Safety lifter

A lift and lift mechanism technology, applied in the field of lifts, can solve the problems of out of control of the main table and the limitation of the load capacity of the lift, and achieve the effects of enhanced load-bearing capacity, convenient use and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing and embodiment of description:

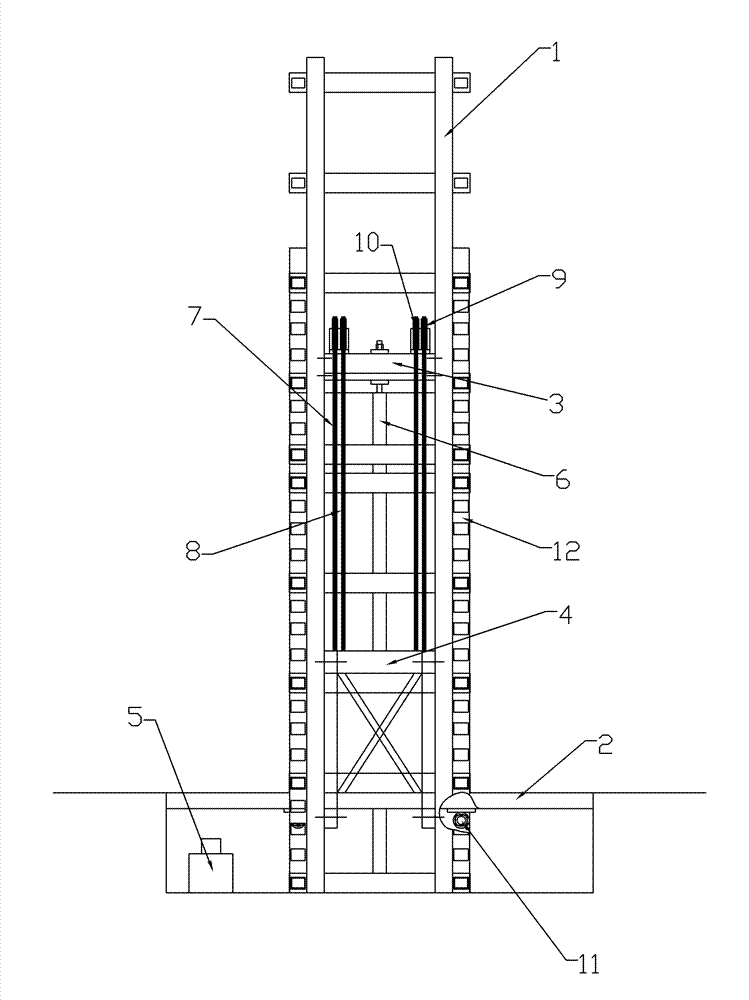

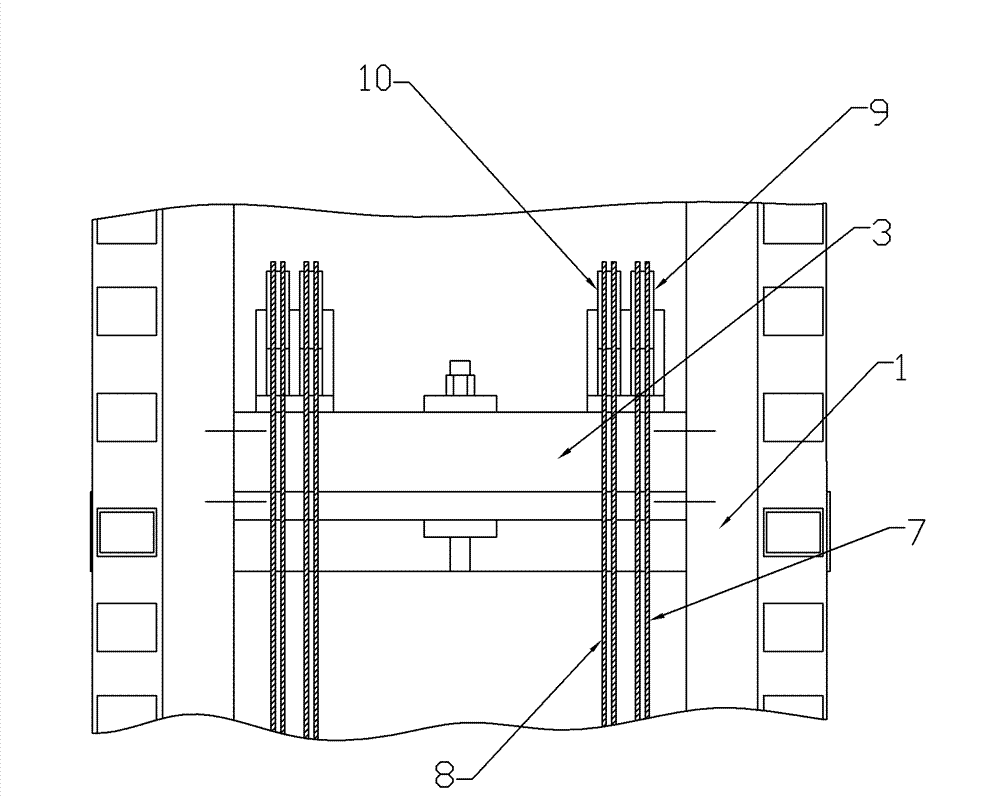

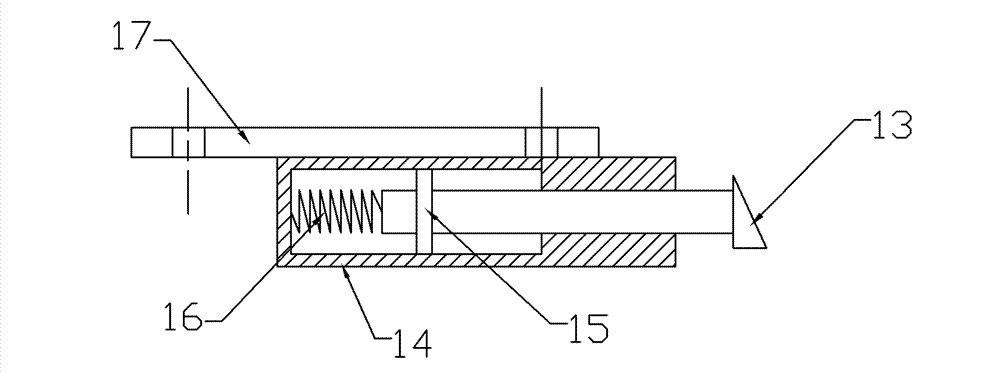

[0016] As shown in the accompanying drawings. A kind of safety hoist, comprises a main platform 2 that runs up and down along a pair of vertically installed track main frame 1, is installed on the lifting mechanism above the main platform 2, hydraulic station 5 and electric control system, and described track main frame 1 is made up of vertical The vertical rods arranged on both sides and the horizontal rods installed in parallel between the two vertical rods are composed. The card channel 12 is symmetrically provided, and the card channel 12 is in the shape of a long strip. The card channel 12 is evenly distributed with rectangular through holes, and the rectangular through holes are matched with the rectangular bumps; A spring hydraulic cylinder 11 is arranged horizontally at the position of the road 12, and the end of the piston rod of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com