Reinforced concrete hollow floor

一种钢筋混凝土、空心楼板的技术,应用在楼板、建筑、建筑构件等方向,能够解决楼板抗渗性能不佳、连接不紧密、楼板整体性不好等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

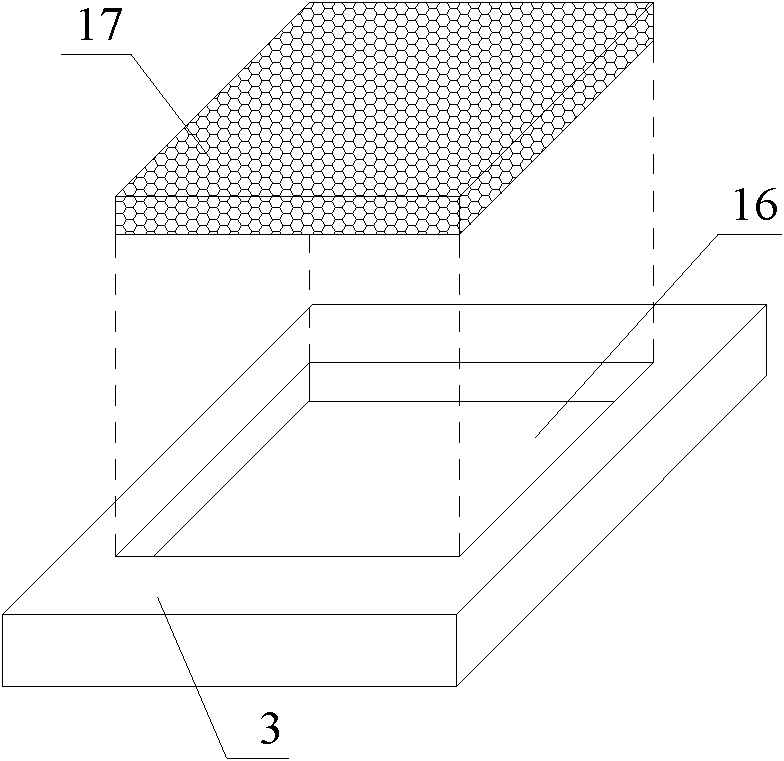

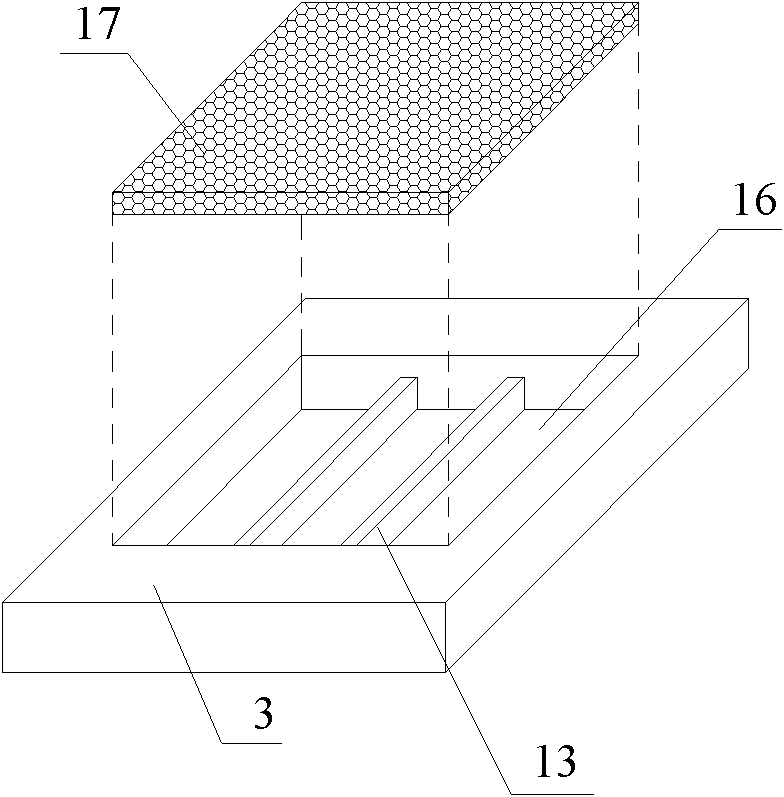

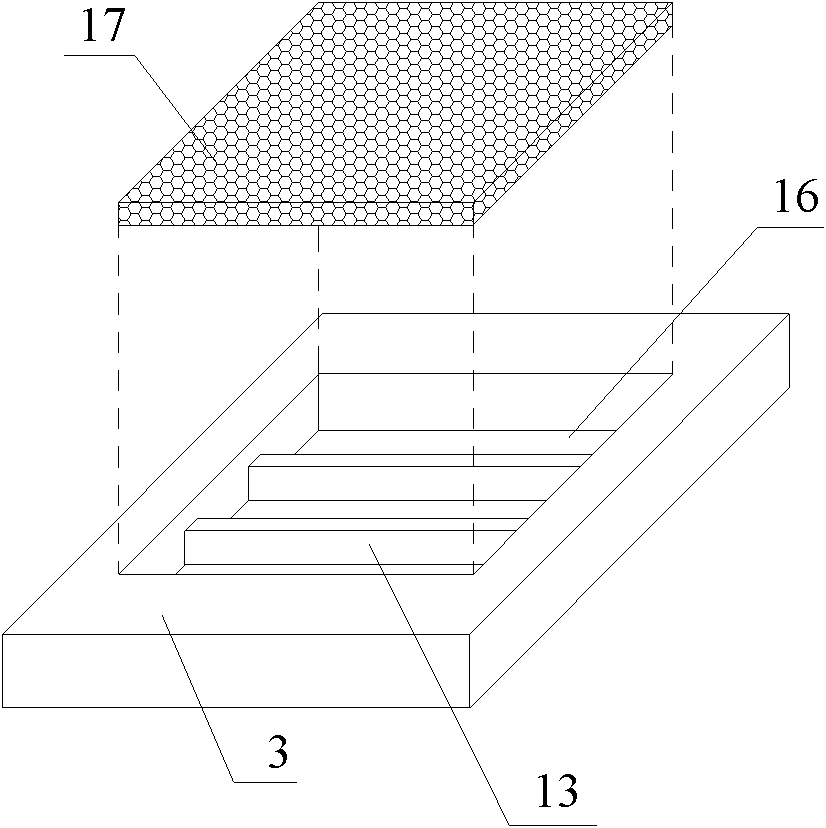

[0020] The invention is attached Figure 1-9 As shown, a reinforced concrete hollow floor slab includes cast-in-place dense ribs 1, prefabricated side walls 2, prefabricated bottom slab 3, and cast-in-place roof 4. The hollow floor slab consists of prefabricated side walls 2, prefabricated bottom The dense rib 1 forms a cavity 5, and the prefabricated floor 3 has a groove 16 on the top, and the groove 16 is filled with a lightweight material 17. figure 1 It is a schematic diagram of filling the light material 17 in the groove 16 of the prefabricated bottom plate 3 .

[0021] There are longitudinal ribs or transverse ribs or both longitudinal ribs and transverse ribs in the groove 16 of the prefabricated floor 3, and the ribs 13 are covered with lightweight materials 17. In this way, the weight of the prefabricated floor 3 is reduced, and the prefabricated floor can also be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com