Fault induction self-power-off system for high-end digital printing device

A digital printing, self-power-off technology, applied in electrical components, circuit devices, emergency protection circuit devices, etc., can solve the problems of hurting people, inconspicuous power-off, uncontrolled sliding of the translation stage, etc., to avoid loss of control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

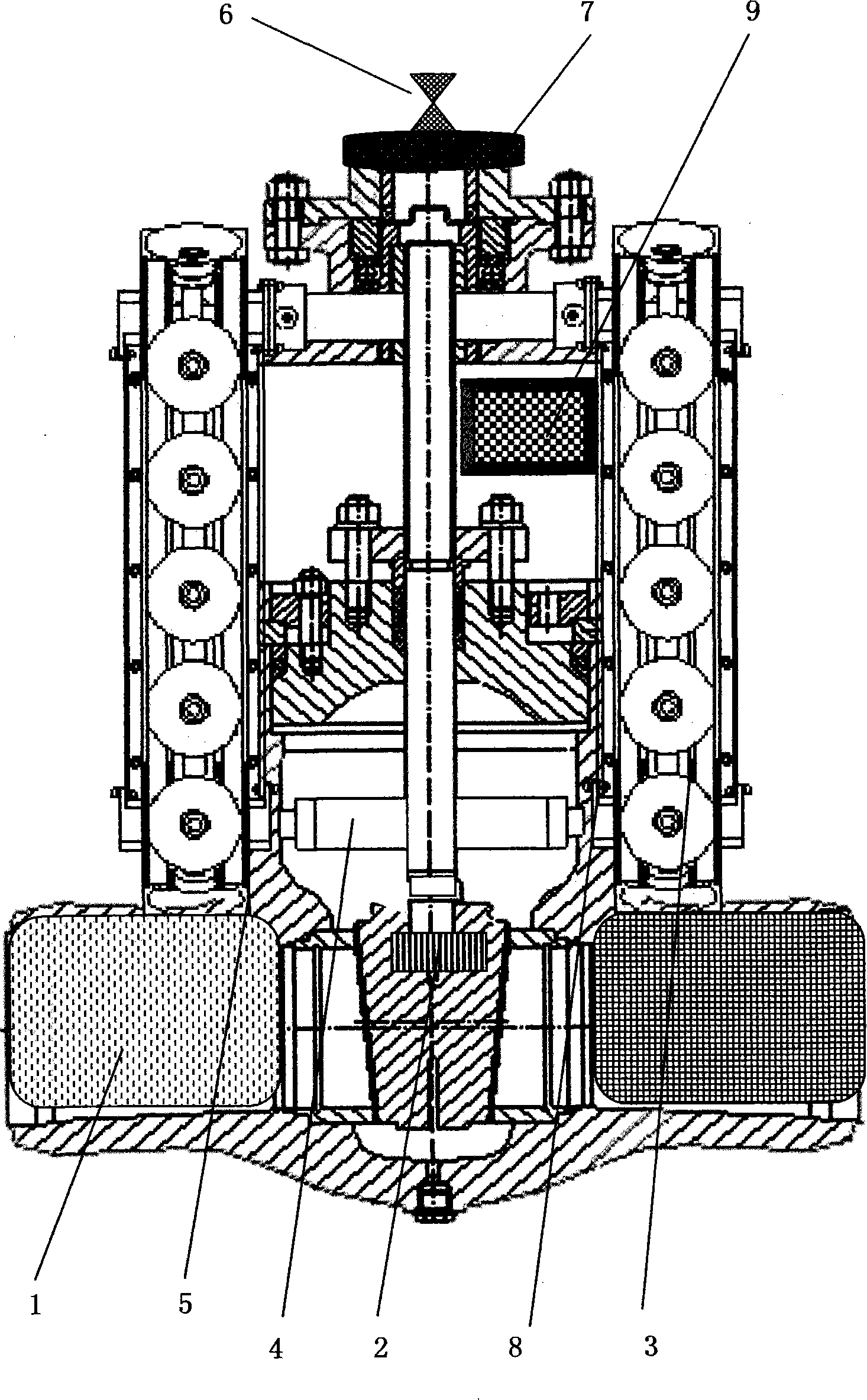

[0009] Such as figure 1 , the fault induction self-power-off system of the high-end digital printing equipment of the present invention includes the electric signal of the encoding disc (1), the motor shaft wheel (2), the synchronous rack (3), the fixed slider (4) and the slider is installed under the slider A guide rail (5) with a synchronous motor, an infrared sensing device (6) is installed on the coding disc electric signal (1), and the infrared sensing device (6) is connected with a controller ( 7)

[0010] In this embodiment, the slider (4) is fixed, the guide rail (5) with a synchronous motor is installed under the slider, the synchronous guide rail (6) with a motor is driven, the controller (7) is set, and there is a power cord (8) An external power supply, an electric code power distribution instrument (9) with a controllable principle (9) and a controller (7) are connected between the infrared sensing device (6) and the power line (8) and are connected to the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com