Method for cleaning space between inner and outer tubs of washing machine with flexible particles and washing machine capable of implementing same

A technology of flexible particles and washing machines, applied in the field of washing machines, can solve the problems of affecting the collection effect of lint, not considering the collection of lint, and the inability to wash the inner and outer barrel walls, etc., and achieve the effect of simple and feasible method, scientific design, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

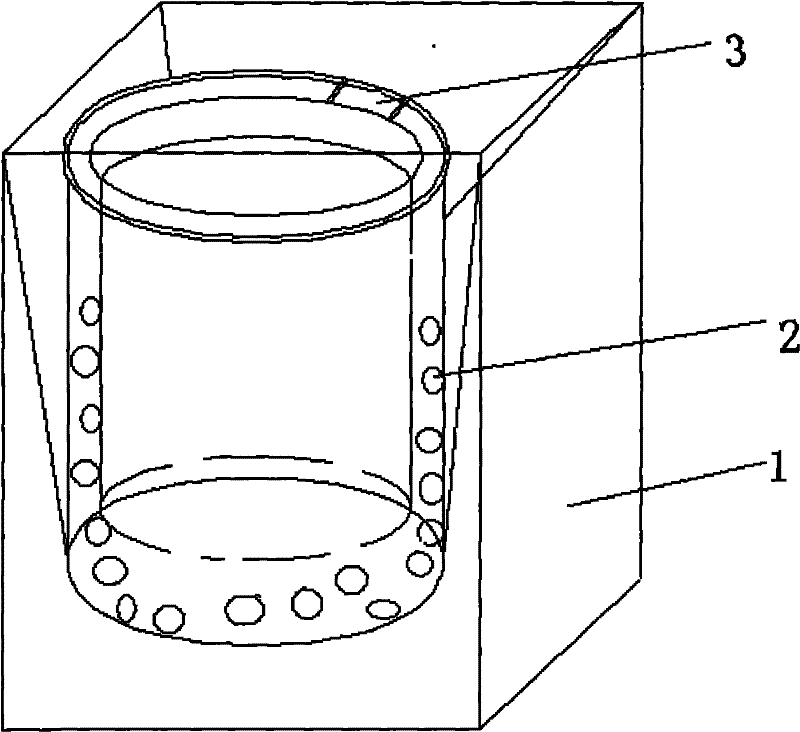

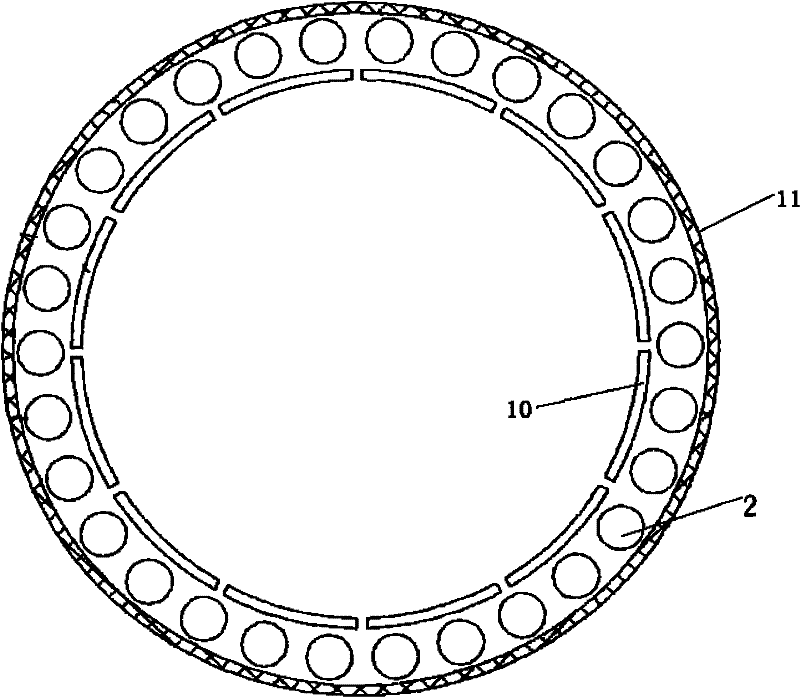

[0052] like figure 1 As shown, the washing machine 1 of the present invention includes a washing machine body and flexible particles 2 placed between the inner and outer tubs of the washing machine. The outer tub cover of the washing machine 1 is provided with an openable flexible particle input port 3 for placing flexible particles 2 whose width d is smaller than the distance D between the inner and outer tubs between the inner and outer tubs.

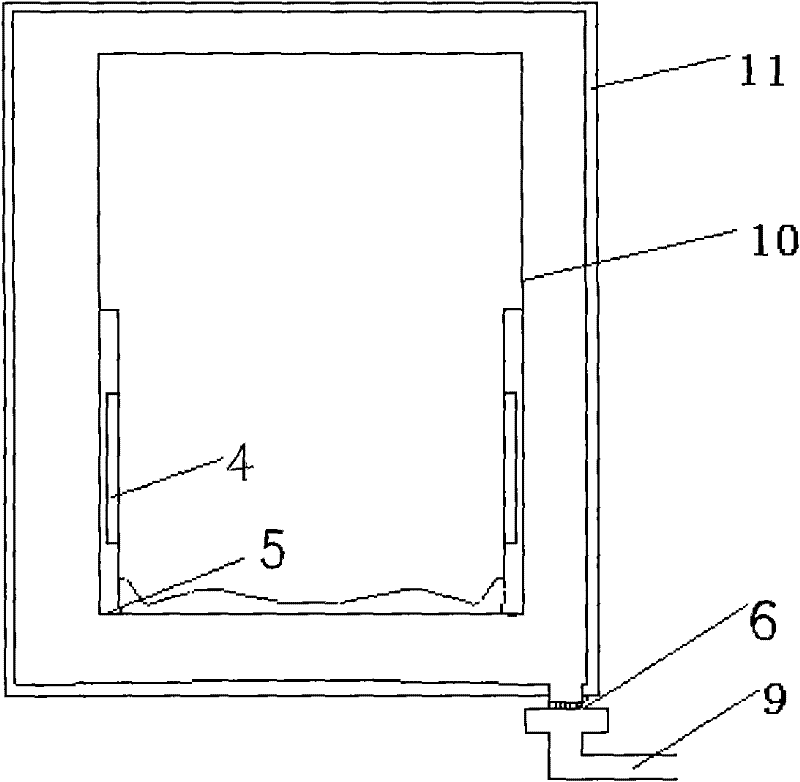

[0053] like figure 2 As shown, two lint filters 4 are provided on the pulsator wall of the washing machine 1. At the water inlet under the lint filter 4 of the present invention, a protruding strip structure 5 is provided to prevent the flexible particles 2 from being stuck in the lint filter. At the lower water inlet of device 4.

[0054] In addition, a network card 6 is provided at the entrance of the drainpipe 9 at the bottom of the outer tub 11 of the washing machine 1. When the washing process needs to be drained, the network ...

Embodiment 2

[0059] like figure 1 As shown, the washing machine 1 of the present invention includes a washing machine body and flexible particles 2 placed between the inner and outer tubs of the washing machine. The outer barrel cover of the washing machine 1 is provided with an openable flexible particle inlet 3 for placing flexible particles 2 smaller than the gap between the inner and outer barrels between the inner and outer barrels.

[0060] like figure 2 As shown, two lint filters 4 are provided on the pulsator wall of the washing machine 1. At the water inlet under the lint filter 4 of the present invention, a protruding strip structure 5 is provided to prevent the flexible particles 2 from being stuck in the lint filter. At the lower water inlet of device 4.

[0061] In addition, a network card 6 is provided at the entrance of the drainpipe 9 at the bottom of the outer tub 12 of the washing machine 1. When the washing process needs to be drained, the network card 6 is in a close...

Embodiment 3

[0066] like figure 1 As shown, the washing machine 1 of the present invention includes a washing machine body and flexible particles 2 placed between the inner and outer tubs of the washing machine. The outer barrel cover of the washing machine 1 is provided with an openable flexible particle inlet 3 for placing flexible particles 2 smaller than the gap between the inner and outer barrels between the inner and outer barrels.

[0067] like figure 2 As shown, there are two lint filters 4 on the pulsator wall of the washing machine 1, and the water inlet under the lint filter 4 of the present invention is provided with a convex mesh structure to prevent the flexible particles 2 from being stuck in the lint filter 4 at the water inlet.

[0068] In addition, a network card 6 is provided at the entrance of the drainpipe 10 at the bottom of the outer tub 12 of the washing machine 1. When the washing process needs to be drained, the network card 6 is in a closed state to prevent th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com