Voltage compensation circuit for constant-current system

A voltage compensation and circuit technology, applied in control/regulating systems, electrical components, regulating electrical variables, etc., can solve problems such as poor effect and no real constant current function, and achieve the effect of improving constant current effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

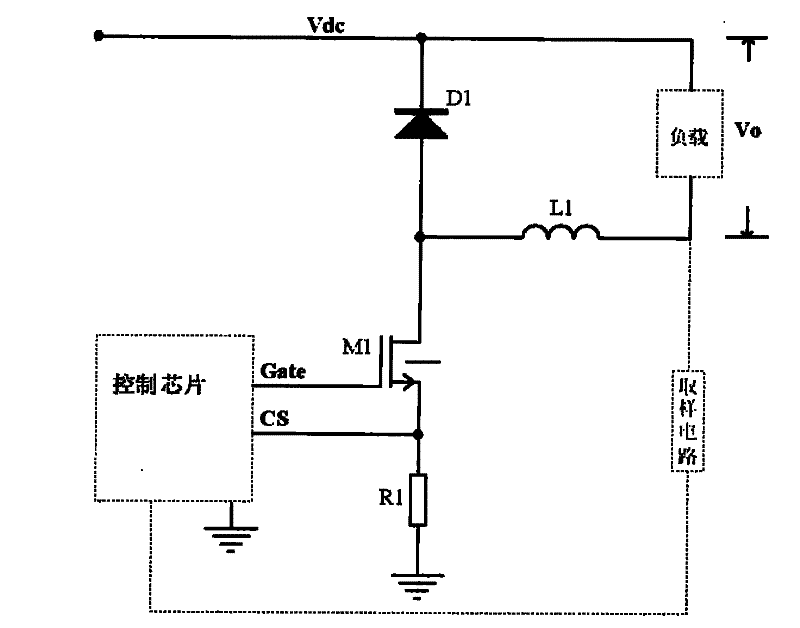

[0033] Figure 4 A structural diagram of a constant current circuit based on voltage compensation according to an embodiment of the present invention. Figure 4 Among them, the constant current circuit includes a control chip 410 , a BUCK topology circuit 420 and a voltage compensation circuit 430 , wherein the voltage compensation circuit 430 includes an output voltage detection circuit 431 and a control circuit 432 .

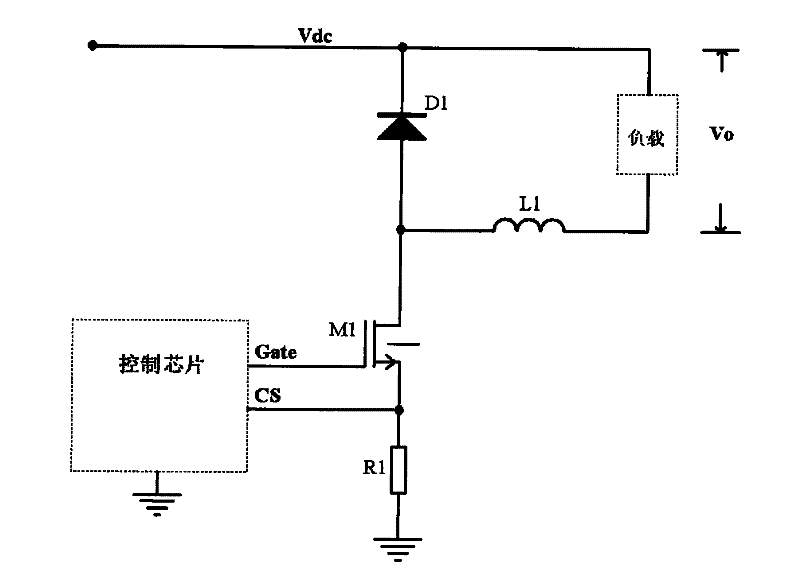

[0034] The BUCK topology circuit 420 includes a load 421 , an inductor L1 , a diode D1 , a switch M1 , and a resistor R1 . Wherein, the load 421 is connected to the diode D1, and the voltage across the load 421 is used as the output terminal voltage Vo; one end of the switch tube M1 is connected to the diode D1, and the other end is connected to the control chip 410 . In one example, the switch tube M1 is a MOS tube. It should be noted that the BUCK topology circuit 420 may be any circuit with a BUCK topology, and is not limited to Figure 4 The connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com