Triangulation system for flat machine

A cam system and cam technology, applied in the field of cam systems used in flat knitting machines, can solve problems such as the inability to use the cam parts of the needle cam, achieve the effects of shortening knitting time, shortening adjustment time, and improving operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

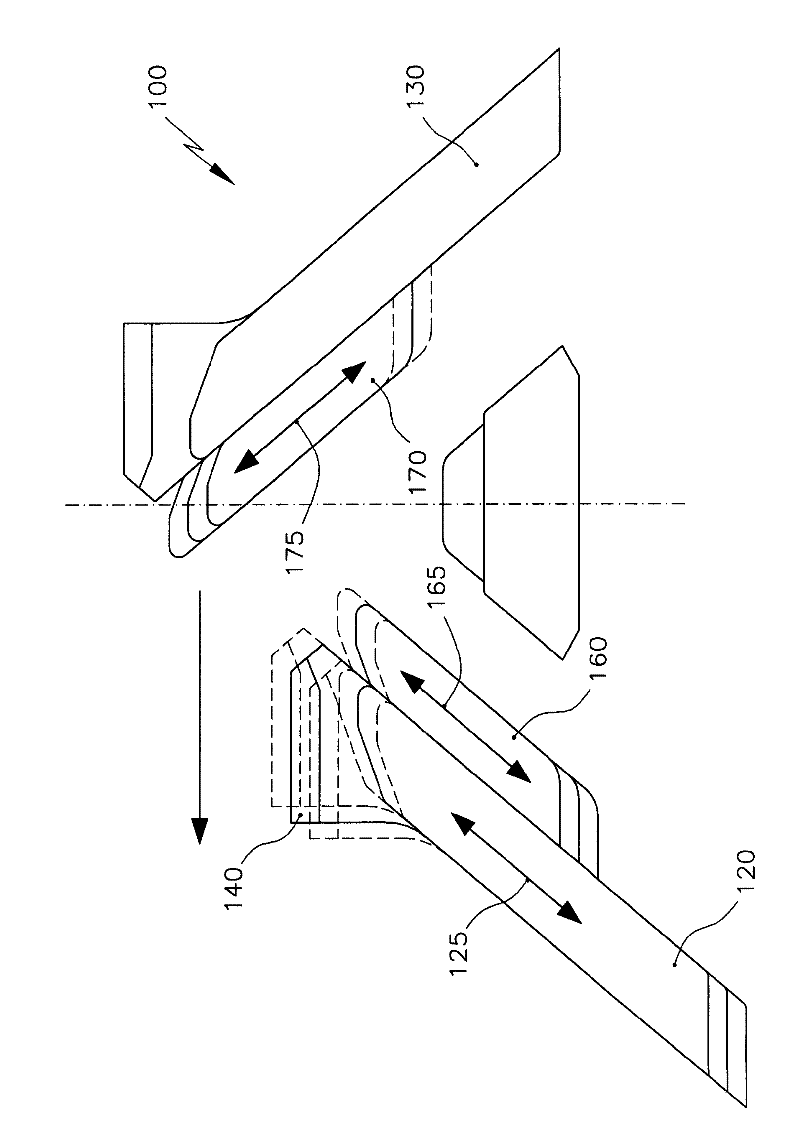

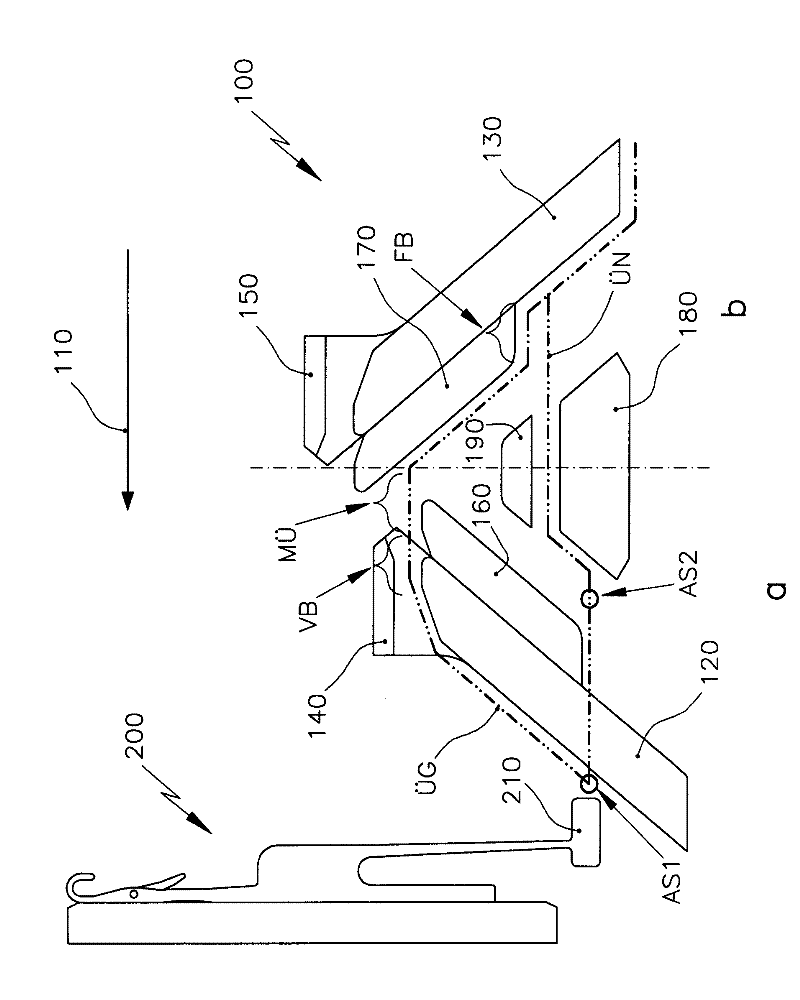

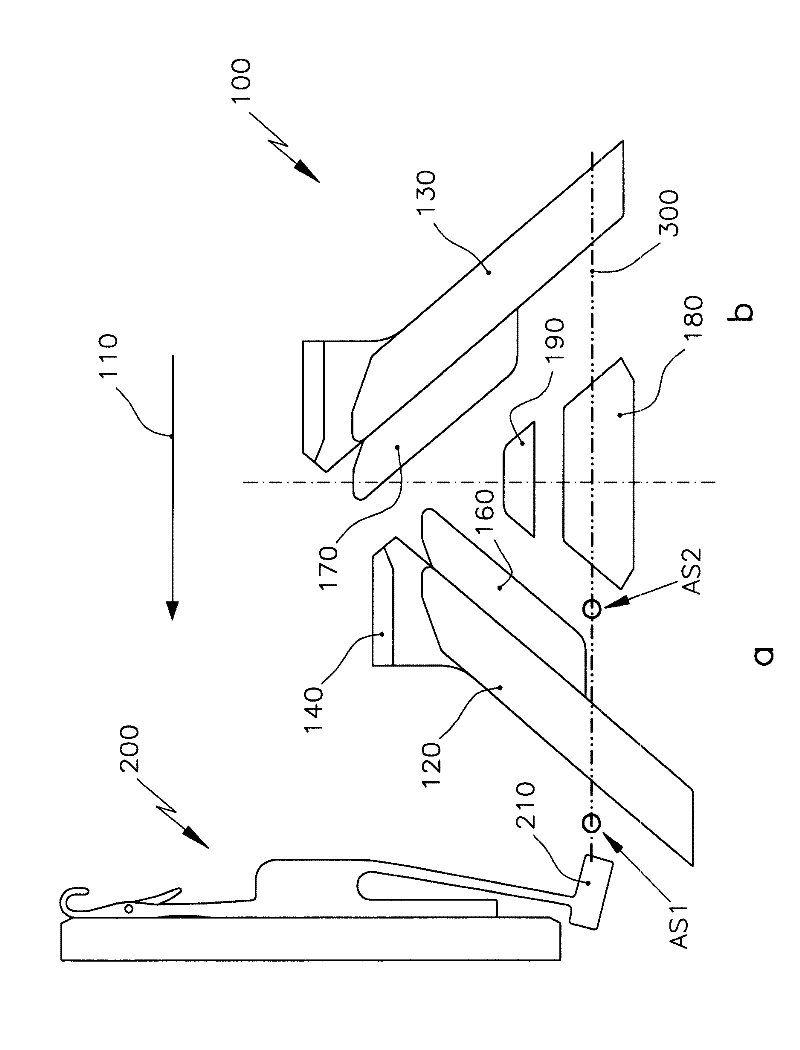

[0027] figure 1 a, 2a, 4a and 5a are schematic illustrations of a knitting needle 200 having a drive foot 210 arranged at its end, which is arranged on an elastic section 220 of a needle shank 230 so as to be pivotably limited. The needles 200 are located in the needle bed 250 . The illustrated needle 200 is exemplary only. It is also possible to use the needle cam shown in the figures to actuate other needle configurations with drive feet that are translatable between a position that is lowered into the needle bed and a position that is raised above the needle bed.

[0028] exist figure 1 In a, the driving foot 210 of the knitting needle 200 is not touched. In this state, the driving foot does not protrude from the needle bar 230, and thus cannot be connected with the figure 1 The needle cam 100 shown in b is engaged. The drive foot 210 thus passes the needle cam 100 during its movement along the horizontally extending line 300 indicated by the dotted line in the directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com