All-glass solar thermal-collecting tube water separator

A technology of solar collector tubes and water separators, which can be used in solar thermal power generation, solar thermal devices, heating devices, etc., and can solve problems such as failure to obtain thermal states

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

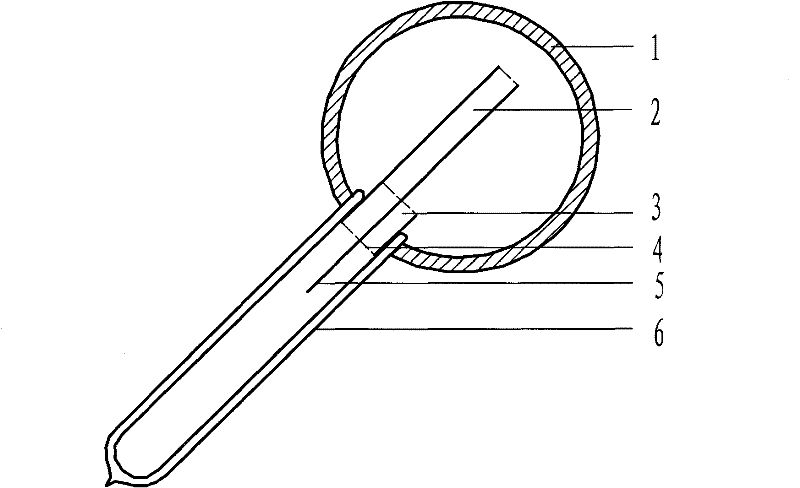

[0036] exist figure 1 In, the specific embodiment of the present invention is expressed in the form of cross-sectional view, illustrating how to install the water separator in the solar water heater.

[0037] The water divider manufactured by applying the present invention is installed at the nozzle of the all-glass solar vacuum heat collecting tube 6, the water dividing tongue 5 is inside, the hot water channel 2 and the cold water channel 3 are outside, and the connecting ring 4 is inserted into the nozzle of the heat collecting tube 6 . The heat collecting pipe 6 installed with the water separator is inserted into the heat collecting pipe hole of the water storage tank 1, and sealed according to the conventional process.

[0038] Before inserting into the water storage tank, the side of the heat collecting tube with the hot water channel 2 needs to be used as the sunny side, facing the direction where the local noon sun is located.

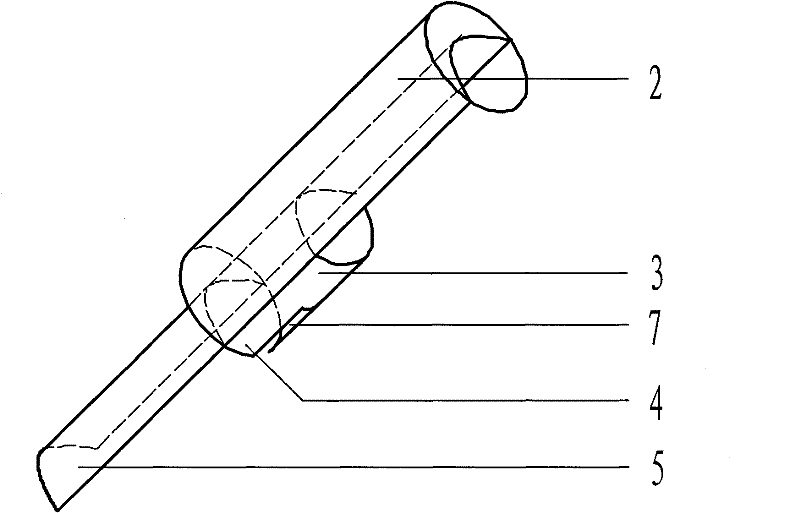

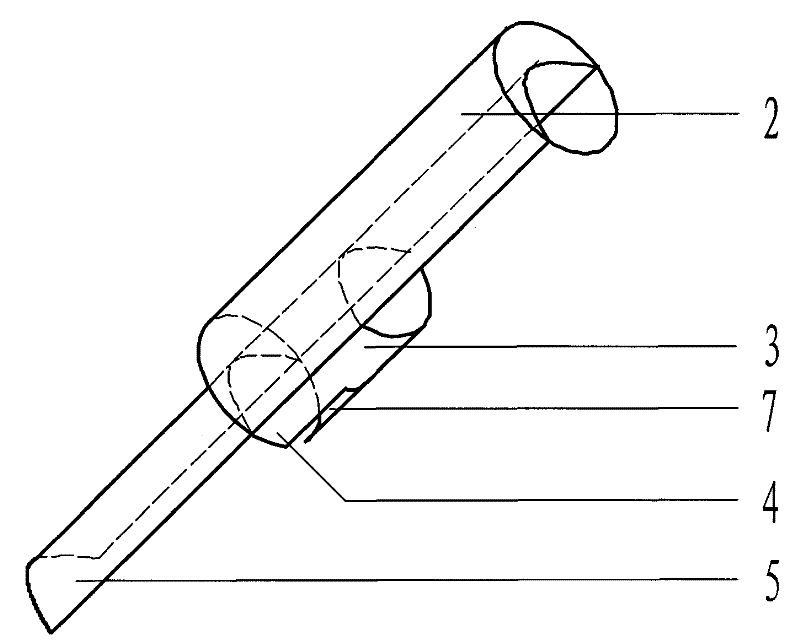

[0039] exist figure 2 In , the speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com