Modified ultrasonic atomization warming method and novel warming ultrasonic atomization device

A new type of ultrasonic atomization technology, applied in the direction of treatment atomizers, water heaters, air heaters, etc., can solve the problem of only generating cold mist, and achieve the effect of thermal mist stabilization, enhancement effect, and reduction of discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

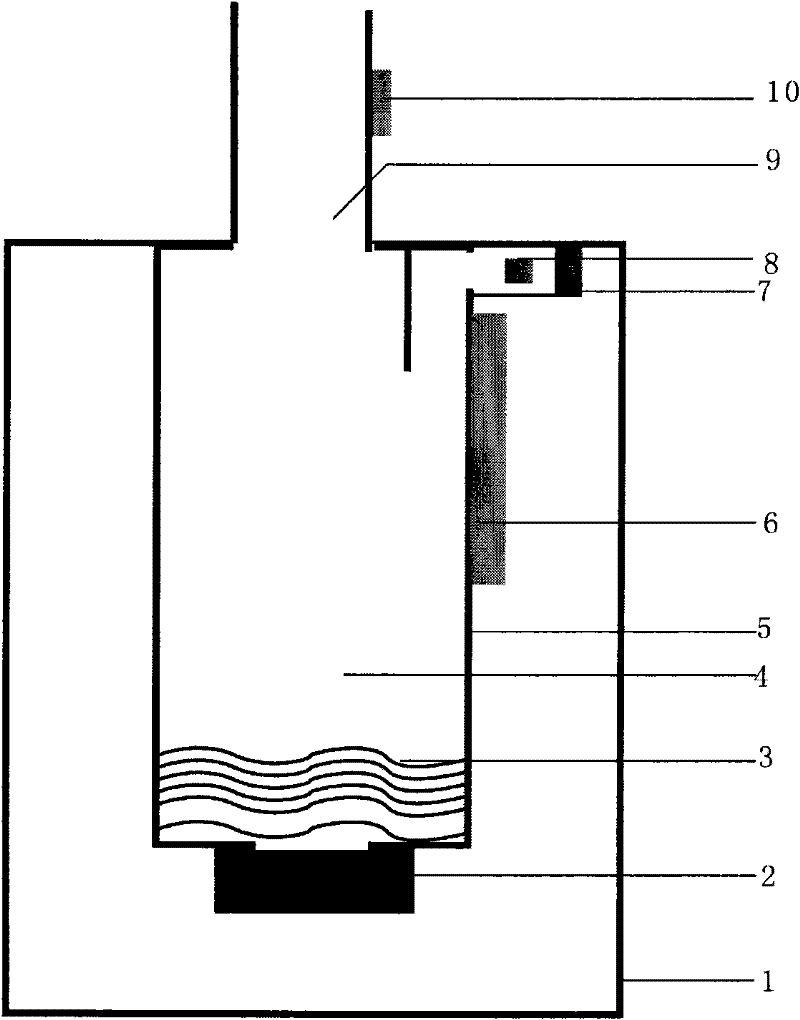

[0036] Example 1: In figure 1 Among them, the atomizing water tank (4) is made of aluminum casting, the heating heating element a (6) is a heating sheet, which is installed on the outer surface of the atomizing water tank wall (5), and the heating heating element b (8) is a self-constant temperature Heating sheet is installed on the blower fan (7) outlet end, and the mist outlet pipe (9) is made of aluminum casting, and the heating heating element c (10) is a heating film, which is installed on the outside wall of the mist outlet pipe (9). When in use, first add an appropriate amount of liquid to be atomized (3) into the atomizing water tank (4), start the machine, and the ultrasonic transducer (2) will work to generate mist, and the airflow generated by the fan (7) will flow the mist out. The mist pipe (9) flows out for treatment and beauty treatment.

Embodiment 2

[0037] Example 2: In figure 1 Among them, the atomizing water tank (4) is made of copper casting, and the heating element a (6) is a heating film, which is installed on the outer surface of the atomizing water tank wall (5), and the heating of the heating film is controlled by the loaded temperature control circuit , the heating heating element b (8) is a self-constant temperature heating sheet, which is installed on the outlet end of the fan (7). Warm heat. When in use, first add an appropriate amount of liquid to be atomized (3) into the atomizing water tank (4), start the machine, and the ultrasonic transducer (2) will work to generate mist, and the airflow generated by the fan (7) will flow the mist out. The mist pipe (9) flows out for treatment and beauty treatment.

Embodiment 3

[0038] Example 3: In figure 1 Among them, the atomizing water tank (4) is made of ordinary plastic, and no heating element is installed on the outer surface of the atomizing water tank wall (5). At the air outlet, the mist outlet pipe (9) is made of aluminum castings, and the heating heating element c (10) is a heating sheet installed on the outer sidewall of the mist outlet pipe (9), and the temperature is controlled by a temperature control circuit. When in use, first add an appropriate amount of liquid to be atomized (3) into the atomizing water tank (4), start the machine, and the ultrasonic transducer (2) will work to generate mist, and the airflow generated by the fan (7) will flow the mist out. The mist pipe (9) flows out for treatment and beauty treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com