Detection method and equipment for lithium-ion battery pole piece adhesion

A technology of lithium ion battery and testing equipment, applied in the field of lithium ion battery, can solve the problems of large fluctuation of tensile force, deviation of testing results, and difficulty in determining testing results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention and its beneficial technical effects will be described in detail below with reference to the drawings and specific embodiments.

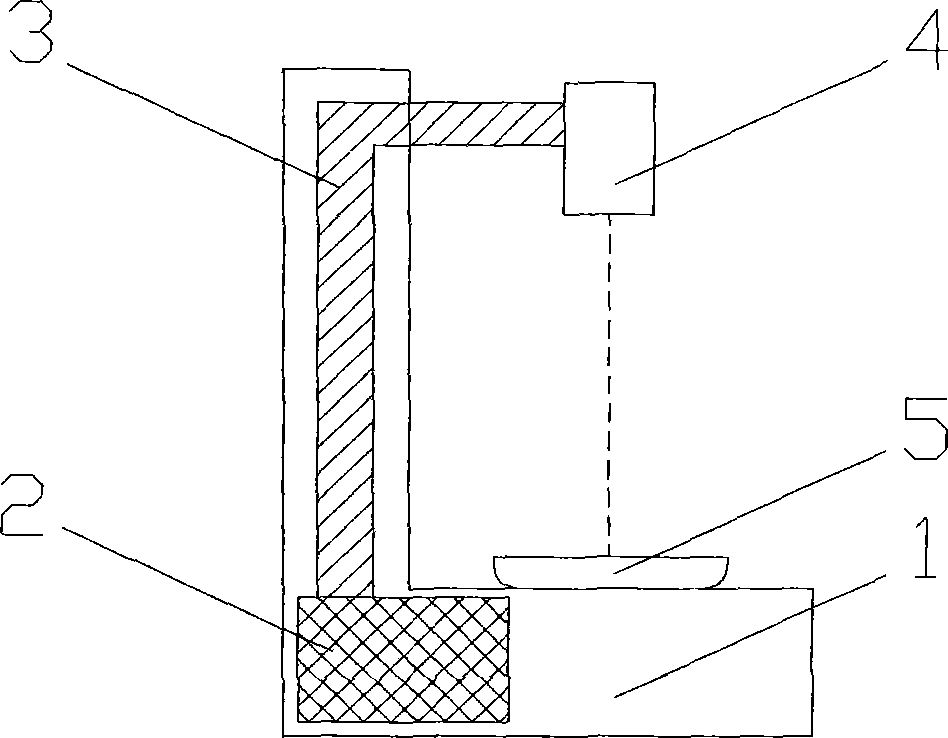

[0033] See figure 1 , The device for testing the adhesion of lithium-ion battery pole pieces of the present invention includes a console 1, an ultrasonic vibrator 2, a vibrating bracket 3, a pattern clamp 4, and a tray 5.

[0034] The ultrasonic vibrator 2 is located inside the console 1. One end of the vibrating bracket 3 is fixedly connected to the ultrasonic vibrator 2 and the other end is fixedly connected to the pattern clamp 4, so that the vibration bracket 3 can directly transmit the vibration from the ultrasonic vibrator 2 Passed to the style fixture 4.

[0035] The tray 5 is located above the operating table 1 and directly below the pattern holder 4, and is used in conjunction with the pattern holder 4 to hold the part of the coating film that has fallen off the pole piece pattern after vibration.

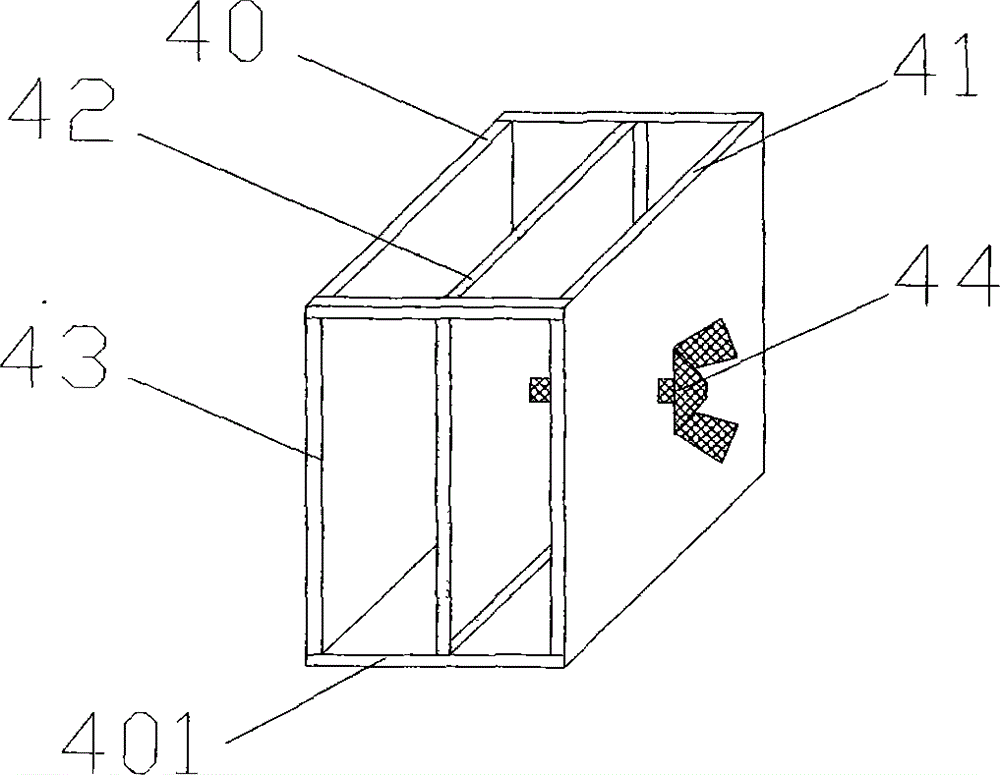

[0036] See figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com