Electric connector for circuit substrate

A technology for circuit substrates and electrical connectors, applied in circuits, connections, fixed connections, etc., can solve the problems of weakened resilience and connector locking function, and achieve the effect of avoiding large-scale and difficult reduction of resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

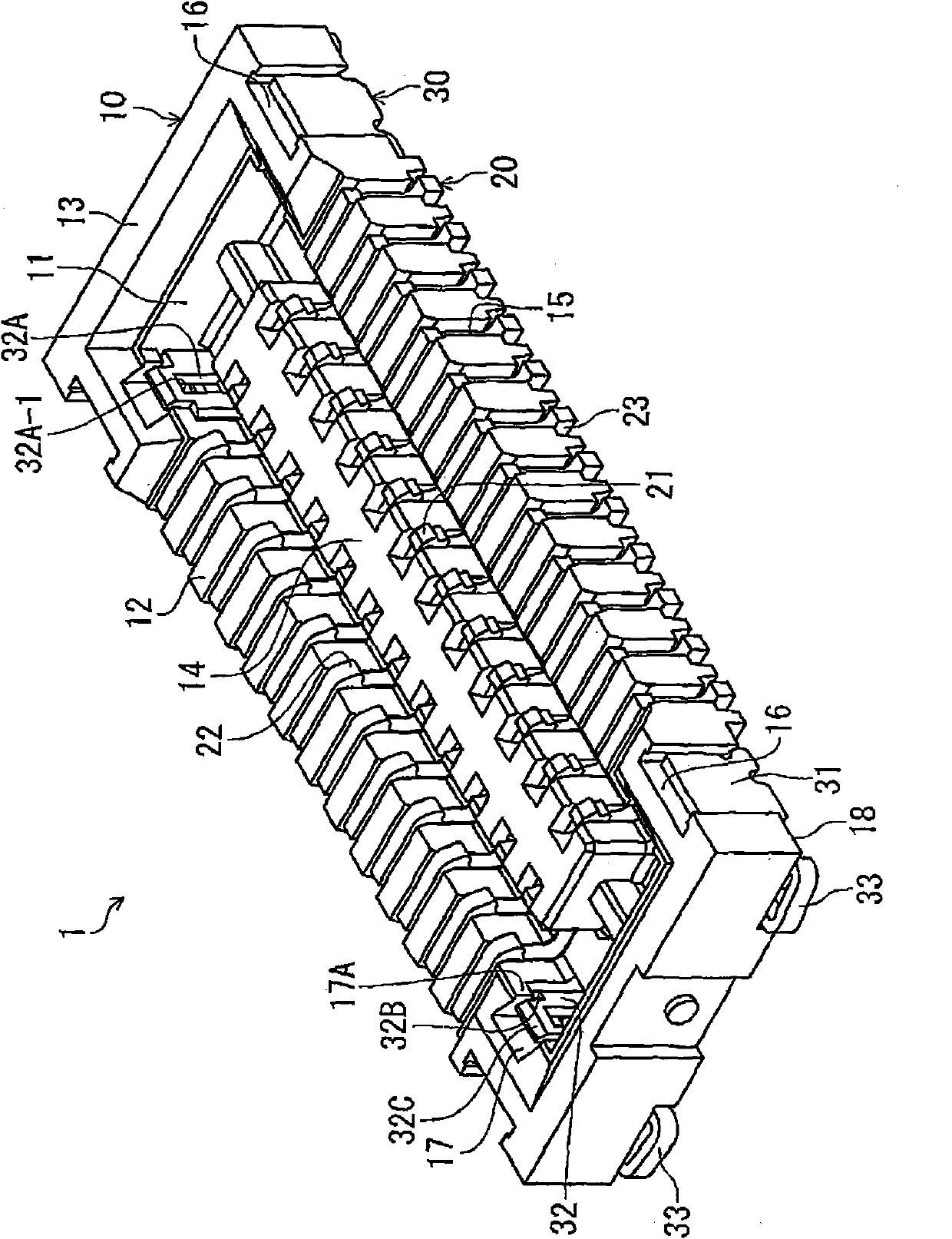

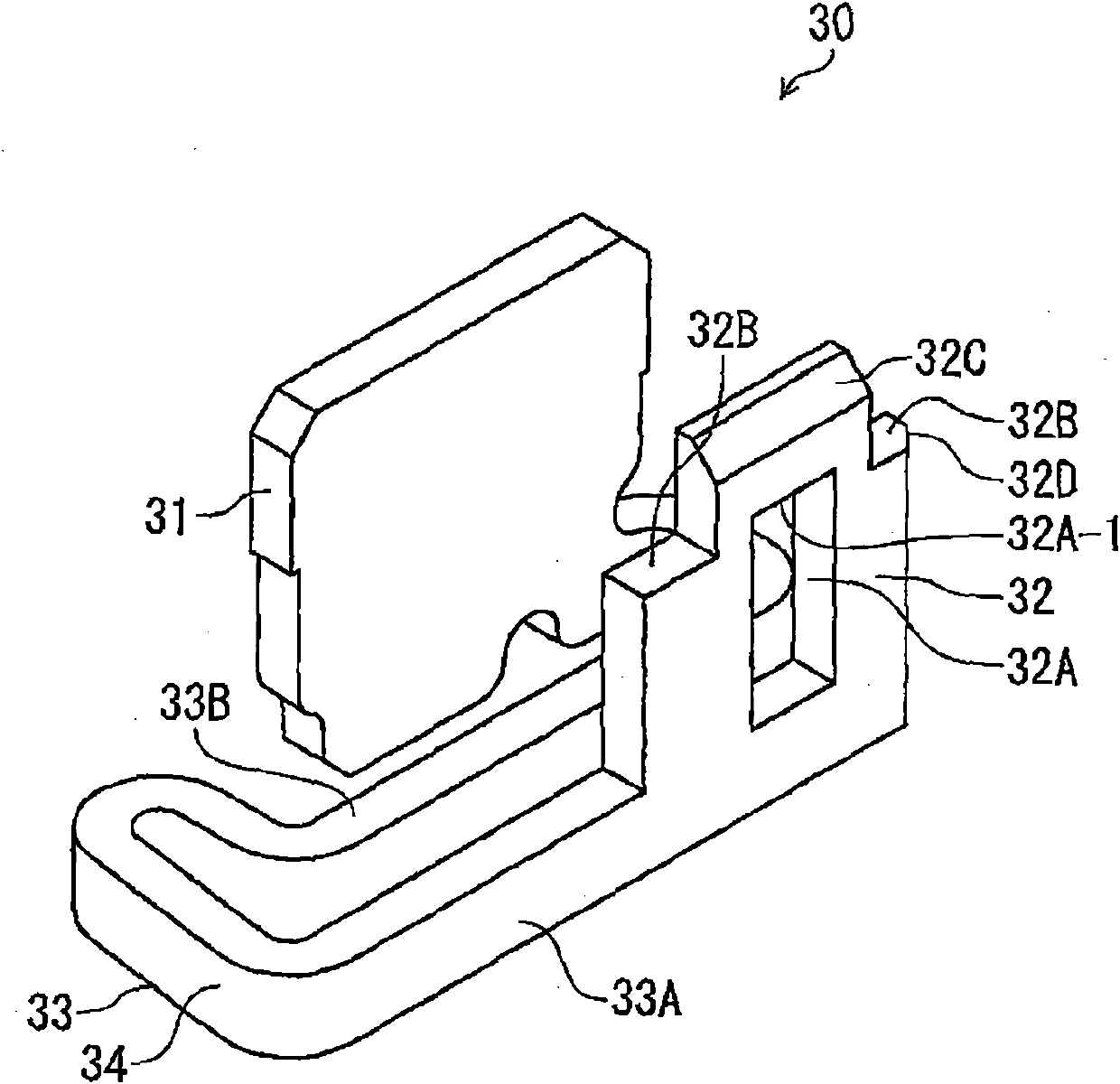

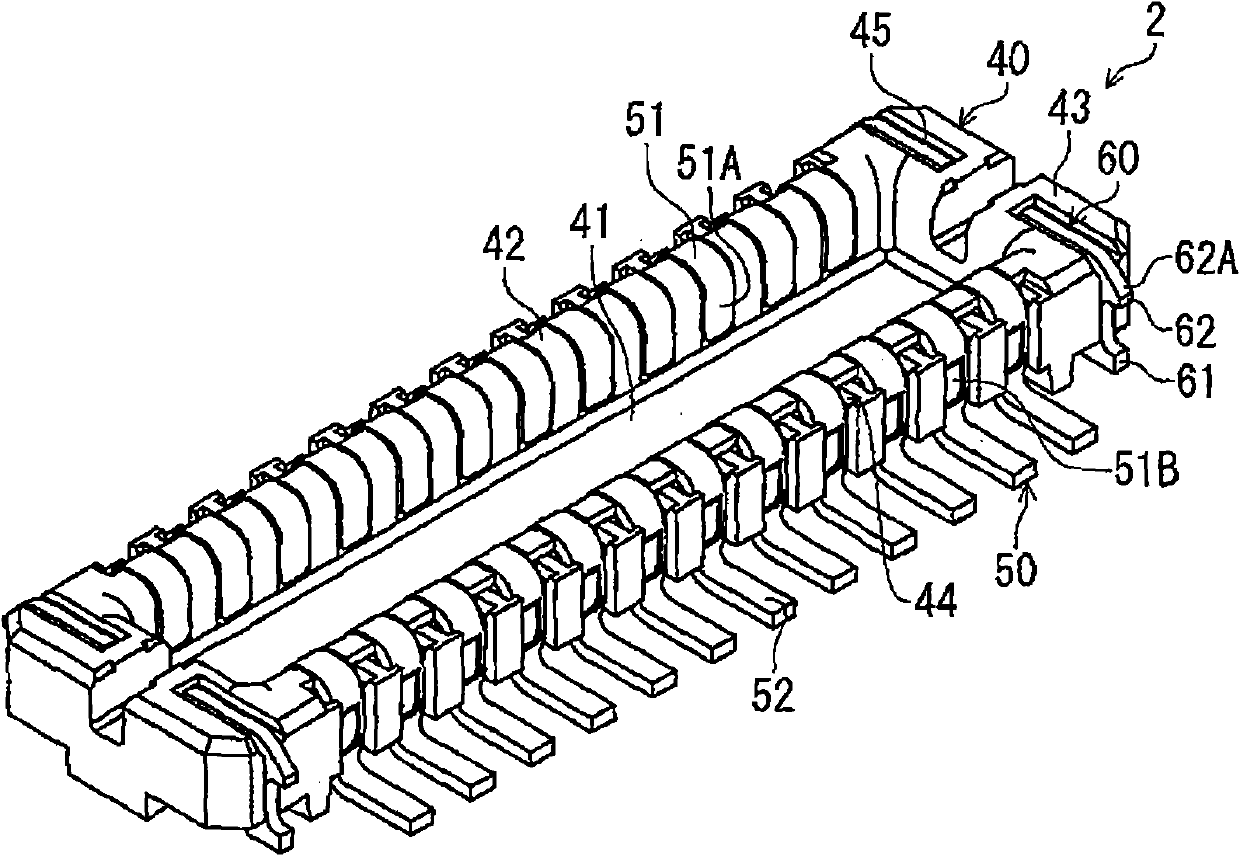

[0040] figure 1 It is a perspective view showing the whole of an electrical connector 1 for a circuit board (hereinafter simply referred to as "connector 1") according to the present embodiment. This connector 1 is an electrical connector disposed on a circuit board (not shown), and has a cover 10 made of an electrical insulating material, such as synthetic resin, into which a mating connector 2 described later is inserted from above. A plurality of terminals 20, the plurality of terminals 20 are arranged and held in the cover 10; a plurality of locking metal parts 30, the plurality of locking metal parts 30 are held in the cover 10 and are matched with the mating connector 2 described later The locking metal piece 60 is locked.

[0041] The cover 10 has a substantially rectangular parallelepiped shape, and is formed with a receiving recess 11 that opens upward, and the mating connector 2 described later is received in the receiving recess 11 from above. The above-mentioned...

no. 2 approach

[0090] The present embodiment is different from the first embodiment in which the displacement of the lock portion is restricted by the restriction portion of the lock metal fitting from the first embodiment in which the displacement of the lock portion is restricted by the restriction protrusion of the cover. The basic configuration of the connector and mating connector in this embodiment is the same as that of the connector and mating connector in the first embodiment; The parts common to those of the first embodiment are denoted by the same reference numerals and description thereof will be omitted. In addition, the locking metal fitting mark will demonstrate the symbol which added "100" to the symbol of the locking metal fitting of 1st Embodiment.

[0091] Image 6 It is a perspective view of the whole lock fitting concerning this embodiment. The locking metal fitting 130 in this embodiment is the same as the locking metal fitting 30 in the first embodiment in terms of b...

no. 3 approach

[0100] The present embodiment is different from the first embodiment in that two lock fitting parts are connected by the bottom plate part. The basic configuration of the connector and mating connector in this embodiment is the same as that of the connector and mating connector in the first embodiment; The parts common to those of the first embodiment are denoted by the same reference numerals and description thereof will be omitted. In addition, the locking metal fitting mark will demonstrate the code|symbol which added "200" to the code|symbol of the locking metal fitting of 1st Embodiment.

[0101] Figure 7 It is a perspective view which shows the whole locking metal fitting which concerns on this embodiment. The lock metal fitting 230 in this embodiment is produced by punching out a metal plate and bending the metal plate in the thickness direction. The locking metal fitting 230 is provided with a held portion 231 , a locking portion 232 , a coupling portion 233 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com