0015] The raw material weight ratio of calcium sulfate whisker modified polystyrene composite material in this example: 100 parts of high-impact polystyrene (HIPS), 20 parts of calcium sulfate whisker, 0.2 part of primary antioxidant, 1010 of auxiliary antioxidant Agent DLTP 0.2 parts, lubricant Hst 2 parts, silane coupling agent KH550 1 part.

[0016] Preparation:

[0017] (1) Activate calcium sulfate whiskers and silane coupling agent KH550 in a high-speed mixer for 10 minutes to obtain modified calcium sulfate whiskers; the modified calcium sulfate whiskers have an aspect ratio of 13 and a diameter of 0.8 μm ;

[0018] (2) Add the impact-resistant polystyrene, main antioxidant 1010, auxiliary antioxidant DLTP, and lubricant Hst into a high-speed mixer, mix at 50°C for 7 minutes, and dry; obtain impact-resistant polystyrene A mixture of ethylene, primary antioxidant 1010, secondary antioxidant DLTP, lubricant Hst and modified calcium sulfate whiskers;

[0019] (3) The mi...

Embodiment 2

[0022] The raw material weight ratio of the calcium sulfate whisker modified polystyrene composite material in this example: 100 parts of high-impact polystyrene (HIPS), 30 parts of calcium sulfate whisker, 0.1 part of the main antioxidant, and 0.1 part of the auxiliary antioxidant Agent DLTP 0.1 parts, lubricant Hst 2 parts, silane coupling agent KH550 2 parts.

[0023] Preparation:

[0024] (1) Activate calcium sulfate whiskers and silane coupling agent KH550 in a high-speed mixer for 10 minutes to obtain modified calcium sulfate whiskers; the obtained calcium sulfate whiskers have an aspect ratio of 15 and a diameter of 1 μm;

[0025] (2) Add the impact-resistant polystyrene, main antioxidant 1010, auxiliary antioxidant DLTP, and lubricant Hst into a high-speed mixer, mix at 50°C for 7 minutes, and dry; obtain impact-resistant polystyrene A mixture of ethylene, primary antioxidant 1010, secondary antioxidant DLTP, lubricant Hst and modified calcium sulfate whiskers;

[00...

Embodiment 3

[0029] The raw material weight ratio of the calcium sulfate whisker modified polystyrene composite material in this example: 100 parts of high-impact polystyrene (HIPS), 35 parts of calcium sulfate whisker, 0.3 part of primary antioxidant, 1010 of auxiliary antioxidant Agent DLTP 0.3 parts, lubricant Hst 3 parts, silane coupling agent KH550 1 part.

[0030] Preparation:

[0031] (1) Activate calcium sulfate whiskers and silane coupling agent KH550 in a high-speed mixer for 10 minutes to obtain modified calcium sulfate whiskers; modified calcium sulfate whiskers have an aspect ratio of 20 and a diameter of 0.5 μm;

[0032] (2) Add the impact-resistant polystyrene, main antioxidant 1010, auxiliary antioxidant DLTP, and lubricant Hst into a high-speed mixer, mix at 50°C for 7 minutes, and dry; obtain impact-resistant polystyrene A mixture of ethylene, primary antioxidant 1010, secondary antioxidant DLTP, lubricant Hst and modified calcium sulfate whiskers;

[0033] (3) The mixt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com